KINGREAL UNIVERSAL IND., LTD

Phone

+86-13702855825| 1 | Importance of Car Center Console Injection Mold Design |

| 2 | Car Center Console Frame Injection Mold Design Process |

| 3 | Advantages of KRMOLD Car Center Console Injection Mold |

| 4 | Common Challenges and Solutions for Car Center Console Injection Mold |

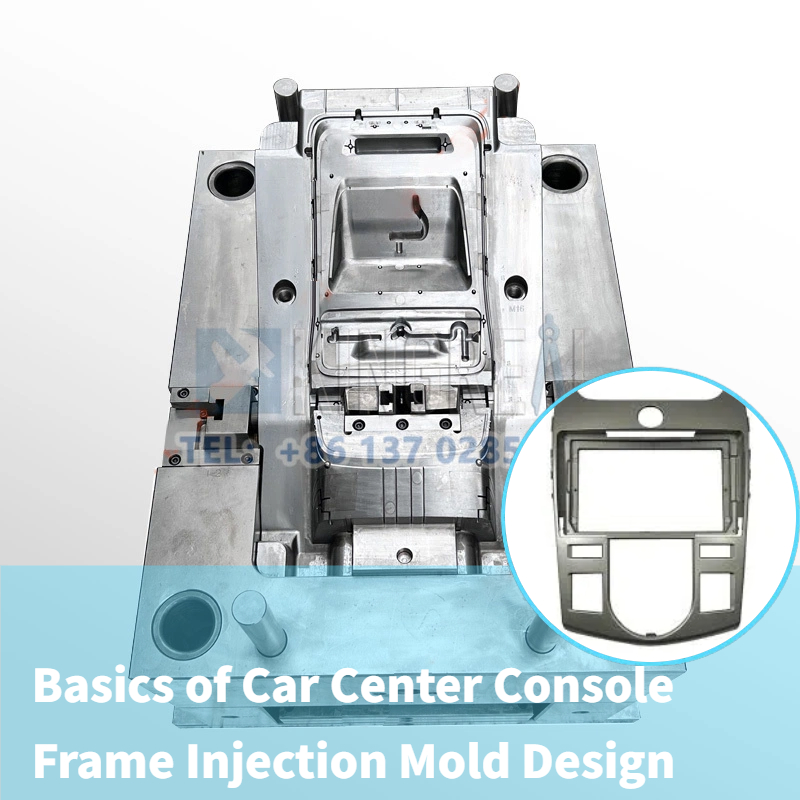

KRMOLD provides customers various types and sizes of car center console frame injection mold. These car center console injection molds are produced through plastic injection molding, which involves injecting molten plastic into a car center console frame injection mold under excessive strain. Once the material cools and solidifies, the car center console injection mold is formed, resulting in a durable, custom-made console frame. This article will provide a detailed introduction to car center console frame injection mold design.

1/ Importance of Car Center Console Injection Mold Design

Car center console frame injection molds are meant to shape raw material—normally plastic—into a strong, multipurpose console. This procedure guarantees that every center console part matches precisely inside the car interior. Without a distinct mold, the finished result may have faults that would influence looks and function. Thus, car center console injection mold design is not only a technical method but also a crucial phase in guaranteeing the quality of automotive interiors.

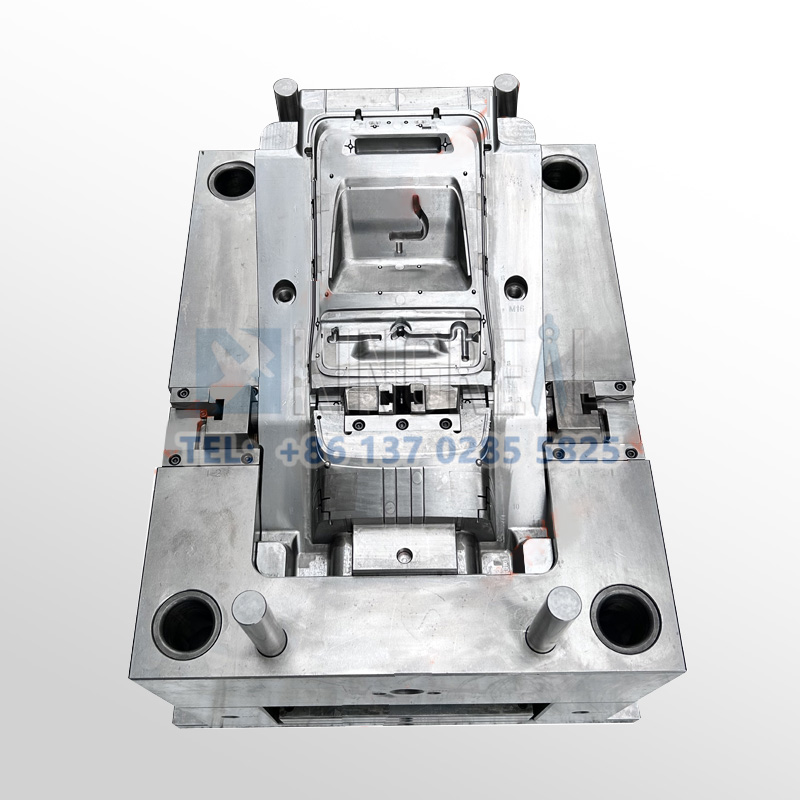

2/ Car Center Console Frame Injection Mold Design Process

The car center console injection mold design process requires careful planning, advanced technology, and a deep understanding of automotive design requirements. KRMOLD engineers utilize advanced software programs and computer-aided design (CAD) structures to create these car center console frame injection molds. Strong and wear resistant, the car center console injection molds have to hold up under regular handling throughout production. The performance of the finished product is directly affected by the caliber of the car center console frame injection mold, therefore guaranteeing that the interior of the automobile meets both protective and cosmetic needs.

When designing a car center console injection mold, engineers need to consider the following aspects:

-Design Shape and Dimensions: The shape and dimensions of the console frame are determined based on the design requirements of the vehicle interior. The mold cavity must be precise to ensure the accuracy of the molded product.

-Cooling System: The mold cooling system is critical to ensuring product quality. A suitable cooling system ensures uniform cooling of the plastic during the molding process, reducing the risk of deformation.

-Material Flowability: The design must consider the plastic's flowability within the car center console frame injection mold to ensure that the material can smoothly fill every part of the car center console injection mold during the injection molding process.

-Venting System: The venting system effectively removes air from the car center console frame injection mold, preventing bubbles and defects.

The complexity of car center console injection mold design requires extensive experience and technical skills from the design team. KRMOLD engineers fully utilize the theory and experience of plastic forming to design a precise cavity shape, ensuring smooth cooling and molding of the car center console frame injection mold.

Mold Material Selection: Material selection plays a crucial role in the durability of automotive center consoles. Plastic is the most commonly used material due to its flexibility, lightness, and cost-effectiveness. The most commonly used plastics include ABS (acrylonitrile butadiene styrene), polypropylene, and polycarbonate. These materials are ideal for automotive interiors due to their strength, impact resistance, and heat resistance.

Fiberglass-reinforced plastic or carbon fiber composites might be used on some ultra-fast cars to improve durability and a premium feel. Although more costly, these materials offer higher wear resistance. Hence choosing materials calls for balancing cost and performance to guarantee the console stays both attractive and functional over the vehicle's life.

3/ Advantages of KRMOLD Car Center Console Injection Mold

1) Improving Product Consistency

Precision car center console frame injection molds significantly improve product consistency. All created consoles will have the same aesthetic and dimensions if every car center console injection mold is made with great exactness. This satisfies brand standards and guarantees uniform assembly techniques.

2) Cost Benefits

Precision car center console frame injection molding design lowers production expenses by speeding up manufacturing, therefore minimizing material waste and product flaws. Well-made car center console injection molds also improve the structural integrity of the finished product, so extending its lifespan and lowering the need for replacements or repairs.

3) Promoting Innovation

High-precision car center console frame injection molds also enable manufacturers to innovate and create precise designs. As market demands change, flexible car center console injection mold designs can quickly adapt to new product development and improve production line utilization.

4/ Common Challenges and Solutions for Car Center Console Injection Mold

During the design process for car center console frame injection molds, engineers may face various challenges, such as molding defects, poor material flow, and uneven cooling. KRMOLD offers a range of solutions to address these challenges:

-Molding Defects: By optimizing car center console injection mold design and adjusting plastic injection molding parameters, defects such as bubbles and short shots can be effectively reduced.

-Material Flow Issues: During the car center console frame injection mold design phase, engineers perform flow analysis to ensure good material flow within the car center console injection mold.

-Cooling Control: Designing an efficient cooling system ensures uniform temperature distribution within the car center console injection mold, reducing the risk of deformation during the molding process.