KINGREAL UNIVERSAL IND., LTD

Phone

+86-13702855825| 1 | Introduction to Automotive Dashboard Injection Mold |

| 2 | Design Considerations of Car Dashboard Injection Mold |

| 3 | Materials for Car Dashboard Injection Mold |

In the painstaking workmanship of automobile manufacture,automotive dashboard injection molds are absolutely vital. The automotive dashboard directly affects the driver's visual experience and ease of use as part of the car's interior, therefore influencing comfort and practicality of the car. Hence, to provide a working and aesthetically pleasing car dashboard, the design and creation of car dashboard injection molds calls for advanced technologies and demanding criteria, offering the driver a secure and cozy driving experience.

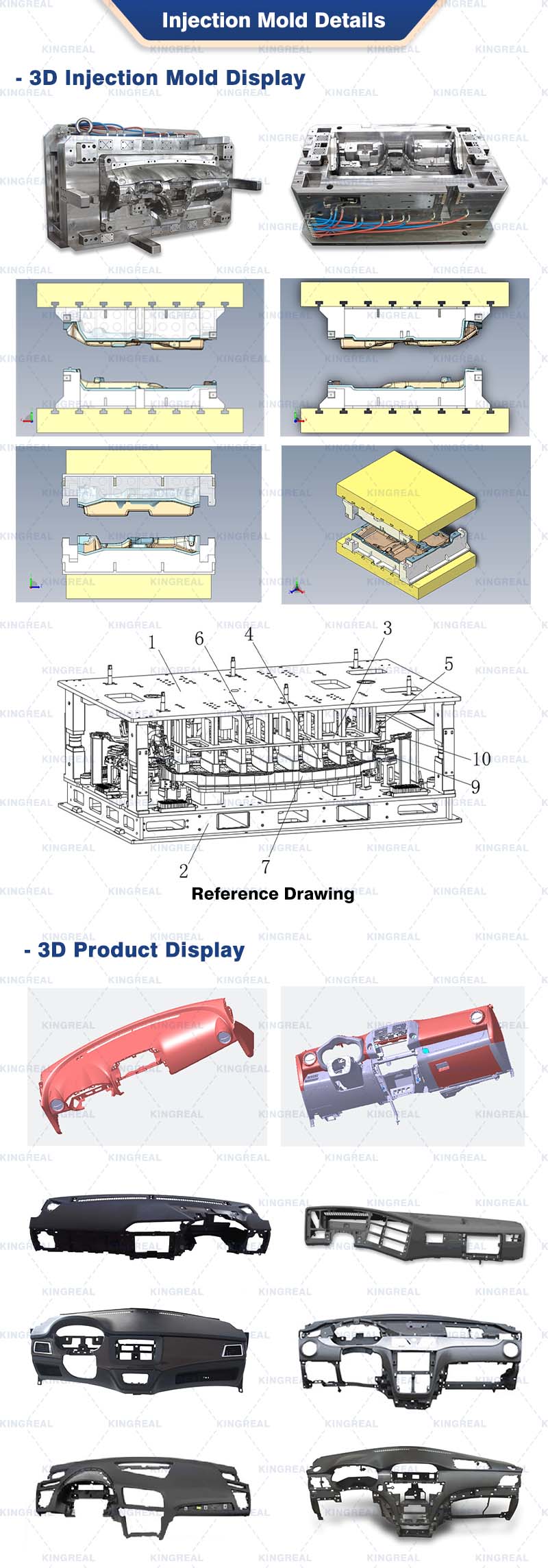

1. Introduction to Automotive Dashboard Injection Mold

Car dashboard injection molding design and production differs in the automotive manufacturing industry from conventional injection molds. This shows especially in the increased demands for accuracy, materials, and workmanship. The design and production of automotive dashboard injection molds must be subjected to exact calculations and extensive testing in order to create a safe and pleasant driving environment. Make certain all particulars fulfill demanding specifications.

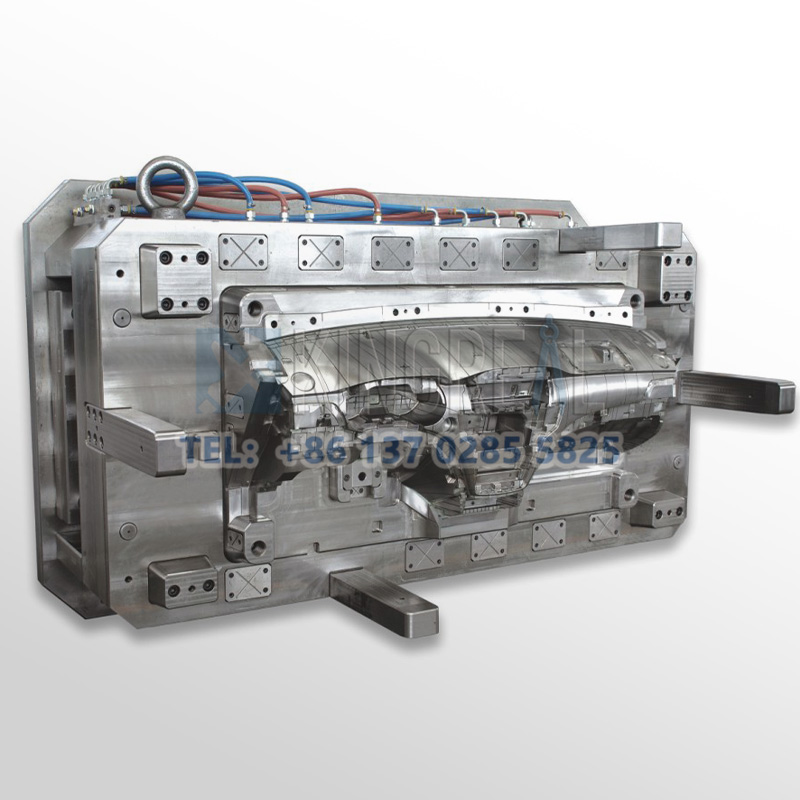

● Injection Molding Machine Requirements

High-tonnage injection molding tools are usually needed for car dashboard injection molds. Transverse injection molding is sometimes employed during manufacture when the automotive dashboard injection mold size of the vehicle is big. By guaranteeing consistent plastic flow inside the car dashboard injection mold, this design lowers the chance of bubbles and blemishes.

● Car Dashboard Components

The automotive dashboard assembly mainly comprises several elements including storage, defroster ducts, air vents, instrument cluster shroud, and top and lower vehicle dashboard bodies. ash tray, center console, glove box, compartment These parts combine to create significant decorative and functional elements within the vehicle interior that assist the driver's several needs while driving.

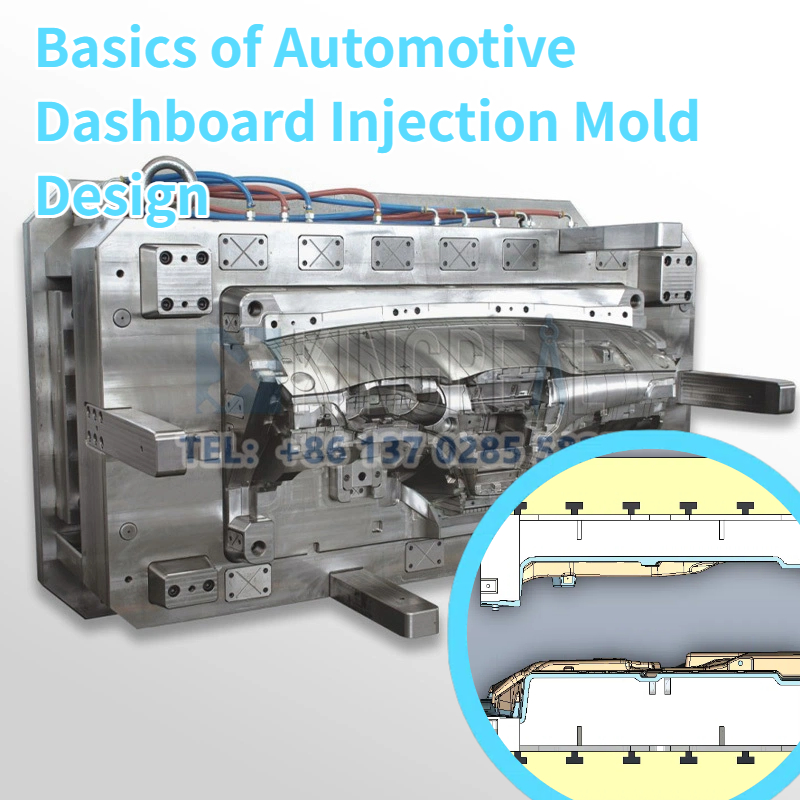

2. Design Considerations of Car Dashboard Injection Mold

Complex in design and production, automotive dashboard injection molds demand close awareness to many of particulars. Engineers have to make sure the automobile dashboard made by the car dashboard injection mold has exact proportions and a great surface finish.

● Dimensional accuracy for car dashboard injection mold

Dimensional accuracy is a core element of automotive dashboard injection mold design. The car dashboard's dimensions must perfectly match the vehicle's internal structure to avoid problems during assembly. High-precision car dashboard injection molds reduce post-production adjustments and trimming, improving production efficiency.

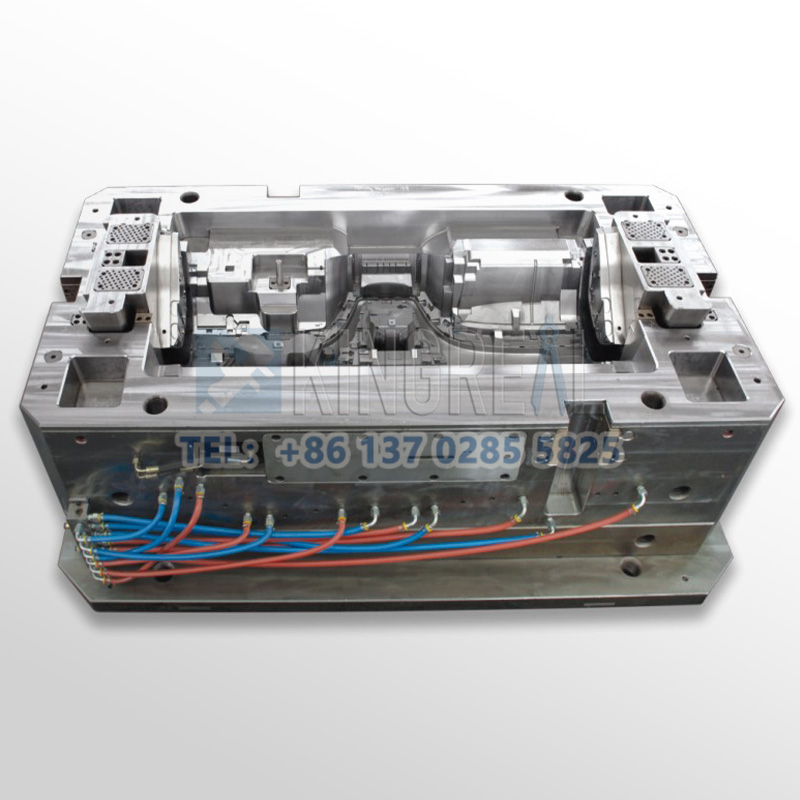

● Cooling performance for car dashboard injection mold

Cooling performance is another key issue. A well-designed cooling system within the automotive dashboard injection mold ensures faster manufacturing cycles and prevents defects such as warping. A sound cooling design effectively reduces mold temperature and improves production efficiency.

● Surface treatment for car dashboard injection mold

In automobile dashboard injection mold design, surface treatment is also vital. High-quality car dashboard injection mold surface treatment helps the ultimate product to look beautiful and improves its market competitiveness. Therefore, the design of automotive dashboard injection mold must take surface finish, wear resistance, and corrosion resistance into account.

● Gating and ventilation devices for car dashboard injection mold

Proper gates and venting equipment are critical in car dashboard injection molding design. These designs remove trapped air and avoid imperfections by guaranteeing seamless plastic flow throughout injection into the car dashboard injection mold. Good gate design also helps to minimise waste and maximise material use.

● Automotive Dashboard Injection Mold Durability

The lifespan of the car dashboard injection mold directly impacts manufacturing efficiency and costs. Good materials and careful design can help to increase the automotive dashboard injection mold's lifespan and reduce production expenses. Hence, choosing the correct material and using great workmanship are absolutely essential throughout car dashboard injection mold development and manufacturing.

3. Materials for Car Dashboard Injection Mold

Car dashboard injection mold materials must be strong, heat-resistant, and durable to meet the high standards required for car dashboard injection molds. High-quality automotive dashboard injection molds ensure a simple production system and minimize defects.

● High-grade Metals

Because of their strength, heat resistance, and durability, high-grade metals are the most frequently utilized automotive dashboard injection molding materials. Widely employed are metals including P20, H13, and S136. These materials are perfect for long-term production runs because they have great wear resistance in addition to high temperature tolerance.

● Aluminum

Aluminum is an ideal car dashboard injection mold material. Although not as strong as some metals, it is lightweight and easy to process, making it suitable for small-batch production. Using aluminum molds can effectively reduce production costs, especially when demand is low.

● Nickel Alloys

Nickel alloys offer high corrosion resistance and durability, making them ideal for long-life automotive dashboard injection molds. They excel in high-temperature and high-pressure environments, effectively extending the life of the car dashboard injection mold.

● Thermoplastics

Thermoplastics are sometimes used to manufacture automobile dashboards. ABS (acrylonitrile butadiene styrene) is a popular material for its superior impact resistance and surface finish. High temperature resistance and toughness characterize polycarbonate/ABS (PC/ABS) blends, which make them ideal for more sophisticated designs.

● Polypropylene (PP)

Its inexpensive weight and versatility lead to widespread use of polypropylene. It produces great results in terms of durability and appearance of the completed product in addition to performing well during the injection molding process. Offering better support for car dashboards, high-power packaging requiring great toughness uses glass fiber reinforced plastics.