KINGREAL UNIVERSAL IND., LTD

Phone

+86-13702855825American Customer Visited KRMOLD Factory

Recently, KRMOLD warmly welcomed a customer from the United States to visit the factory. Prior to this, the KRMOLD team had conducted in-depth online communications with this customer many times. The customer already had a certain understanding of KRMOLD's plastic injection mold manufacturing capabilities. The main purpose of this visit was to evaluate whether KRMOLD could meet its specific needs in the automotive manufacturing industry, especially rearview mirror reflective injection mold.

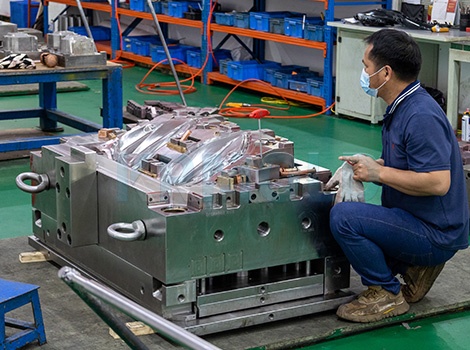

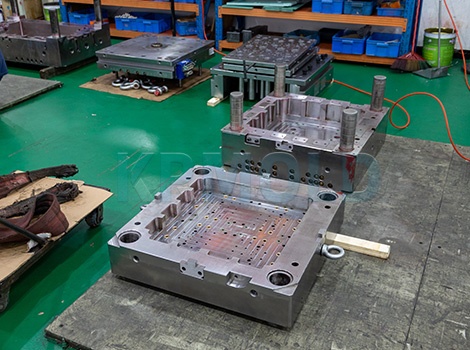

During the factory visit, KRMOLD sent professional staff to accompany the whole process and lead the customer to the car rearview mirror shell mould manufacturing workshop. The staff introduced in detail the various equipment in the workshop, including CNC machine, EDM, wire cut machine, fitting machine, mill machines, lathe machine, mold closing machines, drill machine, CMM, projection machine, rigidity machine and injection machine. KRMOLD emphasized that these machines are selected from well-known domestic and foreign brands, with excellent performance and precise parameters, providing a solid guarantee for the efficient production of car rearview mirror shell mould.

In addition, the staff also explained in detail the manufacturing process of car rearview mirror shell mould. KRMOLD will select the appropriate mold material according to the characteristics and production batch of American customers' products. Commonly used materials include steel, aluminum and alloys. CNC technology is used in the initial processing to process the basic shape of the rearview mirror reflective injection mold according to the design drawings. Subsequently, for complex cavities and fine structures, KRMOLD's team uses EDM for fine processing to ensure the high precision of the car rearview mirror shell mould. Then, the mold surface is processed through grinding technology to improve the surface finish, reduce friction during rearview mirror reflective injection molding, and ensure the quality of the final product.

After the processing of each component of the rearview mirror reflective injection mold is completed, KRMOLD staff will assemble it, including the cavity, core, guide rod, spring, etc., to ensure that all components can fit correctly. After assembly, KRMOLD will conduct preliminary debugging of the rearview mirror reflective injection mold to check whether the fit and movement of each component are smooth. Next, the assembled car rearview mirror shell mould will be installed on the injection molding machine for mold trial, observe the molding effect, and check the size, appearance and performance of the product. According to the results of the mold trial, KRMOLD will make necessary adjustments and optimizations to ensure that all parameters meet the design requirements. KRMOLD particularly emphasized that if the mold trial results do not meet the parameters specified in the plan, the team will make timely modifications and ensure on-time delivery.

KRMOLD Provided a Customized Injection Mold Manufaturing Solution

After the visit, KRMOLD also invited American customers to the conference room for more in-depth communication with engineers. The engineers first demonstrated the successful cooperation cases with other customers in the automotive industry, and introduced the friendly cooperation relationship between KRMOLD and multinational customers and rich project experience to American customers.

During the meeting, the engineer carefully asked the customer about the production needs, including the size specifications of the rearview mirror cover, the requirements for the type and characteristics of plastic materials, whether the production quantity is large or small batches, and whether there are specific injection molding process requirements (such as multi-cavity molds, cold runners or hot runners, etc.). After full communication, the engineer finally provided the customer with a customized car rearview mirror shell mould manufacturing plan and preliminarily finalized the delivery time.

This factory visit not only deepened the customer's understanding of KRMOLD, but also laid a solid foundation for future cooperation. KRMOLD looks forward to working with customers to create a better future together.