KINGREAL UNIVERSAL IND., LTD

Phone

+86-13702855825| 1 | Parameters of Car Center Console Frame Injection Mold |

| 2 | Car Center Console Frame Mold Design |

| 3 | Advantages of Car Center Console Frame Mold |

The car center console frame injection mold can mass-produce the core components such as the frame body, panels and various functional buttons of the automobile center console, providing basic support for the assembly of the automobile interior. Because the automobile center console frame needs to bear and fix various electronic components such as air conditioning system, audio equipment, display screen, etc., car center console frame mold has strict requirements on structural strength and use stability. Therefore, in the production process of car center console frame injection mold, glass fiber reinforced engineering plastics are usually used as raw materials, among which reinforced nylon (PA) has become a common material in the production of this kind of mold because of its excellent mechanical properties, so as to ensure that the molded center console frame can meet the use requirements. After the precise injection molding is completed by car center console frame mold, the products need to be treated by surface treatment processes such as painting, electroplating or in-mold decoration (IMD), so as to achieve rich color matching and diverse texture effects and match the interior design styles of different models.

1.Parameters of Car Center Console Frame Injection Mold

| Model | customized as required |

| Number of cavities | 1 out of 1 |

| Mold base | LKM, ISM standard, HASCO or according to customer requirements. |

| Mould material | P20, 718H, H13, 2344, 2316, NAK80. |

| Mold runner system | cold runner/hot runner |

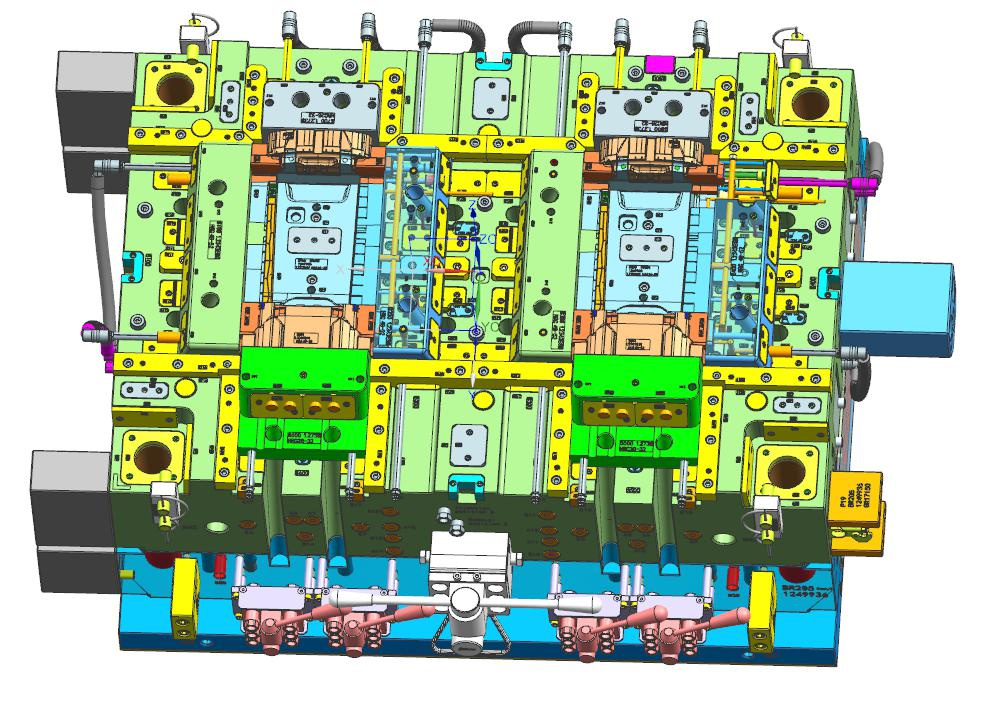

| Design software | UG; PROE; CAD |

| Plastic materials | PP, ABS, HDPE, PC, PVC, PA6, PA66, PEETC. |

| Die life | 500,000 -3,000,000 times. |

| Mold size | according to product design |

| Mold weight | according to product design |

| Sample | according to product design |

2.Car Center Console Frame Mold Design

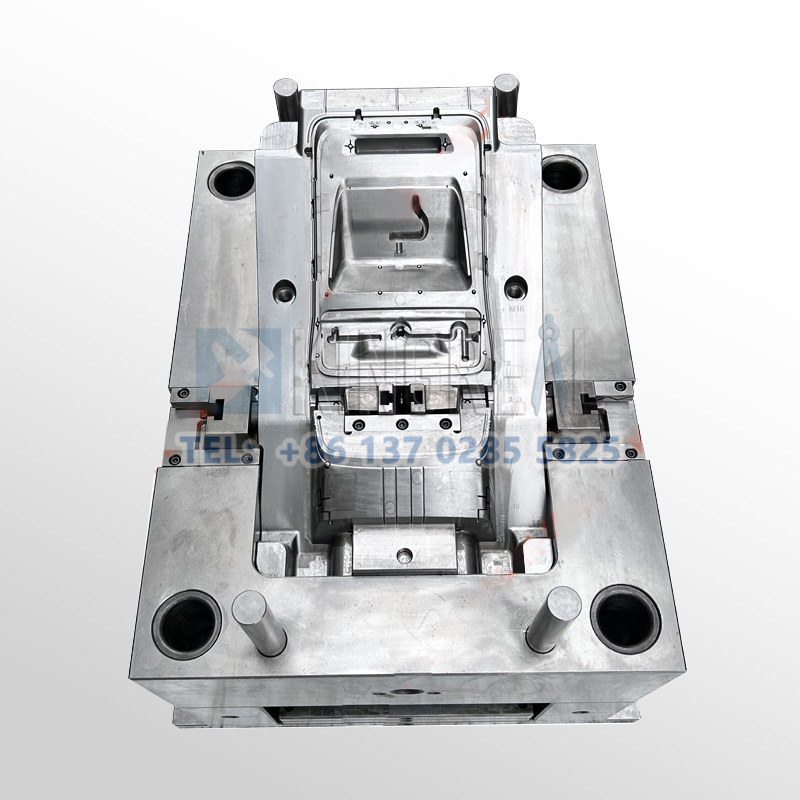

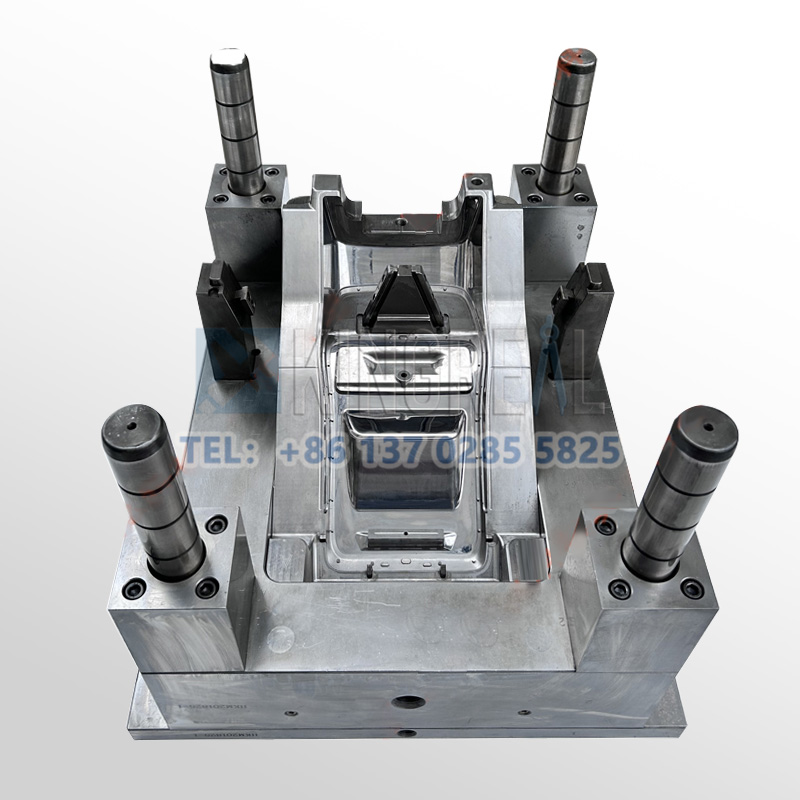

2.1 Structural design of car center console frame mold

The automobile center console frame is mostly irregular in shape, and contains many concave-convex structures and buckles. Therefore, the structural design of the car center console frame injection mold should fully consider these complex features to ensure that the key parts such as deep cavities and narrow seams can be demoulded smoothly, so as to avoid problems such as product galling and deformation; At the same time, it is necessary to strictly control the uniformity of the wall thickness of the mold cavity to prevent the molded product from producing defects such as miniature or bubbles.

2.2 Selection of car center console frame mold materials

The mold cavity is in direct contact with molten plastic, which requires high hardness and high polishing. The car center console frame injection mold cavity is usually made of materials such as 718H and NAK80, which can effectively improve the wear resistance of the car center console frame mold, ensure the surface smoothness of the molded product and meet the appearance requirements of the automobile interior.

2.3 Gating system of car center console frame mold

In order to ensure that molten plastic can fill the car center console frame injection mold cavity evenly, the gating system of the car center console frame mold often adopts multi-point glue feeding design, so as to reduce the weld mark of the product and improve the structural strength; In addition, the gate position should avoid the appearance surface and stressed parts of the product to avoid affecting the aesthetics and performance of the product.

2.4 Cooling and demoulding system of car center console frame mold

The design of the cooling system should ensure that the cooling water path fits the surface of the cavity, ensure the uniform temperature of all parts of the car center console frame injection mold, and prevent the molded product from warping and deformation due to uneven cooling; The demoulding mechanism needs to ensure uniform strength to avoid leaving top marks on the product surface or causing product deformation.

3.Advantages of Car Center Console Frame Mold

3.1 High-precision and complex structure adaptability for car center console frame mold

The car center console frame injection mold should meet the accuracy standard with tolerance within ±0.1mm, and at the same time, it should be suitable for complex structures such as multi-inversion, deep cavity and narrow seam on the center console frame, such as instrument card buckle and function button installation position. In order to ensure the product quality, this kind of car center console frame injection mold often adopts hot runner system and multi-point glue feeding technology to ensure that the melt is evenly filled in the cavity and reduce defects such as weld marks and shrinkage marks.

3.2 High adaptability of materials and technology for car center console frame mold

The car center console frame injection mold can be compatible with ABS, PC/ABS alloy, TPO and other engineering plastics. In some scenes with higher strength requirements, it is necessary to adapt to the injection molding of glass fiber reinforced materials. According to the requirements of high-gloss or dermatoglyphic appearance of products, high-gloss polished steel such as 718H and S136 should be used in the car center console frame mold cavity, or special surface treatment technology should be adopted to ensure that the molded products can achieve the designed appearance effect.

3.3 Intelligent and efficient production of for car center console frame mold

The car center console frame injection mold integrates many advanced technologies, such as CAE mold flow analysis technology, which can simulate the injection process in advance and optimize the mold structure design; 3D printing conformal waterway technology can greatly improve the cooling efficiency and shorten the production cycle by 20%-30%. In addition, some car center console frame mold are equipped with automatic core-pulling mechanism, such as the core-pulling structure of inclined guide pillar and oil cylinder, which can realize synchronous demoulding of complex inverted parts and further improve production efficiency and product stability.