KINGREAL UNIVERSAL IND., LTD

Phone

+86-13702855825General Content:

1. Basic Concepts of Automotive Lighting Injection Mold

2. Car Headlight Injection Mold Design Process

3. High-Precision Machining Equipment for Car Headlight Injection Mold

4. Mold Cooling System Design

5. Car Headlight Injection Mold Quality Inspection

6. Customized Services for Car Headlight Injection Mold

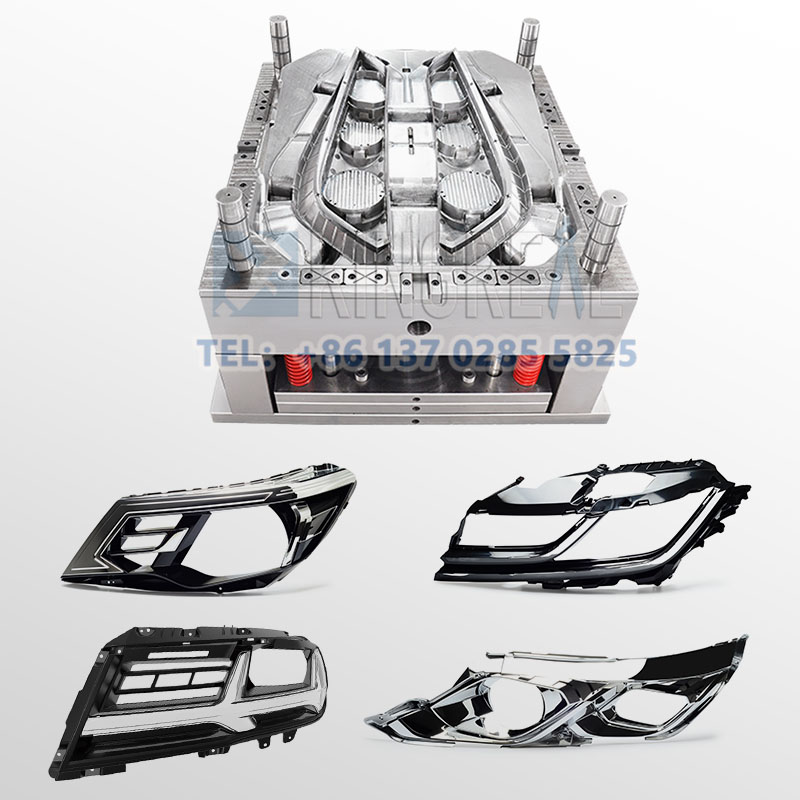

Automotive lighting injection molds are specifically designed to produce various frames that support automotive lights. These car headlight injection molds are widely used in the installation of automotive lamps of different types and sizes, and are crucial equipment for ensuring the proper appearance and function of the lights. As an experienced manufacturer of automotive lighting injection molds, KRMOLD is committed to providing customers with high-quality car headlight injection mold solutions. This article will provide a detailed introduction to the basic knowledge, design and manufacturing process, and quality inspection of automotive lighting injection molds, helping you gain a deeper understanding of this field.

1. Basic Concepts of Automotive Lighting Injection Mold

Car headlight injection molds are tools specifically used to manufacture automotive lighting components, including headlights, taillights, turn signals, etc. In the automotive industry, the appearance and performance of lamps are paramount, therefore, the design and manufacturing requirements for automotive lighting injection molds are exceptionally stringent.

●Main Components Car headlight injection molds typically consist of several parts, mainly including: Left and right lenses: Protect the internal components of the lamp and ensure more even light distribution. -Left and right decorative frames: Provide an aesthetically pleasing appearance for the lamp and increase structural stability. -Left and right lamp housings: Ensure the structural integrity of the lamp and typically require good heat resistance and water resistance. -Left and right reflectors: Improve the luminous efficacy of the lamp, allowing the light to fully perform its illumination function. |  |

2. Car Headlight Injection Mold Design Process

2.1 Mold flow analysis for automotive lighting injection mold During the product design phase, KRMOLD engineers conduct mold flow analysis to determine the optimal injection method and the location and number of injection points. This process is a crucial step in the design of car headlight injection molds, ensuring the molding quality of the plastic parts.

2.2 Selection of mold steel for automotive lighting injection mold KRMOLD uses high-quality mold steel imported from Germany to ensure the durability and stability of the car headlight injection molds during use. High-quality steel not only extends the automotive lighting injection mold's lifespan but also ensures that the finished product meets industry standards. |  |

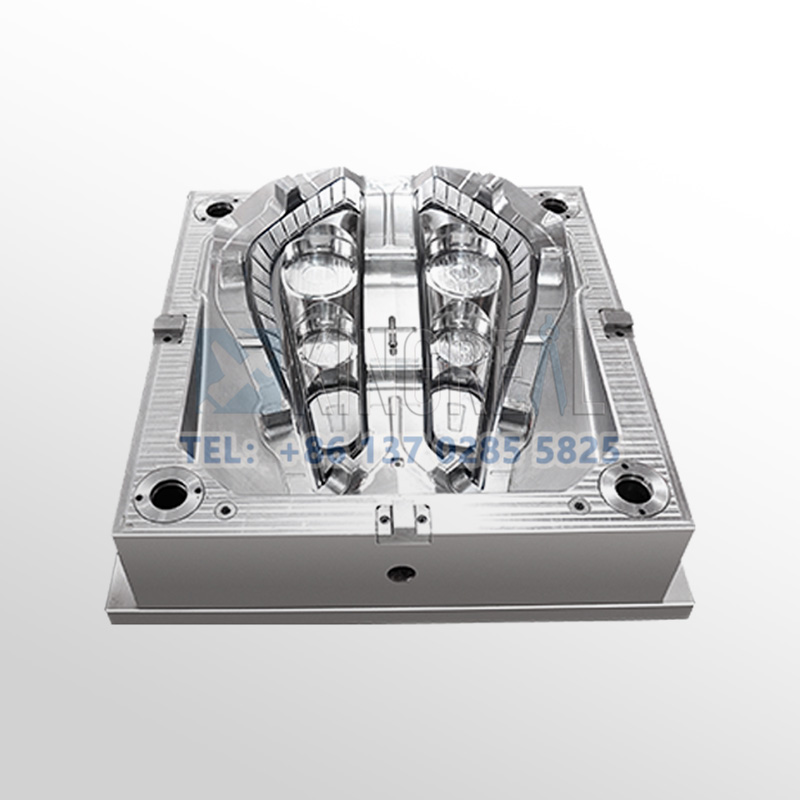

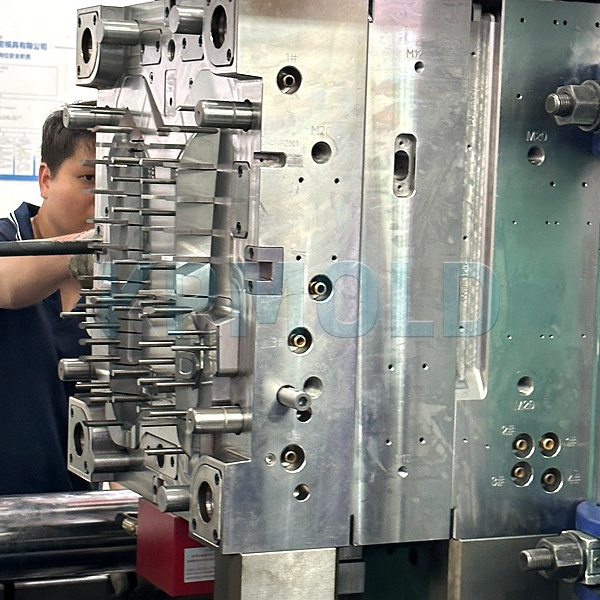

3. High-Precision Machining Equipment for Car Headlight Injection Mold

Mold machining utilizes high-precision imported equipment, such as the Italian Fadia high-precision five-axis CNC milling machine and the Japanese Shaddick mirror EDM machine. The use of this equipment better ensures the surface gloss of the product, thereby reducing the need for subsequent polishing and improving production efficiency.

After mold machining is completed, KRMOLD also equips the automotive lighting injection mold with two coordinate measuring machines and one projection measuring instrument to ensure the dimensional accuracy of the car headlight injection mold. These measuring devices precisely measure the cavity, core, and other components to ensure every indicator is within control limits.

4. Mold Cooling System Design

The cooling system is a crucial component of automotive lighting injection mold design. An effective cooling system improves production efficiency and reduces the risk of part deformation. KRMOLD car headlight injection molds typically employ a combination of vertical water pipes and baffle-type water wells to ensure an appropriate distance (15-25mm) between the cooling channels and the cavity surface. This design effectively avoids uneven heat distribution during production, improving injection cycle control and keeping it within 40 seconds.

5. Car Headlight Injection Mold Quality Inspection

Quality inspection is integral to the entire automotive lighting injection mold production process. During the trial molding stage, the dimensional accuracy of the cavity is checked using a coordinate measuring machine (CMM) to ensure tolerances are controlled within ±0.02mm. This minimizes product defects caused by car headlight injection mold issues.

5.1 Appearance and performance testing of injection molded parts

After automotive lighting injection mold completion, the produced injection molded parts undergo rigorous appearance inspection and optical performance testing. KRMOLD also conducts environmental simulation tests, such as continuous operation for 500 hours at 85°C and 85% humidity, to verify their weather resistance and sealing performance. Such testing ensures our products can function normally under various environmental conditions.

5.2 Application of AI vision inspection system

Furthermore, KRMOLD has introduced an AI vision inspection system that uses machine learning algorithms to identify minute defects on the surface of plastic parts, significantly reducing the missed inspection rate. Relying on advanced inspection technology, KRMOLD ensures that the quality of every car headlight injection mold meets the high standards of our customers.

5.3 Waterproof performance testing

For the waterproof performance of automotive lamps, all plastic parts must pass the IP67 rating test, meaning they can be immersed in 1 meter of water for 30 minutes without leakage. This stringent testing standard ensures the safety and reliability of the final product in use.

6. Customized Services for Car Headlight Injection Mold

KRMOLD can manufacture customized automotive lighting injection molds according to customer drawings and specific requirements. KRMOLD professional team will work closely with customers to ensure that car headlight injection mold design and manufacturing meet their actual needs. KRMOLD welcomes customers to visit factory to learn about production processes and equipment, or to contact KRMOLD online for more information and support.