KINGREAL UNIVERSAL IND., LTD

Phone

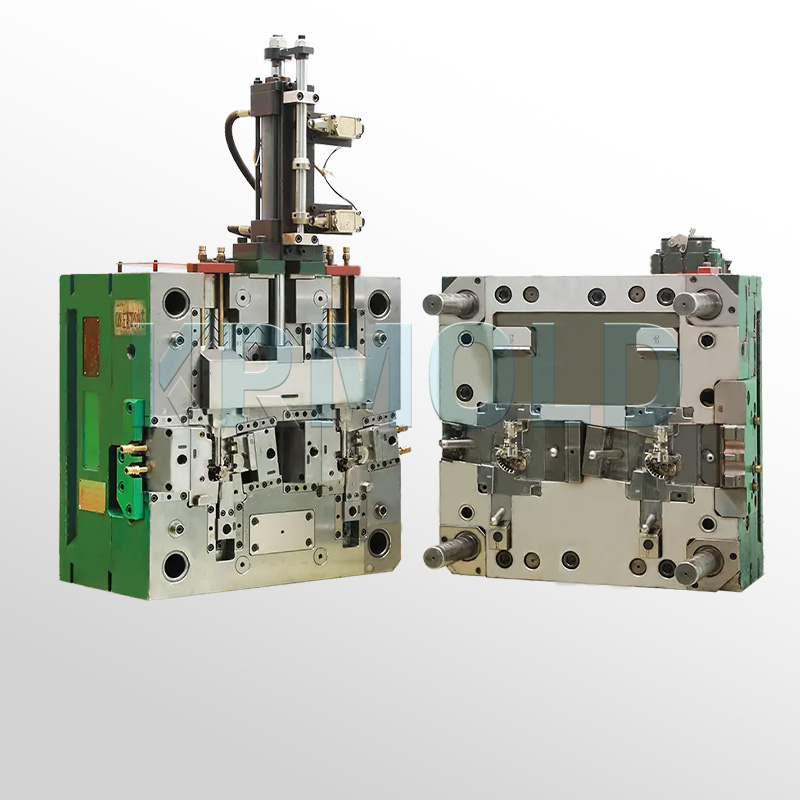

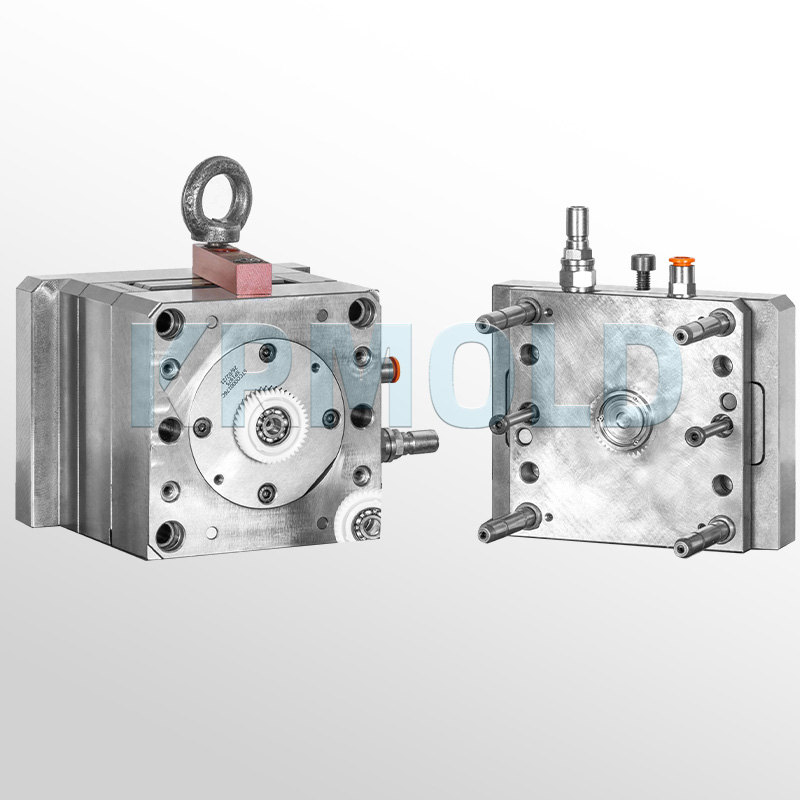

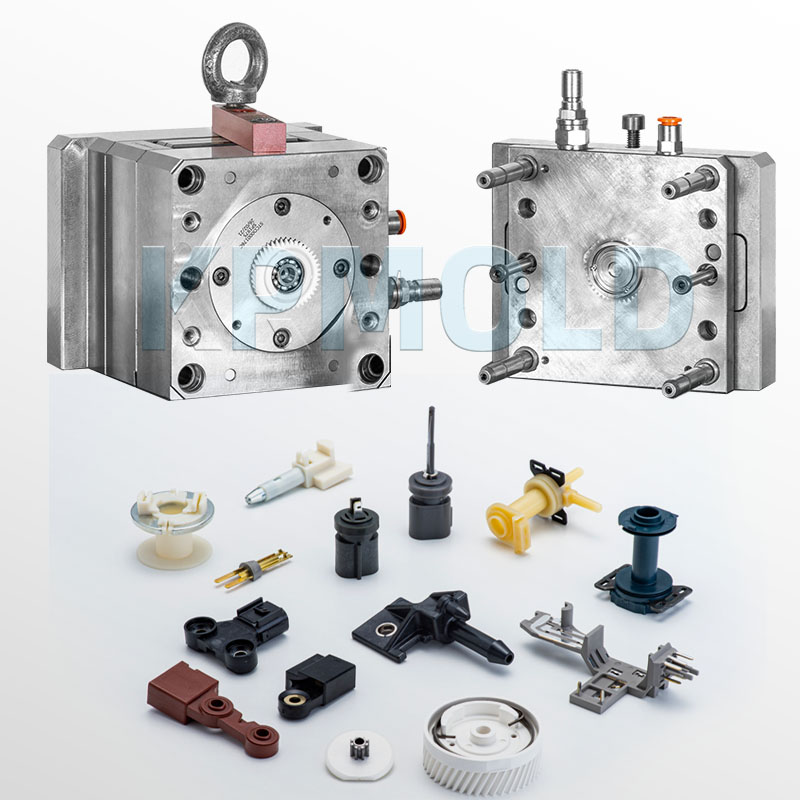

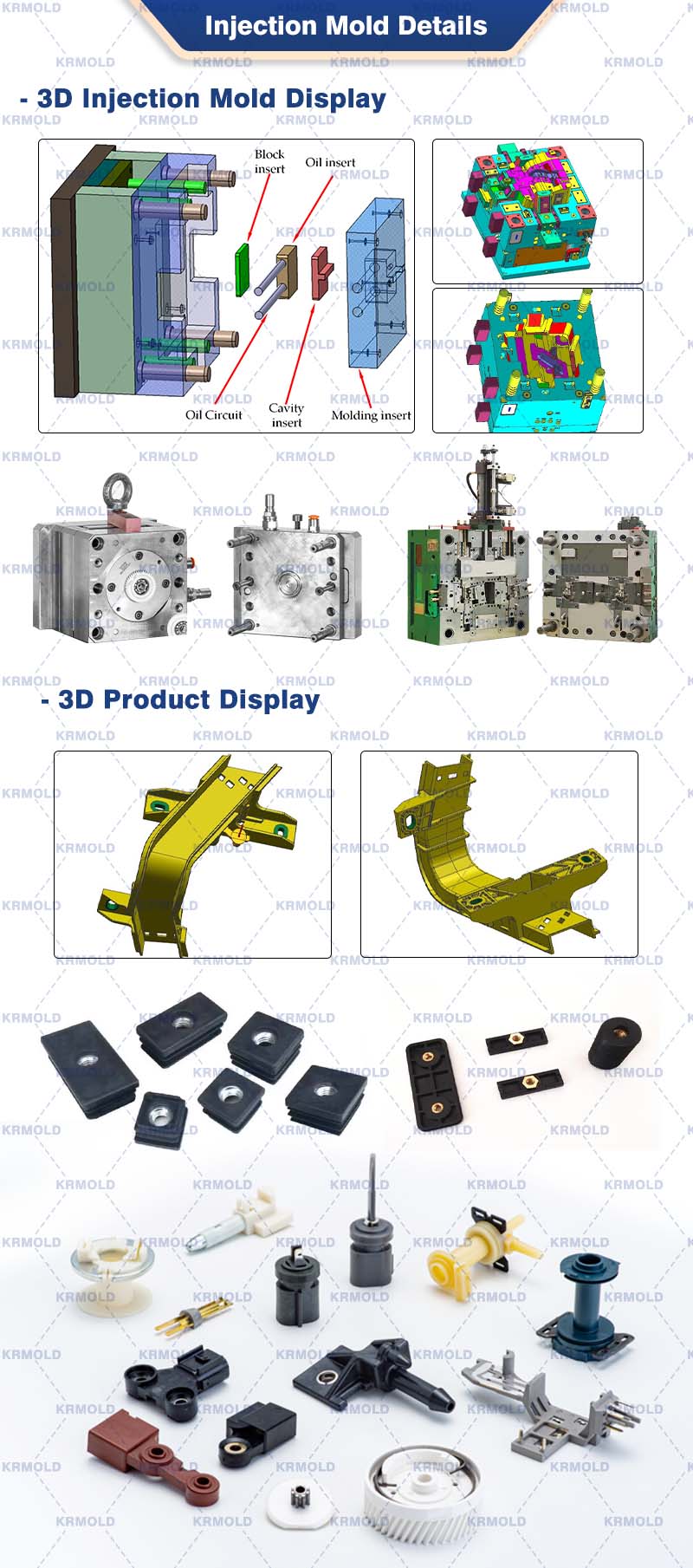

+86-13702855825A modern production technique,insert injection molding has come quite far in the plastics sector since its beginnings in the middle of the twentieth century. Many people choose this sophisticated technique for its capacity to produce complicated parts with improved durability, accuracy, and cost-effectiveness. Over the years, Insert Injection Molding has grown to be a crucial technique for a number of companies including automotive, medical, electrical, and consumer products. Fundamentally, insert molding is the combination of preformed elements—such metal or plastic inserts—with molded plastic parts. The insert is put into the mold cavity, and molten plastic is then injected around it, therefore achieving this. The finished product creates a perfect connection between the insert and the surrounding plastic material once the plastic hardens. This amalgamation not only makes assembly easier but also increases the component's strength and usefulness. Over conventional molding processes, insert injection molding has many benefits. Among these advantages are decreased assembly costs, decreased production time, increased design flexibility, and better part performance. It is anticipated to become more important in defining the future of the plastics manufacturing industry as more sectors embrace this cutting-edge molding technique. KRMOLD has gathered a short summary of insert molding in this post to assist you in grasp of this significant manufacturing method. Welcome to KRMOLD if you are interested in insert injection molds and want more parameter information. |  |

| 1 | What is Insert Molding? |

| 2 | Uses of Insert Molding |

| 3 | Stages in Insert Mold Making |

| 4 | Benefits of Insert Molding |

1.What is Insert Molding?

Insert injection molding is a plastic injection molding process that connects different parts into a whole. The final product is a permanently connected and fully encapsulated part. Because insert molding is a single process, it can improve production efficiency and reduce manufacturing costs, while producing parts with improved mechanical and functional properties.

2.Uses of Insert Molding

| Inserts can be placed into the mold and encapsulated during the molding process to create the finished product using insert injection molding. Common inserts include studs, contacts, and threads; they can be metal or plastic. Often used for components needing secondary processes to finish assembly, such bonding or welding, threaded inserts help. Insert molding is usually used for medical equipment needing sterilizing. The process can build a tight seal around the equipment, thus extremely appropriate for sterilization technology. Among insert molded items are screwdriver knobs, watertight cables, and medical syringes. |  |

3.Stages in Insert Mold Making

| The first step is the design of the component and mold; this starts the process. Choosing the right materials for the insert and plastic resin as well as creating a mold matching the insert and intended part geometry fall under this. The insert is produced or obtained in line with the design standards. The insert is then cleaned and ready for molding; frequently a surface treatment is added to boost the attachment of the insert to the plastic resin.

Preparations for the Insert Molding process: The mold is mounted on the injection molding machine. This entails choosing the proper temperature and pressure parameters for the chosen plastic resin.

Manual or robotic insertion of the prepared insert into the mold cavity guarantees appropriate alignment and orientation.

Until the plastic resin reaches a molten state, the injection molding machine warms it. High pressure injection of the molten plastic into the mold cavity around the insert guarantees the plastic fills the mold cavity and follows the required shape.

The molten plastic is allowed to cool and harden within the mold, bonding firmly with the insert.

Following the plastic solidifies, the mold is opened and the final piece is extracted. The quality of the piece is next reviewed to verify that the insert is correctly inserted, satisfies design criteria, and has general component integrity.

Following these procedures helps producers to create complex and high-quality pieces with improved durability, accuracy, and affordability using the Insert Molding method. |

4.Benefits of Insert Molding

(1)Insert injection molding streamlines several production stages into one process, therefore removing post-processing or further assembly requirements. This consolidation speeds time to market and shortens production cycles.

By enclosing the insert in the plastic substance, insert injection molding produces a tight connection between parts. Ultimately increasing the life of the finished product, this enhances resistance to wear, compression, vibration, and hence overall durability.

(2)Improved Part Performance: Insert molding allows functional components, such as electrical contacts or threaded fasteners, to be seamlessly integrated directly into the plastic part. This not only simplifies assembly, but also improves the overall performance of the finished product by reducing the likelihood of component failure or misalignment.

(3)Reduced Part Weight: By using lightweight plastic materials and minimizing the need for additional fasteners, insert molding can produce lighter parts. This is particularly beneficial in industries such as automotive and aerospace, where weight reduction is critical to improving fuel efficiency and reducing emissions.

(4)Improved Precision: The precision of insert molding allows for the creation of tight tolerances and complex geometries. This produces high-precision parts that meet stringent quality standards, ensuring reliable performance and customer satisfaction.