KINGREAL UNIVERSAL IND., LTD

Phone

+86-13702855825| 1 | What is ABS Injection Molding? |

| 2 | Process of ABS Plastic Injection Molding |

| 3 | Advantages of ABS Injection Molding |

| 4 | Applications of ABS Injection Molding |

| 5 | Why Choose KRMOLD? |

1. What is ABS Injection Molding?

| An industrial manufacturing method that shapes ABS resin into the wanted plastic shape is ABS injection molding. First the manufacturer installs the ABS injection mold on the injection molding machine, design and process it as per product needs. The ABS plastic pellets are then melted into a fluid in the injection molding machine, injected into the mold under high pressure, and cooled and solidified to create the molded components of the target plastic product. Mold manufacturing and ABS material molding are key stages of the entire process. The precise design and processing of the mold will affect the shape and precision of the product. The injection, holding pressure, cooling and other steps of material molding determine the quality and performance of the product. |  |

2. Process of ABS Plastic Injection Molding

1

Pretreatment of materials

ABS plastic must be thoroughly dried before it may be used in manufacturing. For 24 hours, the drying temperature varies from 8085 degrees Celsius. A drying hopper at 80°C offers yet another technique. The last approach, though, only holds twelve hours.

2

Injection molding machine calibration

Following material processing, the ABS plastic injection molding equipment must be ready for operation. This calls for establishing parameters including injection pressure, clamp force, and compression ratio. Typical values for these factors include: compression ratio more than 2; clamping force between 4700 and 62000t/m²; and injection pressure above 1500 bar.

3

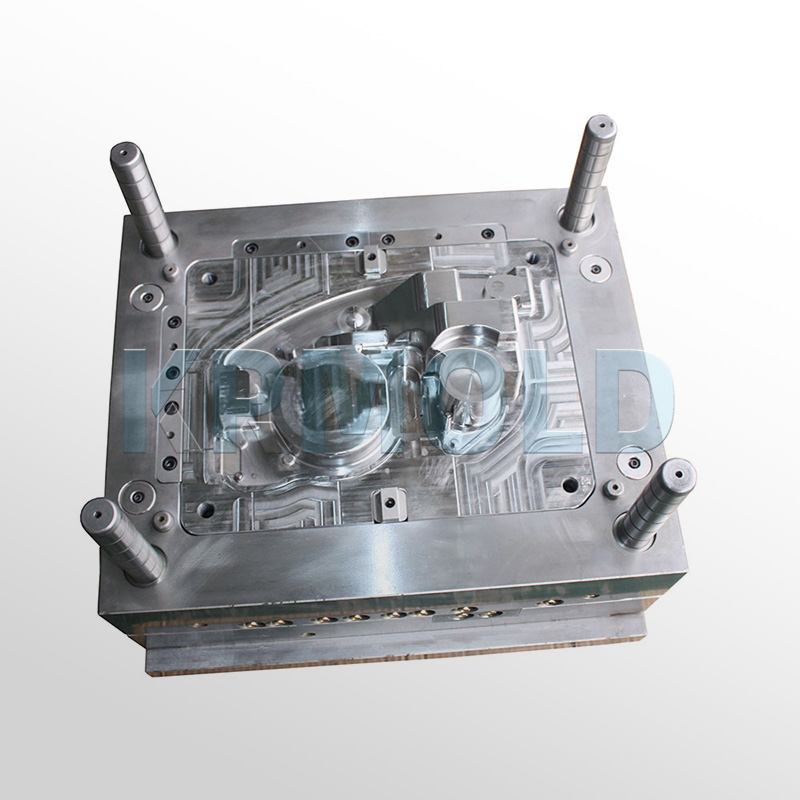

Gate arrangement and mold

ABS products are molded with the aid of the mold. Designing the mold and gate is therefore quite crucial for the whole ABS plastic injection molding operation. Usually, the ABS mold is between 0.025 and 0.05 mm thick; the gate length is under 1 mm. Furthermore, the diameter of the channel via which the molten ABS flows is set to 3 mm, whereas the width of the vent hole is 4–6 mm. Finally, the mold temperature is always held between 60 and 65 degrees Celsius.

4

Injection temperature

The ABS quality/grade utilized will influence the injection temperature applied for a particular ABS plastic injection molding method. Common ABS plastic injection molding grades and ideal ABS injection molding temperatures follow:

Flame retardant grade: 200 – 240°C; ideal temperature is 220°C – 230°C;

Electroplating degree: 250–275°C, ideal temperature is 270°C;

Reinforcement grade: 230 degrees Celsius to 270 degrees Celsius;

High impact grade: 220°C – 260°C, optimal temperature is 250°C;

Heat resistant grade: 240°C – 280°C; best temperature is 265°C – 270°C.

5

ABS injection molding velocity

The grade of ABS plastic and the demands of the completed product define the ABS plastic injection molding speed. For instance, flame retardant ABS plastic requires just slower ABS injection molding speeds. Additionally, goods needing perfect surface treatment may call for highspeed ABS injection molding.

6

Stay time

Dwell time is the period plastic pellets must travel from the injection mold barrel to the injection mold. Typically, the dwell time for ABS plastic at temperatures under 265°C is 56 minutes. For flame retardant grade ABS plastic, on the other hand, the dwell time is shorter and the temperature is lower.

7

Back pressure

It is recommended to keep the back pressure as low as possible during ABS plastic injection molding to prevent wear. The acceptable pressure is usually around 5 bar.

8

Cleaning

Some grades of ABS tend to stick to the mold screw after removing the part. Therefore, the best cleaning method is to wait for the residue to be ground off and then thoroughly clean the ABS injection molding machine compartment with polystyrene.

3. Advantages of ABS Injection Molding

(1)High molding accuracy: Good dimensional stability: After ABS injection molding, the dimensional change of ABS material is relatively small, which can effectively maintain the designed size. This is essential for manufacturing parts with high dimensional accuracy requirements, such as small plastic brackets in the engine compartment of a car. Its precise size ensures good fit with other parts.

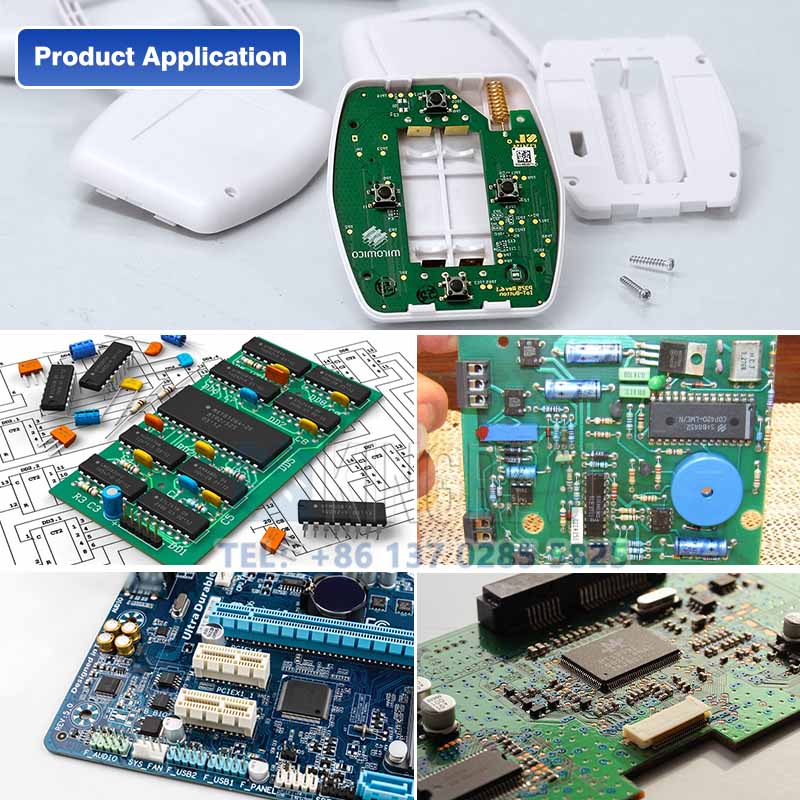

High Replication Accuracy: The ABS injection molding process can accurately replicate the shape and details of the mold. The products produced have high consistency and repeatability, even for parts with complex shapes and fine structures. For example, ABS injection molding for electronics ensures that the size, shape and feel of tiny buttons in consumer electronics are highly consistent. |  |

(2)Manufacturing Complex Shapes: High Design Freedom The ABS injection molding process can form a variety of complex shapes with minimal restrictions on shapes. Designers can give full play to their creativity and design products with unique appearance and structure. For example, custom ABS plastic injection molding can easily produce household items such as creative vases and lamps with unique shapes and smooth designs.

Integrate Multifunctional Parts: The process can integrate different functional parts into one ABS molded part, thereby reducing the number of parts and assembly steps. This improves production efficiency and product reliability. For example, in ABS injection molding for automotive parts, various control buttons and display mounting locations can be integrated into one molded part. |  |

4. Applications of ABS Injection Molding

Automobiles and Electric Vehicles: Dashboard Trim Automotive HVAC Systems Under-hood Components Interiors Airbag System Housings Automotive Lighting Systems |  |

Wireless Speaker Housings Smart Thermostat Components Laptop Housings Game Controller Housings Connectors for Consumer Electronics |  |

Portable Medical Devices Diagnostic Equipment Housings Laboratory Instruments Pharmaceutical Equipment Medical Sensor Housings |  |

Kitchen Gadget Boxes Blender Bases Microwave Door Panels Vacuum Cleaner Housings Robotic Cleaners |  |

5.Why Choose KRMOLD?

(1)Advanced Equipment and Personnel KRMOLD has a professional mold design team and sophisticated mold manufacturing equipment. (2)Rich Production and Manufacturing Experience KRMOLD has a comprehensive understanding of the characteristics of ABS plastics, has mastered a variety of injection molding processes, and can design according to customer requirements. Able to optimize the process. It can provide a variety of surface treatment services and can perform quality control. (3)Scientific Quality Control Measures KRMOLD can conduct raw material inspection, process quality control and finished product quality inspection. They have obtained relevant quality certifications, can meet the standards of relevant industries, and can meet the customized quality requirements of specific customers. |  |