KINGREAL UNIVERSAL IND., LTD

Phone

+86-13702855825| 1 | Design Characteristics of Auto Engine Cover Injection Mold |

| 2 | Advantages of Auto Engine Cover Injection Mold |

| 3 | Main Points of Car Engine Cover Injection Mold |

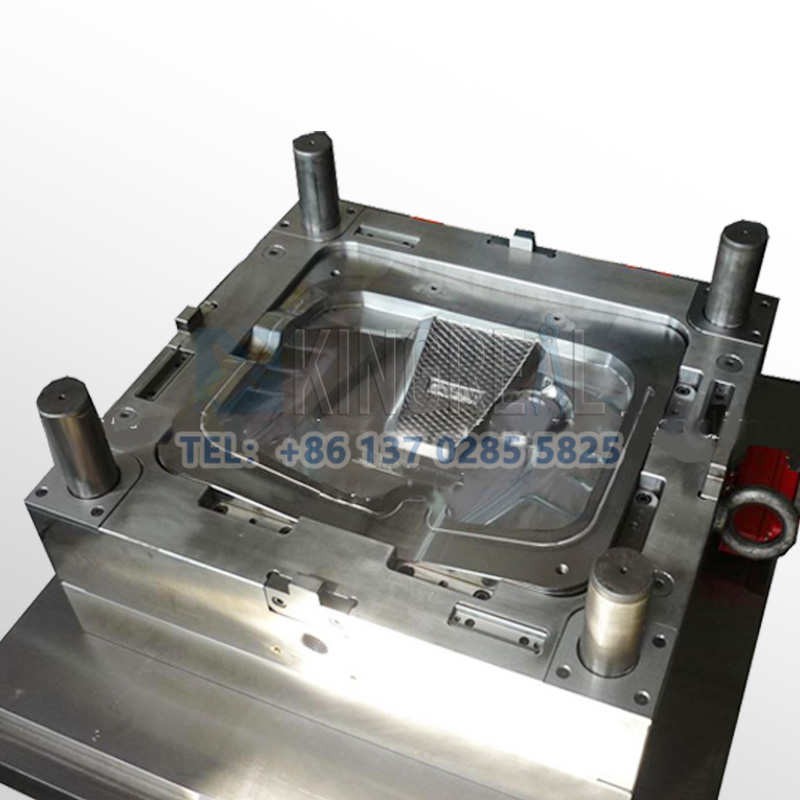

Auto engine cover injection mold can produce high-precision car engine cover, which can be applied to different styles, types and sizes of automobiles. Due to the rigorous process of car engine cover injection mold design, manufacture and application, beginners need to master the core points systematically in order to carry out production and application smoothly. This article will introduce the knowledge about the design of auto engine cover injection mold in detail.

1. Design Characteristics of Auto Engine Cover Injection Mold

(1) Structural design for car engine cover injection mold

The gating system of the auto engine cover injection mold

The car engine cover is a large thin-walled part. In order to avoid uneven filling, the auto engine cover injection mold generally adopts a hot runner system, with a 10-point gating scheme and sequential valve control technology. By adjusting the feeding time sequence and speed of each gate, the uniform flow and full filling of plastic raw materials in the cavity are ensured, and the consistent wall thickness and appearance quality of the auto engine cover are guaranteed.

Metal insert positioning mechanism

Metal inserts (such as reinforcing ribs) are often assembled on the auto engine cover, and the auto engine cover injection mold will be designed with a special positioning structure of "H-block+hook+floating block". The structure can accurately position and firmly clamp the insert, and can also assist the smooth separation of the insert and the car engine cover injection mold, avoid mold sticking, and improve production efficiency and qualified rate.

Mold cooling system

The uniformity of auto engine cover injection mold temperature directly affects the deformation rate of car engine cover, and the mold cooling system adopts independent loop design. Configure independent cooling waterways for different areas, accurately control the auto engine cover injection mold temperature, ensure the uniform temperature of plastic raw materials when they are cooled and solidified, minimize the risk of product deformation, and ensure the dimensional accuracy.

(2) Material selection of auto engine cover injection molds

The selection of steel for car engine cover injection mold needs to match the working conditions and product requirements: P20 pre-hardened steel (pre-hardness 30-35HRC, good machinability and toughness) is selected for routine requirements; 718H steel (high hardness and excellent polishing after heat treatment) should be selected to improve the surface smoothness and wear resistance; NAK80 steel is selected when the hood needs mirror appearance (mirror effect can be achieved without complicated polishing).

(3) Process optimization of auto engine cover injection mold

Defect prediction and parameter optimization

Before formal production, analyze the flow and filling process of raw materials in the cavity with CAE simulation technology, and predict weld marks, shrinkage marks and other defects. According to the simulation results, adjust the gate position and pressure maintaining parameters, optimize the molding scheme, reduce the number of car engine cover injection mold trials, reduce the cost and shorten the cycle.

High-precision machining

The die is a large-scale equipment, and it is difficult to machine some deep cavity structures (such as the cavity depth of A plate is 710mm), so it is necessary to use a 5-axis machine tool to realize multi-dimensional precision cutting; Customize non-standard tools for special structures to ensure the machining accuracy meets the design standards and ensure the molding quality of products.

2.Advantages of Auto Engine Cover Injection Mold

(1) Low-cost car engine cover injection mold: Auto engine cover injection mold often adopt single-cavity design, which can be adapted to small injection molding machines, without the need for enterprises to invest in large-scale equipment, thus greatly reducing procurement costs; And the small injection molding machine has lower energy consumption, can reduce the energy consumption of production, and is suitable for small and medium-sized enterprises or small batch production.

(2) Environmentally-friendly auto engine cover injection mold: Some car engine cover injection molds adopt rotary injection molding mechanism, and are injection molded twice (such as engine cover with anti-skid pad base), and the generated wastes (such as leftover materials of anti-skid pad base) can be recycled, thus reducing plastic pollution and improving the utilization rate of raw materials.

(3) High-precision car engine cover injection mold: Through optimized design and precision machining, the auto engine cover injection mold tolerance is strictly controlled within 0.05 mm ~ 0.1 mm, ensuring that the dimensional accuracy of the produced cover fully meets the assembly requirements of automobile parts.

3.Main Points of Car Engine Cover Injection Mold

(1) Car engine cover injection mold process parameters control

Melt temperature of the car engine cover injection mold

Set according to the characteristics of raw materials, such as ABS material, which should be controlled at 220-250℃. If the temperature is too low, it will easily lead to insufficient filling, while if it is too high, it may decompose the raw materials, so it needs to be accurately set and monitored.

Injection pressure of car engine cover injection mold

Usually controlled at 80-120MPa, which needs to be adjusted according to mold structure and raw material characteristics. Insufficient pressure will lead to insufficient filling, while too high pressure will easily increase die loss or flash, so it is necessary to find the optimal value through gradual debugging.

Car engine cover injection mold cooling time

Generally 10-300 seconds, which needs to be adjusted according to product thickness, raw material characteristics and mold temperature. Too short time will easily lead to product deformation, too long will reduce production efficiency, so it is necessary to balance quality and efficiency.

(2) Preventive measures for defects of car engine cover injection mold

Short shot processing

Short shot shows that the product is short of material, so it is necessary to check the gate size first (if it is too small, it will expand), and then adjust the injection speed (if it is too slow, it will increase) to ensure that the raw materials are fully filled within the specified time.

Shrinking treatment

Shrinking marks mostly appear in the uneven wall thickness, so it is necessary to optimize the packing parameters, extend the packing time to replenish raw materials, adjust the packing pressure to match the cavity pressure, and suppress the sag.

(3) Key points of car engine cover injection mold maintenance

Hot runner nozzle cleaning

After long-term use, the nozzle is easy to remain carbonized raw materials, so it needs to be cleaned regularly to avoid affecting product quality or blocking the nozzle, so as to ensure smooth hot runner system.

Die life management

Under normal working conditions, the die life is 300,000-500,000 molding cycles, so it is necessary to establish a usage account to record the usage times and maintenance conditions, and prepare spare parts or repair plans in advance when approaching the life to avoid production interruption.