KINGREAL UNIVERSAL IND., LTD

Phone

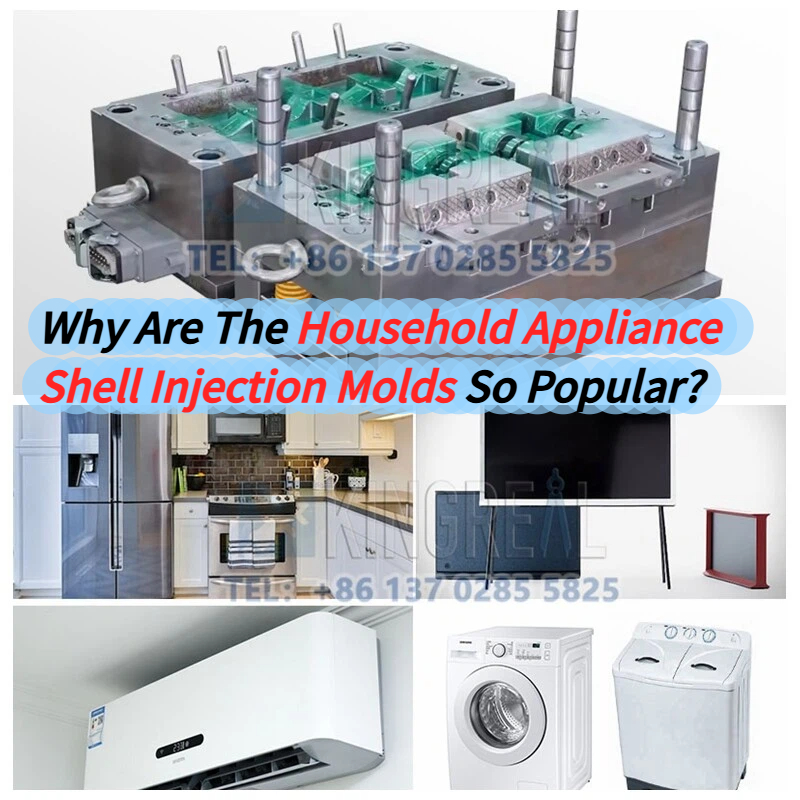

+86-13702855825In the current home appliance market, household appliance shell injection molds are indispensable tools in the manufacturing process. These home appliance shell injection molds are not just instruments to bring the exterior to life but are also essential components in guaranteeing product performance and durability. Research done by the industry shows that home appliance shell injection molds are mostly employed in goods including washing machines, refrigerators, air conditioners, microwave ovens, and televisions. The market for home appliance shell injection molds is always increasing as the home appliance sector is evolving toward intelligence and environmental friendliness. These household appliance shell injection molds are slowly showing trends including automation and digitalization, accuracy and miniaturization, environmental protection and recyclability, and personalized customization as a result of these industry developments. Home devices have greatly transformed our life, introducing several comforts. Electrical devices have become less expensive, more durable, and more adaptable thanks to home appliance shell injection mold. The functionality and aesthetics of the products largely depend on the injection-molded components, making household appliance shell injection molds widely popular. |  |

1.Common Applications of Home Appliance Shell Injection Molds

1.1 Home appliance shell injection mold for washing machine

To withstand the extreme heat and humidity inside the appliance, household appliance shell injection molds have to be strong, long-lasting, and waterproof. With accurate injection molding methods, producers may guarantee the stability and safety of the casing over time, so improving the product's longevity.

1.2 Home appliance shell injection mold for air conditioner

Air conditioner casing units require precise and high-quality plastic components, and household appliance shell injection molds play a crucial role in this area. Through home appliance shell injection mold, manufacturers can produce components with complex geometric shapes, high heat resistance, and sufficient ventilation and cooling functions, thereby improving the performance and efficiency of air conditioners.

1.3 Home appliance shell injection mold for vacuum cleaner

The lightweight but strong household appliance shell injection molds employed in vacuum cleaners also give aesthetics and practicality top importance. Keeping great looks and performance, these components have to survive constant use, therefore home appliance shell injection molds are a vital component of vacuum cleaner manufacturing.

1.4 Home appliance shell injection mold for small appliance

Small appliances like hair dryers, irons, and electric kettles also use plastic parts made from home appliance shell injection mold. High requirements for electrical safety, heat resistance, and strength must be satisfied by these parts to guarantee general product performance and user safety.

2.The Important Role of Home Appliance Shell Injection Mold Design

The design of household appliance shell injection molds is extremely important since it affects the look, usability, and durability of the item. To guarantee the product satisfies the specified quality and functionality, the design process has to take into account the technical capacity of the molding approach and performance needs.

2.1

Home appliance shell injection mold and part design

Ensuring a flawless and effective process is crucial during the design phase. Designers have to pay close attention to the geometry of the components and household appliance shell injection molds, wall thickness, drafts angles, and material choice.

These elements have a direct impact on the cooling process and the way the molten plastic fills the mold, therefore impacting the structural integrity of the component. Deliberate design lowers manufacturing costs and lowers later secondary operations.

2.2

Collaboration between designers and engineers

Good collaboration between product designers and home appliance shell injection mold engineers is essential. Designers focus on creating efficient and visually appealing components, while engineers ensure that these designs are feasible for injection molding manufacturing.

Through close collaboration, designers can modify the ergonomic shape of components based on user experience, while engineers can adjust material distribution within the design.

2.3

Enabling innovative designs through injection molding

The precision and flexibility of household appliance shell injection molds enable many innovative designs that are difficult to achieve with traditional manufacturing processes. For example, multi-material components manufactured through overmolding can enhance product functionality and comfort. Thin-wall molding techniques can also produce lightweight yet strong components, aligning with the increasing demand for streamlined designs in modern home appliances.

Parts with complex internal geometries can be efficiently manufactured with the help of home appliance shell injection molds, whereas in the past, other methods might only achieve partial functionality. Components with built-in snap-fit connectors reduce the reliance on adhesives and screws during assembly, improving overall structural stability.

2.4

Material selection and quality control

Material selection is crucial during the design process. The plastic materials used in household appliance shell injection molds must not only be durable to ensure the long-term use of the appliances but also possess different textures and surface effects to achieve the designer's desired aesthetic. Simultaneously, the quality of the home appliance shell injection mold is fundamental to guaranteeing part performance. Manufacturers rely on a variety of rigorous procedures to maintain part quality, minimize errors, and improve overall performance.

Design for Manufacturability (DFM) and tolerance analysis are crucial for ensuring quality control in the early stages. These approaches help manufacturers identify potential problems before full-scale production, optimize part design, and ensure the accuracy of dimensions, shapes, and fits.

Household appliance shell injection molds offer extremely high precision, allowing for the creation of complex and intricate shapes. High-pressure injection enables molten plastic to quickly fill every corner of the home appliance shell injection mold, ensuring that products meet customer demands in a short time with high production volume. The reusability of the household appliance shell injection molds allows for long production runs, increasing production efficiency and reducing costs.

For more information about home appliance shell injection molds, please contact KRMOLD! KRMOLD will be happy to assist you in finding the most suitable household appliance shell injection mold solution.