KINGREAL UNIVERSAL IND., LTD

Phone

+86-13702855825In the vast manufacturing field, plastic injection molding occupies a pivotal position. The process of plastic injection molding covers the transformation of raw materials into products with specific shapes, structures and functions. As a specific molding technology, plastic injection molding produces a variety of precise and complex plastic products by heating plastic particles to a molten state, injecting them into the mold cavity under high pressure, and solidifying them after cooling. In this article, KRMOLD will discuss in depth the relevant knowledge and applications of plastic injection molds and injection molding. |  |

| 1 | Overview of Plastic Injection Molds |

| 2 | Important Parts of Plastic Injection Molds |

| 3 | Application of Plastic Injection Molding |

| 4 | Advantages of Plastic Injection Molding |

1.Overview of Plastic Injection Molds

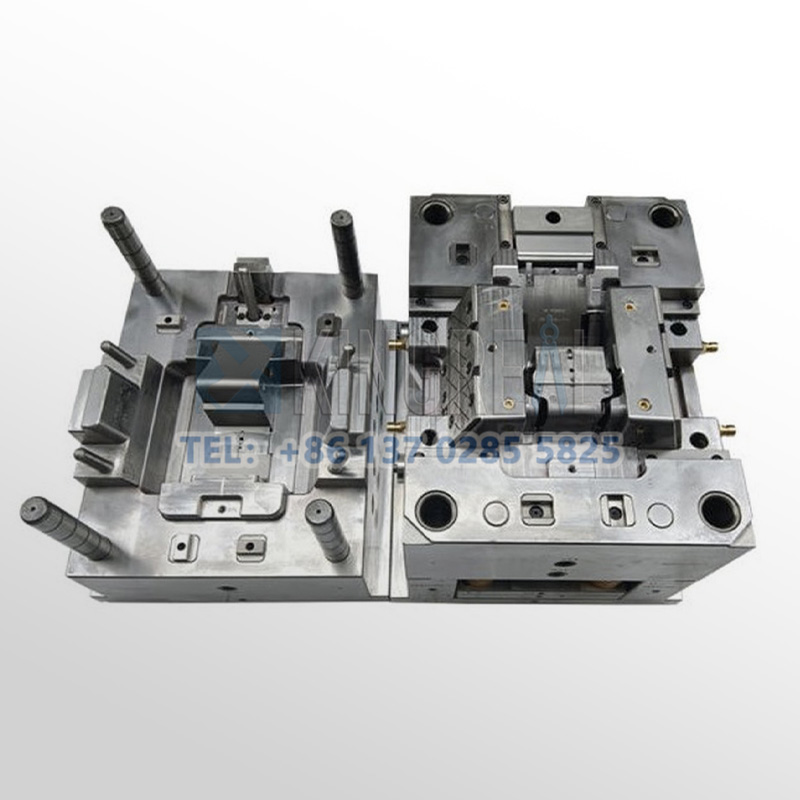

Plastic injection molds are key tools for realizing the injection molding process, usually consisting of a movable mold and a fixed mold. The movable mold is fixed to the moving template of the injection molding machine, while the fixed mold is installed on the fixed template. They form a closed structure during the plastic injection molding process to construct a pouring system and a cavity. When the plastic injection molds is separated, the molded plastic product can be taken out smoothly.

2.Important Parts of Plastic Injection Molds

(1)Molding parts

Core: responsible for the inner surface molding of plastic products.

Die: forms the outer surface shape of the product, which may be composed of multiple pieces or processed as a whole.

(2)Gating system (runner system)

The gating system is the channel that guides the plastic melt from the injection molding machine nozzle to the cavity, mainly including the main channel, branch channel, gate and cold material hole. A well-designed gating system is the key to ensuring the quality of the finished product and improving production efficiency.

(3)Guide components

The main function of the guide components is to ensure the accurate alignment of the movable mold and the fixed mold during mold closing, and to avoid skew during the product ejection process. Guide pins and guide sleeves are usually used.

(4)Ejection mechanism

During the plastic injection molds opening process, the ejection mechanism is responsible for smoothly ejecting the plastic parts and the condensate in the runner.

(5)Thermostatic system

The thermostatic system ensures that the mold temperature meets the injection process requirements. The common method is to open a cooling water channel in the plastic injection molds, use circulating cooling water to take away the heat, or install electric heating elements inside and around the plastic injection molds.

(6)Venting groove

The function of the exhaust groove is to fully remove the gas in the injection molding process. Usually, an exhaust groove is opened at the parting surface, or a small gap is used for exhaust.

(7)Side core pulling mechanism

For plastic parts with side concave or side hole, a side core pulling mechanism needs to be set in the plastic injection molds to facilitate lateral parting before ejection.

3.Application of Plastic Injection Molding

Injection molding is extensively utilized in the car industry to create interior components like dashboards, door panels, seats, etc.; exterior decorative items like bumpers, lampshades, car logos, etc.; and functional elements like water tanks, pipes, fuel tanks, etc. Plastic injection molding is also very important in the use of light materials as new energy vehicles quickly develop, therefore assisting automakers to lower vehicle weight and raise energy efficiency.

Plastic injection molding is extensively employed in the household appliance sector to create the outer shell and inner parts of appliances including televisions, refrigerators, washing machines, and air conditioners. These polymer materials have excellent insulation characteristics in addition to their gorgeous look.

The medical device sector has extremely high standards for product quality and sanitation. Along with medical device housings, disposable medical items (syringes, infusion sets, blood collecting instruments, etc.) use plastic injection molding technology extensively. These items need to adhere to tight safety and hygiene criteria; hence, injection molding technology can offer high-precision, high-cleanness manufacturing solutions.

(4) Electronic device industry

Plastic injection molding is quite important in the manufacturing of electronic product casings including mobile phones, computer accessories, keyboards, mice, and MP3 players in the electronic device industry. These goods need great structural strength as well as great looks. Injection molding technology offers outstanding electromagnetic shielding and insulation performance, therefore memenuhi these criteria.

Plastic injection molding technology helps the packaging sector as well, and it is commonly employed to make several kinds of packaging containers including food packaging boxes, bottle caps, and bottles. Plastic injection molding technology creates, for instance, plastic bottles for drinks and dairy goods as well as bottle caps for pharmaceuticals and cosmetics. Plastic injection molding techniques may offer high-precision, low-cost production solutions for food safety, moisture resistance, and impact resistance in these packaging items.

4.Advantages of Plastic Injection Molding

High precision: By means of careful plastic injection molds design and processing, injection molding enables creation of plastic items with very high precision.

Flexible: Different plastics can be chosen for manufacture depending on requirements; injection molding technique is suitable for a range of plastic materials.

Plastic injection molding's high rate of raw material use helps to cut waste of raw materials.

Plastic injection molding guarantees stable quality and consistent shape and size for every product.