KINGREAL UNIVERSAL IND., LTD

Phone

+86-13702855825| 1 | Definition and basic principle of radiator grille molding industry |

| 2 | Main market of radiator grille mold |

| 3 | Technical development status of radiator grille molding industry |

| 4 | Main development trends of radiator grille molding industry |

| 5 | Global market competition pattern of grille housing plastic mold |

1. Definition and basic principle of radiator grille molding industry

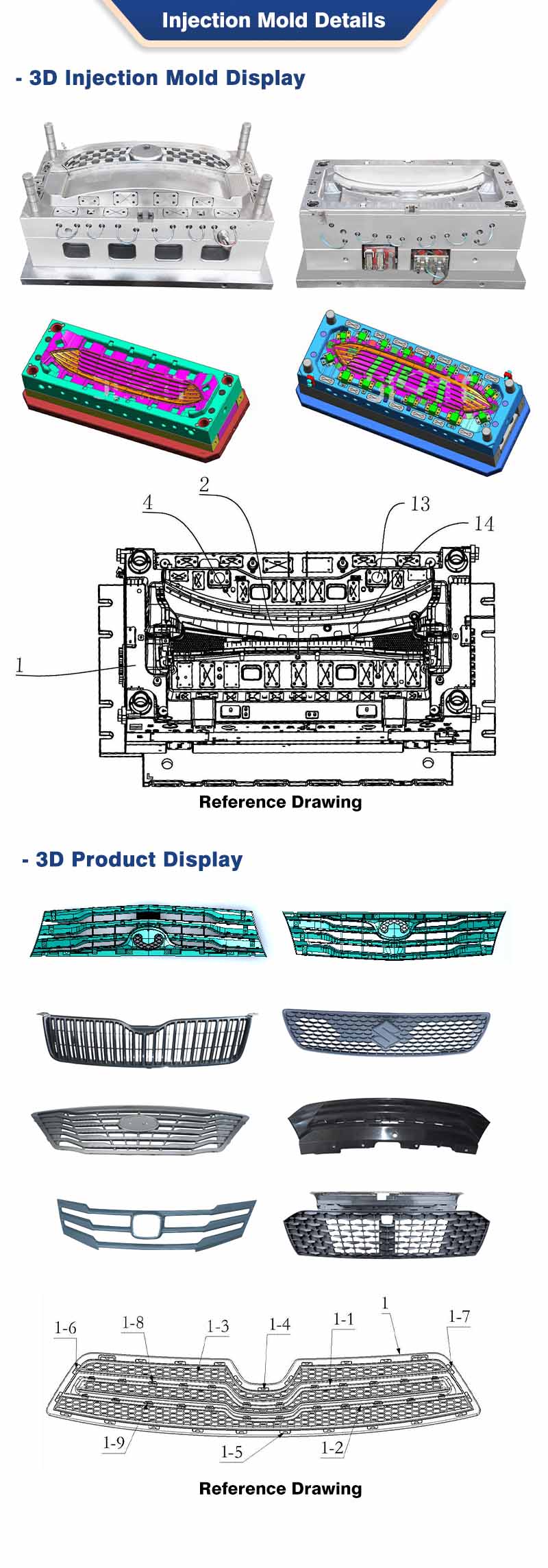

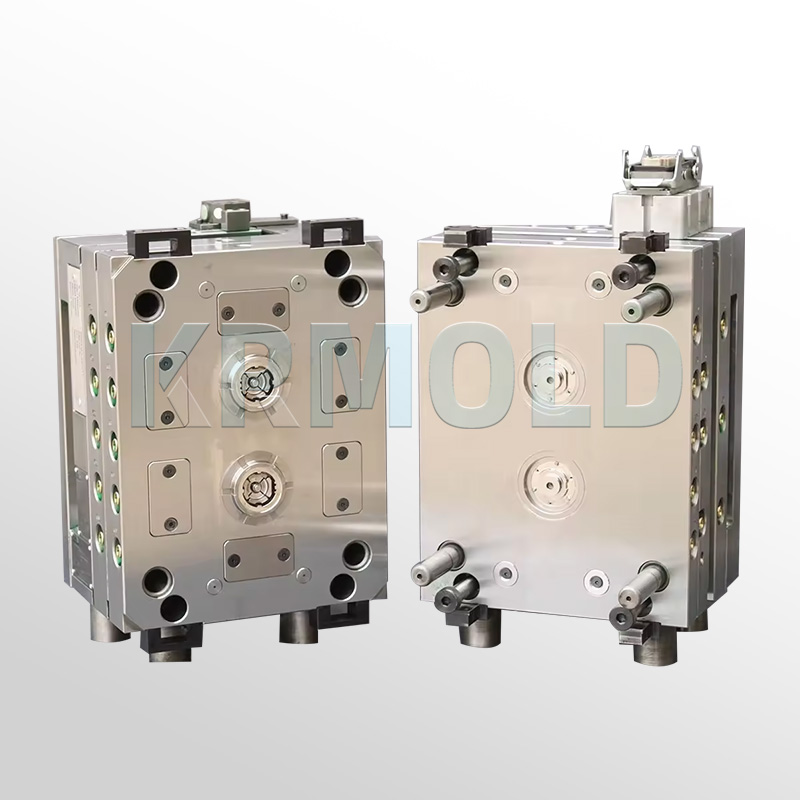

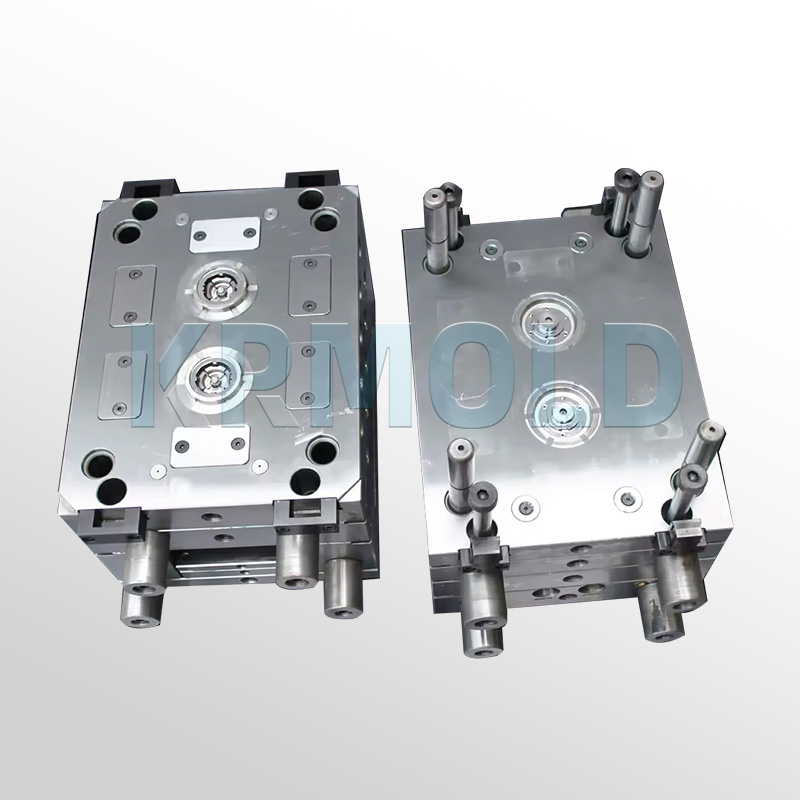

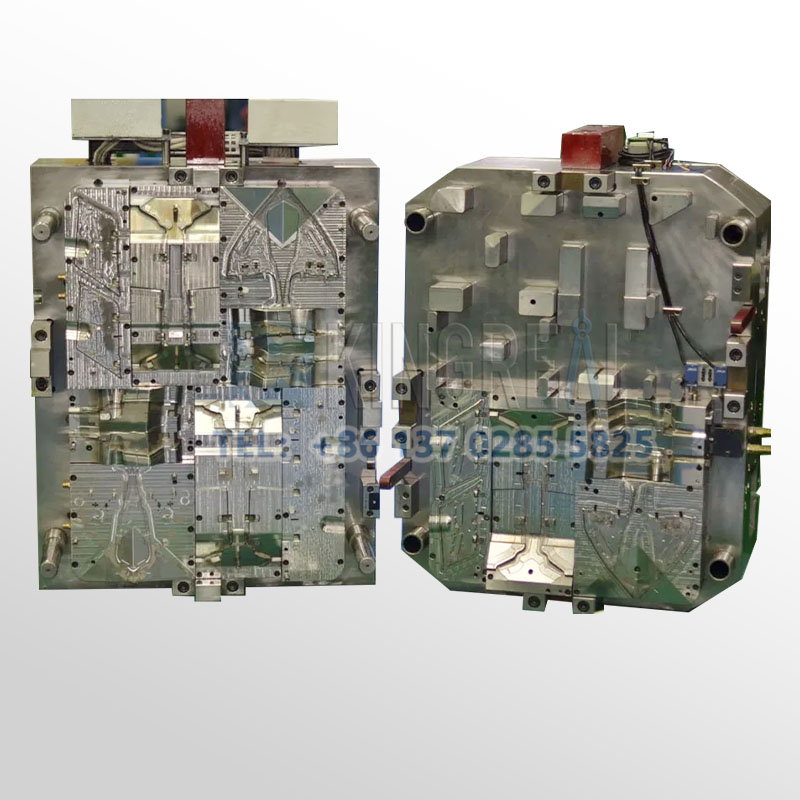

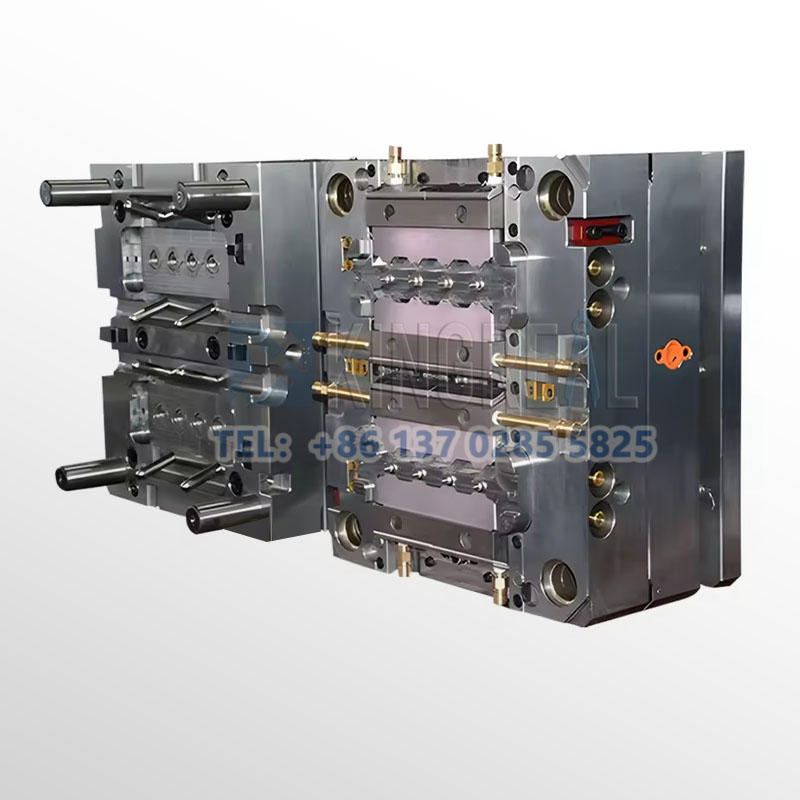

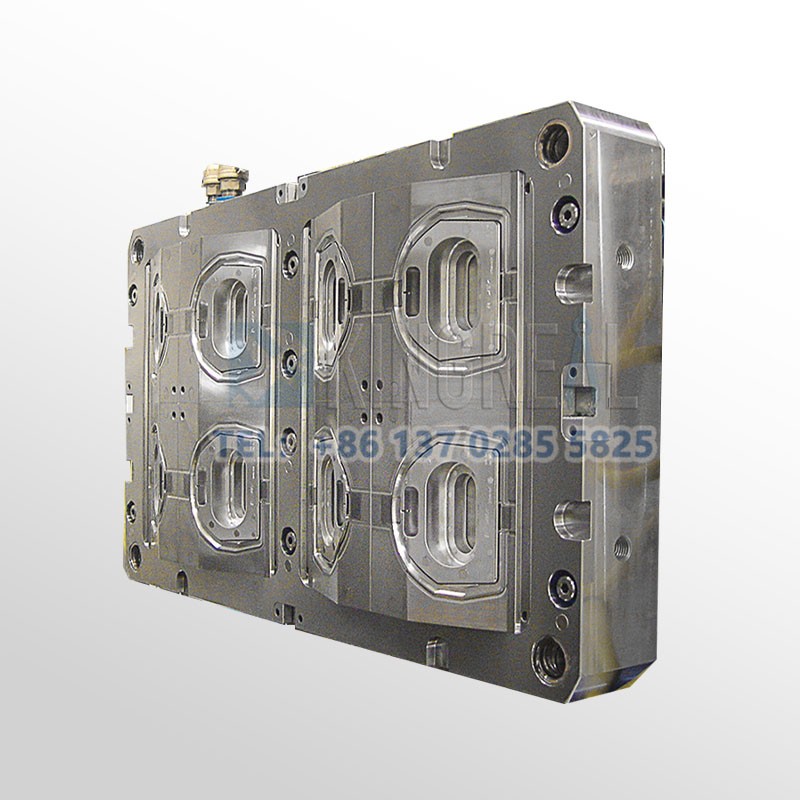

Grille housing plastic molding industry refers to the industry that manufactures plastic products through bumper integrated grill molding process, which usually involves heating thermoplastic particles to a molten state, then injecting them into radiator grille mold through bumper integrated grill molding machines, and cooling and curing them to obtain the required plastic products. Grille housing plastic molding is an efficient and accurate manufacturing process, which is widely used in many industries such as electronics, electrical appliances, automobiles, medical care, home and so on.

With the continuous innovation of technology, bumper integrated grill molding technology has gradually developed into high-end technologies including multi-layer grille housing plastic molding, precision radiator grille molding and micro-radiator grille molding.

2.Main market of radiator grille mold

(1) China: an important market for radiator grille mold sales.

As the center of global manufacturing industry, China has a huge demand for bumper integrated grill molds. Many domestic and foreign enterprises have turned their eyes to the China market to seek opportunities for cooperation and development. China's grille housing plastic mold industry has made remarkable progress in scale and technical level, providing high-quality products and services for domestic and foreign customers.

(2) United States: technological innovation leads market growth

As one of the cradles of bumper integrated grill mold technology, the market demand in the United States is equally strong. American radiator grille mold enterprises pay attention to technological innovation and quality improvement, and constantly introduce competitive new products. At the same time, the American market environment also provides good development opportunities for grille housing plastic mold enterprises.

(3) Europe: stable market and diversified demand

The grille housing plastic mold market in Europe is relatively stable and the demand is diversified. European countries have strict requirements on product quality and environmental protection standards, which provides a broader development space for bumper integrated grill mold enterprises. At the same time, the development of automobile, household appliances and other manufacturing industries in Europe has also provided continuous impetus for the grille housing plastic mold market.

In addition to the above major markets, the bumper integrated grill mold market in Southeast Asia, India and other regions is also gradually rising. The manufacturing industry in these areas is developing rapidly, and the demand for radiator grille molds is increasing. In the future, with the further integration of the global economy and the transformation and upgrading of the manufacturing industry, the bumper integrated grill mold market is expected to show a broader development prospect.

3.Technical development status of radiator grille molding industry

(1) Leading role of advanced grille housing plastic molding technology

The technology of bumper integrated grill molding industry is constantly innovating, and it has developed from traditional mechanized production to intelligent and precise direction. At present, the common advanced technologies in grille housing plastic molding process include:

Micro-injection technology: This technology can produce extremely small and complex plastic parts, which are mainly used in the manufacture of medical devices, electronic products and automobile precision parts.

Multicolor/multi-material radiator grille molding technology: This technology can inject different colors or different kinds of materials into the moldgrille housing plastic mold in the same injection cycle, thus producing plastic products with complex structures and different material combinations, which are widely used in the fields of automobiles, household appliances and consumer goods.

Intelligent grille housing plastic mold: by introducing digital control and sensing technology, the design and manufacture of grille housing plastic mold are more precise, which can effectively improve production efficiency and product precision.

(2) Combination of 3D printing and radiator grille molding technology

With the maturity of 3D printing technology, the bumper integrated grill molding industry began to try to combine 3D printing technology with traditional grille housing plastic molding technology to form a more flexible and efficient production mode. For example, 3D printing is used to make grille housing plastic mold prototypes or parts in small batches, thus shortening the product development cycle and reducing the bumper integrated grill mold manufacturing cost. Grille housing plastic molding enterprises have gradually achieved initial results in the application of 3D printing technology, especially in precision manufacturing and personalized customization, showing a strong competitive advantage.

(3) Intelligent management in the process of radiator grille molding production

Grille housing plastic molding industry is moving towards intelligent production mode. Many bumper integrated grill molding enterprises have begun to adopt technologies such as Internet of Things, artificial intelligence and big data analysis to comprehensively monitor and optimize the production process. For example, through real-time data analysis, the working state of radiator grille molding machine can be monitored, equipment failures can be predicted, and losses caused by downtime can be avoided. In addition, the introduction of intelligent production line makes Enterprises can improve production efficiency and reduce labor costs through automation.

4. Main development trends of radiator grille molding industry

In recent years, the main development trends of the global radiator grille molding industry include:

Intelligence and automation: With the concept of Industry 4.0 and intelligent manufacturing put forward, the bumper integrated grill molding industry is gradually realizing digitalization, automation and intelligence. Through the introduction of intelligent equipment, the production efficiency has been greatly improved and the product quality has become more stable.

Green environmental protection: sustainable development has become an important topic of concern in the global radiator grille molding industry. Many bumper integrated grill molding enterprises are committed to developing environmentally friendly plastic materials and promoting energy conservation and emission reduction in radiator grille molding process. For example, the use of biodegradable plastics is increasing, and the energy consumption in the bumper integrated grill molding process is gradually controlled.

Precision and customization: With the diversification of product demand, precision bumper integrated grill molding and customized grille housing plastic molding technology have been widely used. Especially in the fields of medical treatment, electronics and electric vehicles, precision grille housing plastic molding can meet the requirements of high precision and complex structure.

5. Global market competition pattern of grille housing plastic mold

In recent years, the trend of M&A and integration in the global bumper integrated grill molding industry is remarkable. Large enterprises further consolidate their market position by acquiring small innovative enterprises, expanding production capacity and technical reserves. At the same time, the cooperation between enterprises in the bumper integrated grill molding industry is also increasing, especially in technology sharing, production resource integration and supply chain coordination, which promotes the overall competitiveness of the industry.