KINGREAL UNIVERSAL IND., LTD

Phone

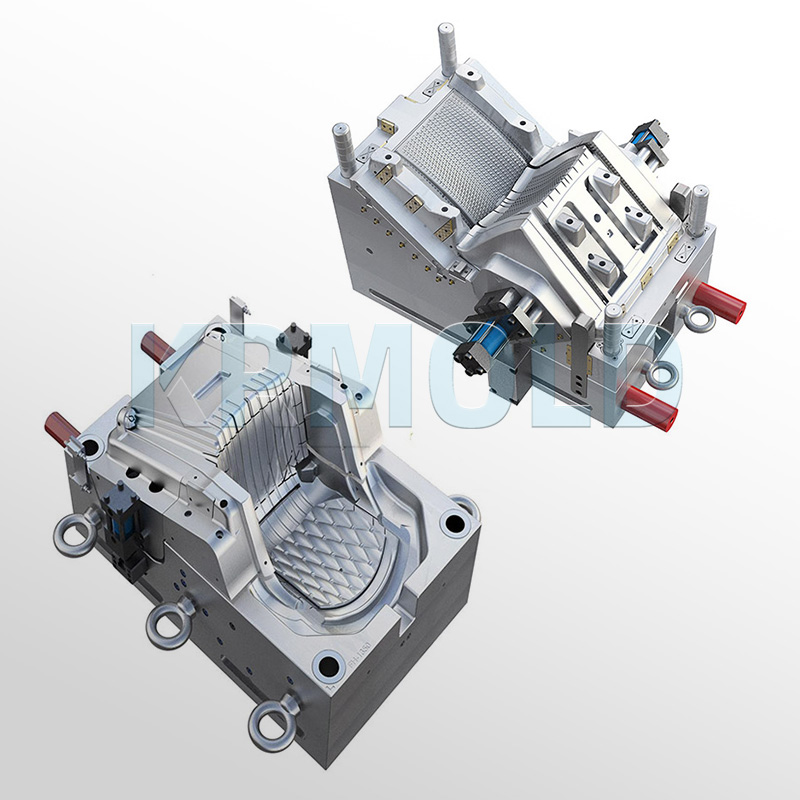

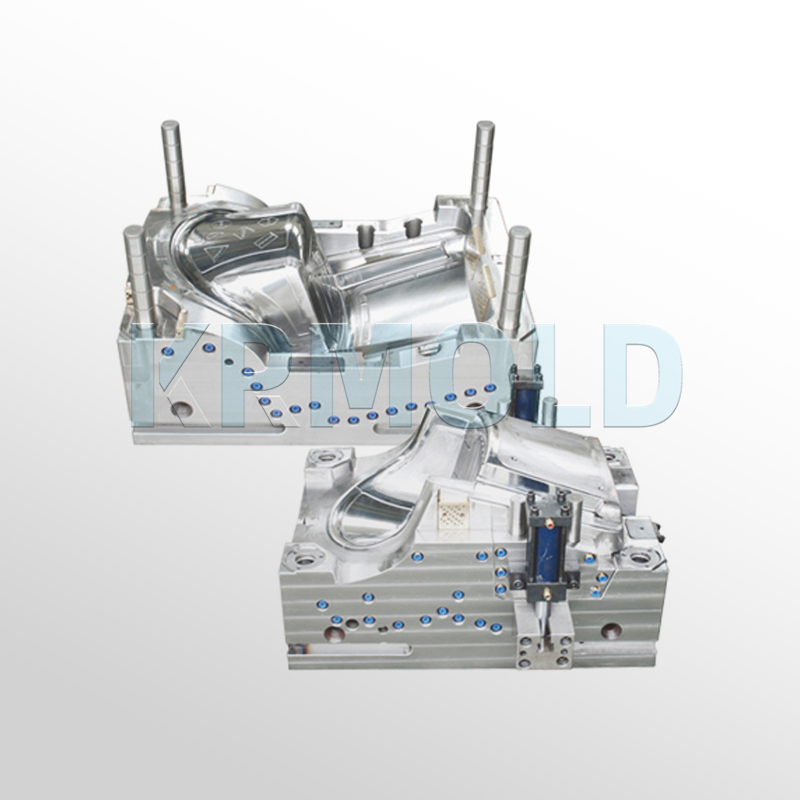

+86-13702855825Plastic chair injection molds are specifically designed to shape molten plastic into chair shapes. The molding process is efficient and highly repeatable. The plastic is first heated and melted into a viscous liquid, which is then poured into plastic chair injection mould. After cooling, the final shape of the chair is formed. Plastic chair injection molds are typically made of robust metal materials (such as steel or aluminum), enabling large-scale production in large factories and are widely used in various commercial and residential environments.

1. Plastic Chair Injection Mold Materials and Costs

Cheap plastic chair injection mould materials will help to significantly lower plastic chair injection mold production costs and so lower total manufacturing expenses. Usually, several elements affect the cost of plastic products: the market price of raw materials, manufacturing difficulty, and market supply and demand. Pricing for a plastic substance is often rather low if it is quite competitive and easily available; this favorably affects plastic chair injection mould production expenses.

Among many plastic materials, PS (polystyrene), PE (polyethylene), and PP (polypropylene) are widely considered relatively inexpensive options.

1.1

PS (Polystyrene) for plastic chair injection mold

PS is a widely used thermoplastic whose raw ingredients are fairly easy to acquire. Moreover, polystyrene's manufacturing method is somewhat simple hence lowering its production costs as it is rather simple to process. Superior insulation and strong impact resistance are among polystyrene's amazing physical qualities that make it appropriate for plastic chair injection mould manufacture.

1.2

PE (Polyethylene) for plastic chair injection mold

Polyethylene is known for its flexibility and toughness, maintaining good performance even in extremely low-temperature environments. Its manufacturing process is very sophisticated and able to satisfy the demands of bulk output. Hence, among the often used materials in plastic chair injection molds, PE possesses a major cost advantage.

1.3

PP (Polypropylene) for plastic chair injection mold

PP is widely used in the processing of plastic chair injection mould. It has excellent flowability, good chemical corrosion resistance, and good flexural fatigue resistance. In the production process, polypropylene not only has lower costs but also helps to improve the overall quality of plastic chairs.

One should keep in mind that the cost of plastic products will vary depending on region, brand, market supply and demand, and other variables. Hence, selecting an appropriate plastic chair injection mold calls for thorough consideration of particular needs and budget.

2. Advantages of Using Plastic Chair Injection Molds

2.1 High production speed Plastic chair injection molds can quickly complete mass production. Usually the equipment can create a chair in only a few seconds once the plastic chair injection mould is ready. This quick manufacturing process lets businesses send hundreds of chairs quickly, therefore solving a need for consumers with urgent needs for great numbers of products.

2.2 Cost-Effectiveness The production cost of using plastic chair injection molds is relatively low. Though the initial outlay on the plastic chair injection mould might be more, its reusable feature greatly lowers the chair's production cost. Parallel with this, the automatic manufacturing system lowers dependence on human labor, hence cutting labor expenses.

2.3 Consistent Quality Every chair generated is nearly identical in look and feel thanks to the same plastic chair injection mold. This consistency guarantees great product quality and so builds consumer confidence by lowering the chance of mistakes and damage.

2.4 Durability Chairs produced using plastic chair injection mould are not only aesthetically pleasing but also very sturdy and durable. These chairs are perfect for usage in indoor as well as outside situations since they are cold-proof, chemical corrosion resistant, strong and not easily broken. They can withstand considerable weights. |  |

2.5 Reduced Waste Production using plastic chair injection mould generates almost no excess waste. The equipment only needs to inject a suitable amount of plastic; the remaining plastic can usually be recycled. Using less raw material not only benefits environmental protection but also effectively reduces production costs.

2.6 Easily Add Colors and Styles In plastic chair injection mold, designers can easily add a variety of colors and styles to the chairs. The desired color can be added before the plastic enters the plastic chair injection mould, allowing the chair to have the applied color appearance without the need for post-painting. Moreover, the chair becomes more eye-catching as custom forms and brand emblems can be developed.

2.7 Safe and Ergonomic With the advanced technology of plastic chair injection mold, ergonomic chair designs can be easily created. Designers can freely construct the chair's curves, armrests, and backrest, ensuring customer comfort during use. At the same time, these designs reduce the risk of edge damage, making the chair safer to use. |  |

The application of plastic chair injection mould has brought revolutionary changes to the manufacturing industry, not only reducing production costs but also improving efficiency and product quality. Among numerous plastic materials, PS, PE, and PP stand out due to their cost advantages and good performance, becoming the most affordable and practical plastic choices for plastic chair injection mould.

In the modern industrial environment, choosing the right plastic chair injection mold, material, and configuration not only improves production efficiency but also meets the market's demand for high-quality products. Therefore, for potential manufacturers, a thorough understanding of the advantages of plastic chair injection mould and their corresponding material properties is crucial to standing out in the fierce market competition and gaining more customer trust and support.

Feel free to contact KRMOLD for more information on plastic chair injection mould!