KINGREAL UNIVERSAL IND., LTD

Phone

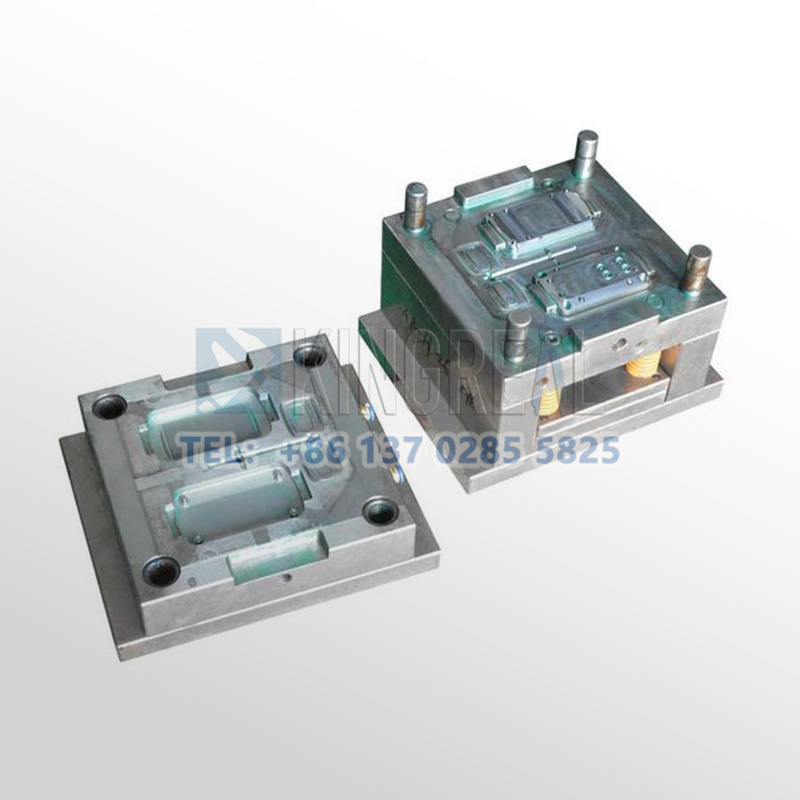

+86-13702855825In this article, KRMOLD will introduce the basic principles of plastic injection molds in detail. If you are interested in sensor mounts injection mold, please consult us!

| 1 | Definition of sensor mounts injection molding |

| 2 | Basic principle of charging dock injection mold |

| 3 | Forming cycle of charging dock injection mold |

1.Definition of sensor mounts injection molding

Charging dock injection molding, is a molding method of injection and molding. The smart home integration injection molding method has the advantages of high production speed, high efficiency, automatic operation, various colors, simple shapes, large sizes, accurate product sizes, easy product upgrading, and being able to form parts with complex shapes. Charging dock injection molding is suitable for mass production and products with complex shapes. At a certain temperature, the completely melted plastic material is stirred by a screw, injected into a smart home integration injection mold cavity with high pressure, and cooled and solidified to obtain a molded product. This method is suitable for mass production of parts with complex shapes and is one of the important processing methods.

2.Basic principle of charging dock injection mold

The basic principle of sensor mounts injection mold mainly includes four aspects: temperature control system, molding parts, structural parts and exhaust system. These principles together ensure the shape, size, quality and production efficiency of plastic products.

(1)Temperature control system: in order to meet the requirements of injection process for mold temperature, a temperature control system is needed to adjust the mold temperature. For the smart home integration injection mold for thermoplastic, the cooling system is mainly designed to cool the charging dock injection mold. The common way to cool the mold is to open a cooling water channel in the sensor mounts injection mold, and use the circulating cooling water to take away the heat of the charging dock injection mold; In addition to using hot water or steam in cooling water channel, electric heating elements can be installed inside and around the mold for heating the charging dock injection mold.

(2)Molding part: It consists of a core and a female die. The core forms the inner surface of the product, and the female die forms the outer surface shape of the product. After the charging dock injection mold is closed, the core and cavity form the cavity of the smart home integration injection mold. According to the requirements of technology and manufacturing, sometimes the core and die are composed of several blocks, and sometimes they are made into a whole, and inserts are only used in the parts that are easy to be damaged and difficult to process.

(3)Structural parts: including guiding, demoulding, core-pulling and parting parts, such as front and rear clamping plates, front and rear fastening templates, bearing plates, bearing columns, guiding columns, demoulding plates, demoulding rods and return rods. Guide parts In order to ensure that the moving die and the fixed die can be accurately centered when clamping, four groups of guide posts and guide sleeves are usually used to form the guide parts. Pushing-out mechanism In the process of charging dock injection mold opening, it is necessary to have a pushing-out mechanism to push out or pull out plastic products and their solidified materials in the runner. Side core-pulling mechanism For plastic products with side recesses or side holes, side parting must be carried out before being pushed out, and the side core can be successfully demoulded after being pulled out.

(4)Exhaust system: a groove-shaped air outlet opened in the smart home integration injection mold to exhaust the original and molten gas. When the melt is injected into the mold cavity, the air originally stored in the mold cavity and the gas brought in by the melt must be discharged out of the charging dock injection mold through the exhaust port at the end of the material flow, otherwise, the product will have air holes, poor connection and insufficient sensor mounts injection mold filling, and even the accumulated air will burn the product due to high temperature caused by compression. Don't point the exhaust port at the operator, so as to avoid accidental discharge of molten material and personal injury. These basic principles work together to ensure that the charging dock injection mold can produce plastic products that meet the requirements efficiently and accurately.

3.Forming cycle of charging dock injection mold

The time required to complete a charging dock injection molding process is called molding cycle, also called smart home integration injection molding cycle. It actually includes the following parts: molding cycle: molding cycle directly affects labor productivity and equipment utilization. Therefore, in the production process, we should try our best to shorten the relevant time in the molding cycle on the premise of ensuring the quality. In the whole molding cycle, injection time and cooling time are the most important, which have a decisive influence on the quality of products. The filling time in injection time is directly inversely proportional to the filling rate, and the filling time in production is generally about 3-5 seconds. The pressure holding time in the injection time is the pressure time on the plastic in the cavity, which accounts for a large proportion in the whole injection time, generally about 20-120 seconds (up to 5-10 minutes for extra-thick parts). Before the melt at the gate is frozen, the holding time has an influence on the dimensional accuracy of the product, and if it is later, it has no influence. The holding time also has a maximum value, which is known to depend on the material temperature, smart home integration injection mold temperature and the size of the main runner and gate.

If the dimensions of the main runner and gate and the process conditions are normal, the pressure value with the smallest fluctuation range of the shrinkage of the product is usually taken as the standard. The cooling time mainly depends on the thickness of the product, the thermal and crystallization properties of the plastic, and the mold temperature. The end point of cooling time should be based on the principle of ensuring that the product will not change when demoulding, and the cooling time is generally about 30~120 seconds. It is unnecessary to have a long cooling time, which not only reduces the production efficiency, but also causes difficulties in demoulding complex parts, and even produces demoulding stress when forcibly demoulding. The other time in the charging dock injection molding cycle is related to whether the production process is continuous and automatic, and the degree of continuous and automatic.