KINGREAL UNIVERSAL IND., LTD

Phone

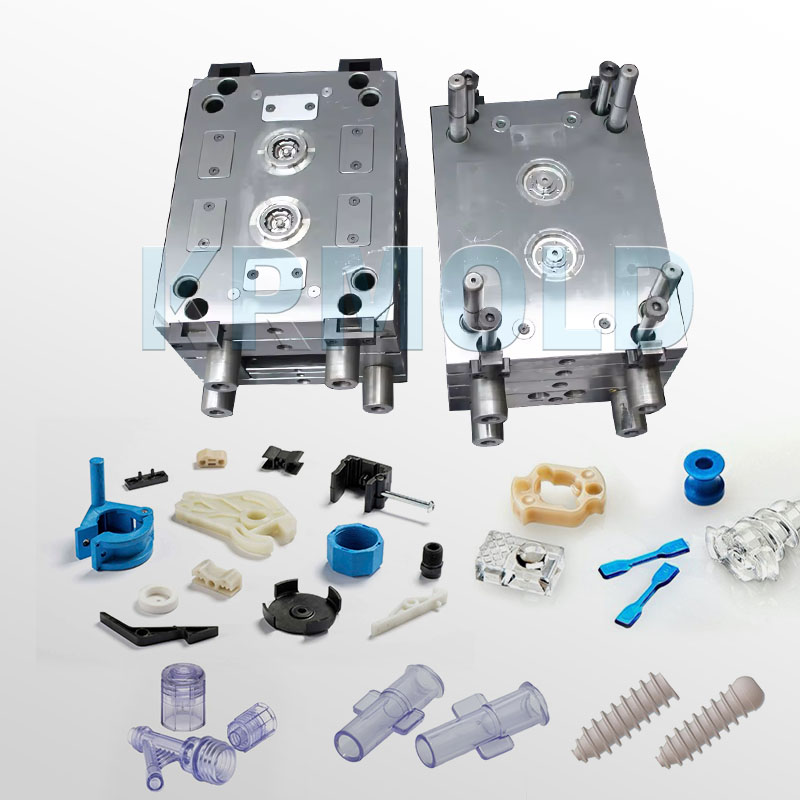

+86-13702855825Micro injection moldsare used to produce products with overall size, functional characteristics or tolerance requirements in millimeters or even microns. Because of the miniature characteristics of molded products, special molding machinery and auxiliary equipment are needed to complete various production operations. Such as injection quantity control, mold emptying (vacuum), injection, product ejection, inspection, separation, operation, storage, positioning and packaging. The manufacture of mold inserts and mold cavities also requires special technology.

| 1 | Advantages of Micro Injection Molding |

| 2 | Application Scope of Micro Gear Injection Molds |

| 3 | Typical Application of Micro Injection Molding |

| 4 | Technological Characteristics of Micro Gear Injection Molds |

1. Advantages of Micro Injection Molding

(1) High precision: Micro-injection molding can produce parts with high dimensional precision and complex shape, which is suitable for micro-products with high performance requirements.

(2)Flexible batch: Micro injection molding can be produced in small or large batches according to demand to meet the needs of different markets.

(3) Wide range of materials: Micro injection molding can be used for injection molding of various plastic materials, including thermoplastics and thermosetting, plastic, etc.

(4) The equipment cost is relatively low: Compared with the large injection molding machine, the equipment cost required for micro injection molding is lower and the investment return period is shorter.

(5) Environmental protection and energy saving: low energy consumption during micro injection molding helps to reduce production cost and environmental impact.

2. Application Scope of Micro Gear Injection Molds

(1) Micro-products: Micro-products with a weight of microgram or a fraction of a gram and a size of millimeter or less, such as micro-gears and micro-joysticks;

(2) Micro-tolerance products: high-precision products with arbitrary size, but the tolerance range of size requirements is measured in micron level, such as connectors for optical fibers;

(3) Products with microstructure features: products with special structural requirements, such as optical disks with data gaps and lenses with micro-surface features.

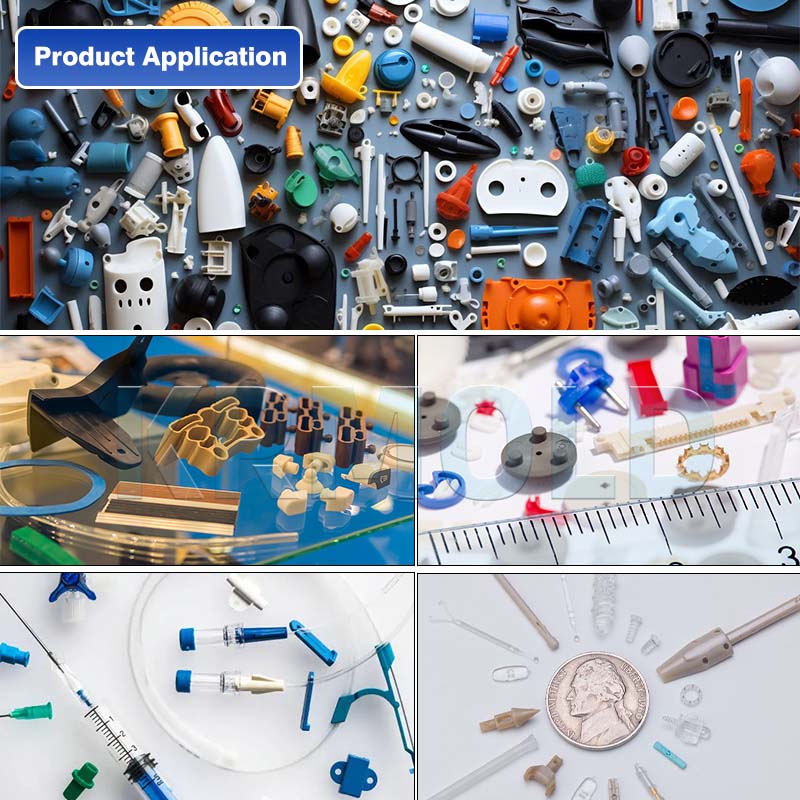

Typical Application of Micro Injection Molding

In the fields of optical communication, computer data storage, medical technology, biotechnology, sensors and transmission devices, micro-optical devices, electronics and consumer products, as well as equipment manufacturing and mechanical engineering, micro injection molding products show a rapidly growing demand.

Typical examples include: watch and camera parts, car bumpers, acceleration and distance sensors, hard disk and optical disk drive heads, medical sensors, micropumps, bobbins, high-precision gears, pulleys, spiral tubes, optical fiber switches and connectors, micromotors, surgical instruments and communication products.

3. Technological Characteristics of Micro Gear Injection Molds

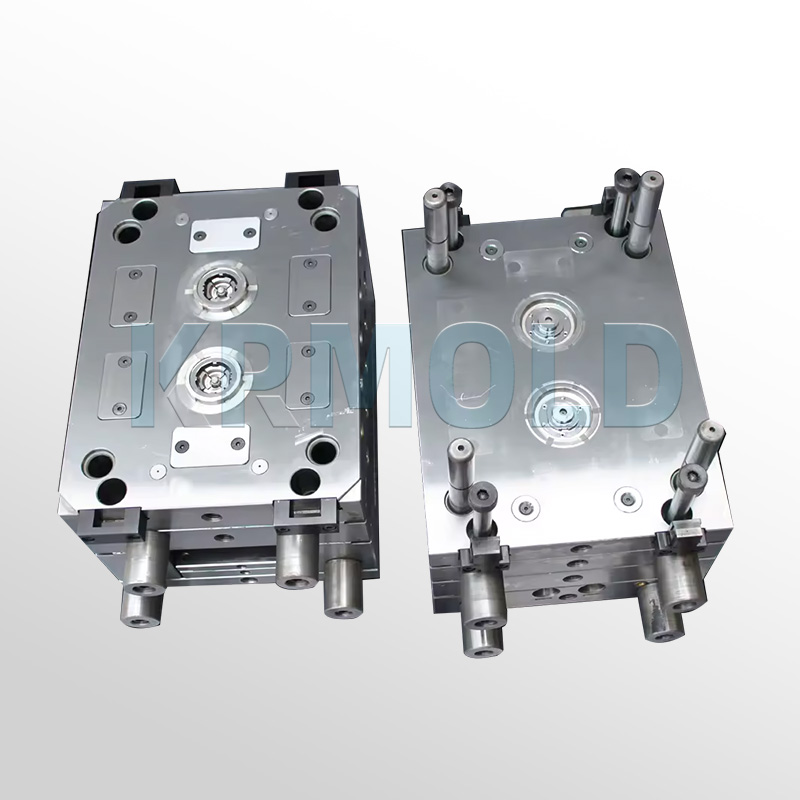

(1)Special process parameter requirements

Micro injection molding products are small in size, special in shape and complex in functional areas, generally in the order of several microns to several centimeters, and the aspect ratio is between 1 and 100. Some functional areas require extremely high strength, smoothness and transparency. In order to achieve high reproducibility of these features, there are special requirements in the process. During micro injection molding, high injection speed and high injection pressure (up to hundreds to thousands of kg/cm) are needed to ensure that the plastic melt can fill the micro gear injection molds cavity quickly and accurately. At the same time, try to increase the feed temperature, reduce the melt viscosity and promote the melt flow within the allowable range. The micro gear injection molds wall temperature should also be controlled at a high level, which is beneficial to the flow and molding of plastic melt.

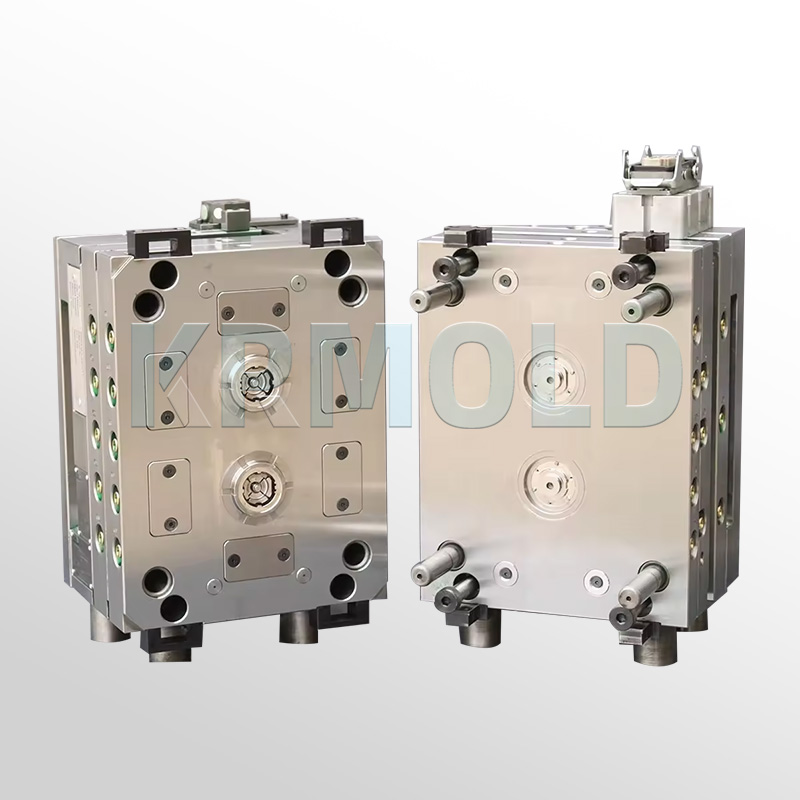

(2) Special mold temperature control system

In order to meet the demand of micro injection molding for dynamic control of micro gear injection molds temperature, the mold needs to be equipped with a special separate heating and cooling system. In the mold filling stage, higher mold temperature is beneficial to the flow of plastic melt and ensures the cavity to be fully filled; In the cooling stage, the lower mold temperature accelerates the cooling and curing of the product and shortens the micro injection molding cycle. Therefore, process control often needs to use two oil circuits with different temperatures to heat and cool the micro gear injection molds in the mold filling and cooling stages respectively, so as to realize accurate control of the mold temperature.

(3) Advanced auxiliary equipment configuration

In order to effectively control the production process and handle and package micro injection molding products, the mold needs to be equipped with a series of advanced auxiliary equipment. The improved mold sensor can monitor the internal temperature, pressure and other parameters of the micro gear injection molds in real time, and provide accurate basis for process adjustment. High-precision micro gear injection molds guide device ensures accurate positioning when the micro gear injection molds are opened and closed, and ensures the dimensional accuracy of the product; The mold evacuation system can eliminate the air in the mold cavity and avoid the defects such as air holes in the products; The integrated runner collector can collect and treat the waste in the runner and improve the material utilization rate; The manipulator and automatic gate cutting system used for taking out products realize the automation of production process and improve production efficiency; The mold cleaning system activated every cycle ensures the micro gear injection molds to be clean and maintain the micro gear injection molds in good working condition. These equipments are very important for the correct production and collection of micro-injection molded products.

(4) Diversity of material selection

From the material point of view, many materials suitable for macro-molding can be used for micro injection molding. Common micro injection molding materials include polyoxymethylene (POM), polycarbonate (PC), polymethylmethacrylate (PMMA), nylon (PA), liquid crystal polymer (LCP), polyetherimide (PEI) and silicone rubber. When it comes to reactive injection, materials based on acrylic acid, acrylamide and siloxane have also been used. Rich material selection makes it possible for micro injection molding products to meet different fields and different performance requirements.