KINGREAL UNIVERSAL IND., LTD

Phone

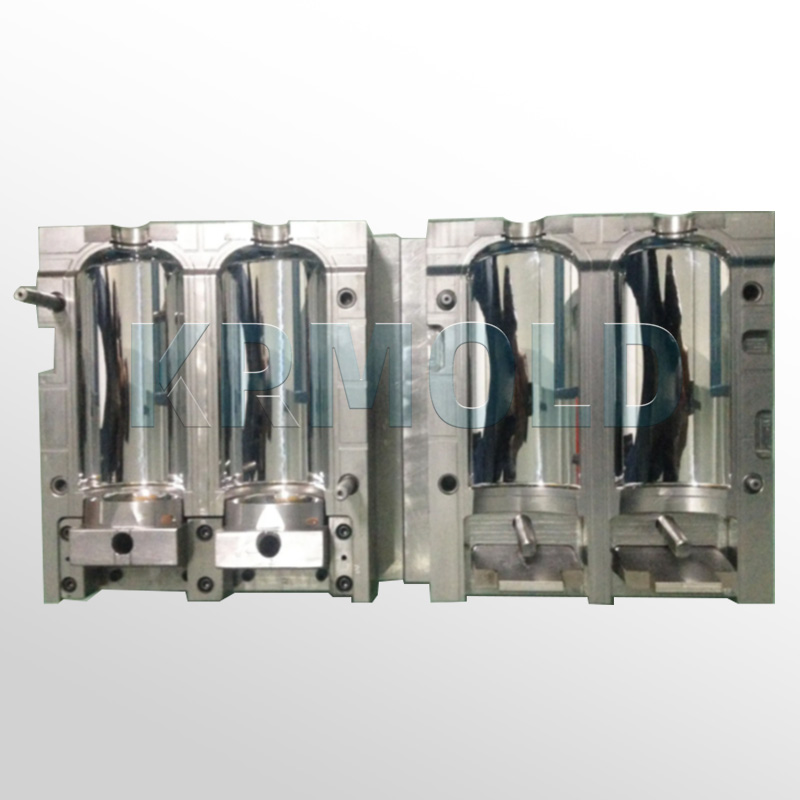

+86-13702855825Gas assist injection molding, as an innovative injection process, its core lies in the introduction of gas injection molding in the injection process. This technology injects compressed air or nitrogen into the mold cavity while injecting plastic melt through the gas assist injection molding machine, so that the plastic expands under gas pressure and clings to the mold surface, and finally forms an accurate product shape. This mechanism not only significantly improves the dimensional accuracy and quality of injection molded parts, but also effectively eliminates internal bubbles and gray glue, and improves the yield and product quality.

| 1 | Principle of Gas-assisted Injection Molds |

| 2 | Advantages of Gas-assisted Injection Molds |

| 3 | Main Applications of Gas Injection Molding |

1.Principle of Gas-assisted Injection Molds

2.Advantages of Gas-assisted Injection Molds

(1)Reduce product residual stress and ensure product shape stability.

In the process of gas injection molding, high-pressure gas is introduced into the plastic melt, and the plastic melt is more evenly distributed and cooled in the gas-assisted injection molds through the uniform pressure of the gas. This process greatly reduces the residual stress inside the product, so that the product can maintain a stable shape after gas injection molding, effectively avoiding the emergence of deformation problems. For example, in the production of automobile interior parts, many parts are complex in shape and large in size. After gas injection molding is adopted, the residual stress of the products is significantly reduced, the shape accuracy and stability of the products are greatly improved, and the strict requirements of the automobile industry for high-quality interior parts are met.

(2)Solve the problem of product surface shrinkage marks.

The surface shrinkage of products has always been a thorny problem in the field of gas injection molding, especially in the production of products with large thickness changes. Gas injection molding provides an effective solution to this problem. In the thick-walled part of the product, high-pressure gas is injected to form an air passage, and the pressure of the gas continuously acts on the plastic melt, which compensates the volume change of the thick-walled part caused by cooling shrinkage, thus effectively solving and eliminating the problem of shrinkage marks on the product surface. Taking the production of large-scale household appliance shells as an example, there are often areas where the thickness changes greatly. After gas injection molding is adopted, the problem of shrinkage marks on the product surface is perfectly solved, the product appearance is smoother and smoother, and the overall quality and market competitiveness of the product are improved.

(3)Shorten the product forming cycle and improve the production efficiency.

Due to the introduction of gas, the flow resistance of plastic melt in the gas-assisted injection molds is reduced and the filling speed is accelerated, thus shortening the injection time. Moreover, the gas channel formed in the product contributes to the uniform heat transfer, accelerates the cooling speed of the product and further shortens the molding cycle. For example, in the toy manufacturing industry, many products have complex structures and large production batches. After adopting gas injection molding, the production efficiency has been greatly improved, and enterprises can complete order delivery in a shorter time to meet the market demand.

(4)Save plastic raw materials

Gas injection molding realizes efficient saving of plastic raw materials through unique process principle, and the highest saving rate can reach 30%. In traditional injection molding, in order to ensure the quality of products, it is often necessary to use more plastic melt to fill the mold cavity. Gas injection molding uses the support of gas to form a hollow structure inside the product, which reduces the use of plastic. For example, in the production of furniture accessories, many parts adopt gas injection molding, which not only ensures the strength and performance of products, but also greatly reduces the cost of raw materials and brings considerable economic benefits to enterprises.

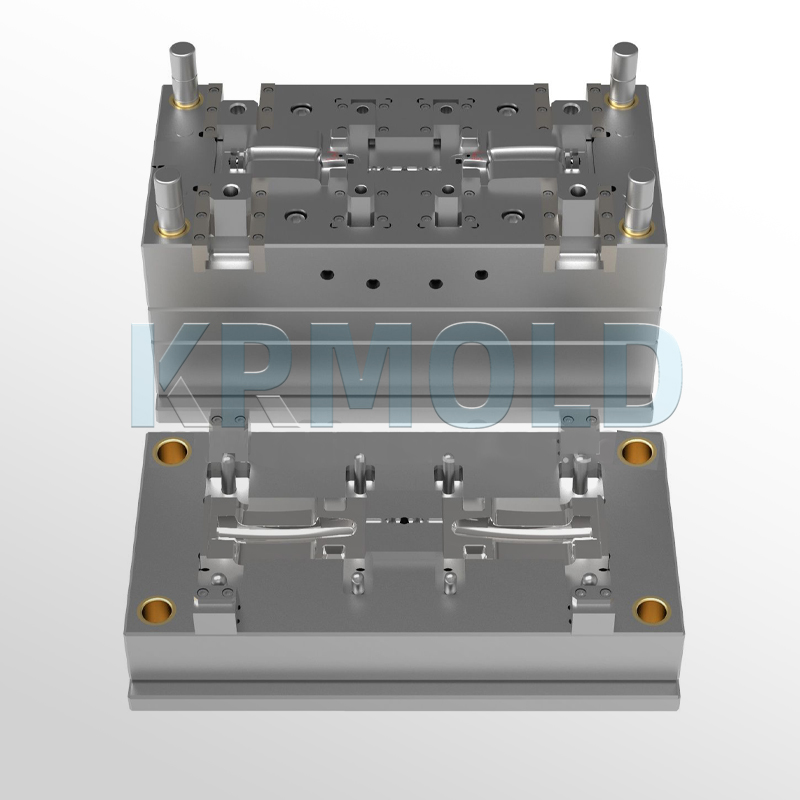

(5)Extend the service life of the mold

The clamping force of injection molding machine and the pressure in the mold cavity are important factors affecting the service life of equipment and gas-assisted injection molds. Gas injection molding has obvious advantages in this respect. Because the introduction of gas shares the pressure of plastic melt on the mold wall, the pressure in the mold cavity is significantly reduced. At the same time, with the aid of gas, the plastic melt is easier to fill the mold cavity, and the required injection pressure is correspondingly reduced, thus reducing the clamping force of the injection molding machine. This not only reduces the loss of the molding machine, but also improves the working life of the injection molding machine. For the gas-assisted injection molds, the lower pressure in the mold cavity effectively reduces the wear and deformation of the mold and prolongs the service life of the gas-assisted injection molds. For example, in the production of electronic equipment shell, the long-term use of gas assist injection molding greatly reduces the maintenance cost of injection molding machine and mold, prolongs the replacement cycle of equipment and gas-assisted injection molds, and saves a lot of equipment investment and maintenance costs for enterprises.

(6)Provide a new choice for mold material selection of special plastic products.

For some special plastic products, traditional mold materials may not meet the production needs. The emergence of gas injection molding provides a new choice for mold material selection of this kind of products. Due to the low pressure in the mold cavity during gas assist injection molding, the strength requirements of mold materials are relatively reduced, so the gas-assisted injection molds can be made of aluminum alloy. Aluminum alloy has the advantages of light weight, good processability and excellent thermal conductivity. Using aluminum alloy material to make molds can not only reduce the manufacturing cost of gas-assisted injection molds, but also improve the production efficiency of molds. For example, in the production of some small precision plastic products, using aluminum alloy mold combined with gas assist injection molding can quickly and accurately produce high-quality products and meet the market demand for such products.

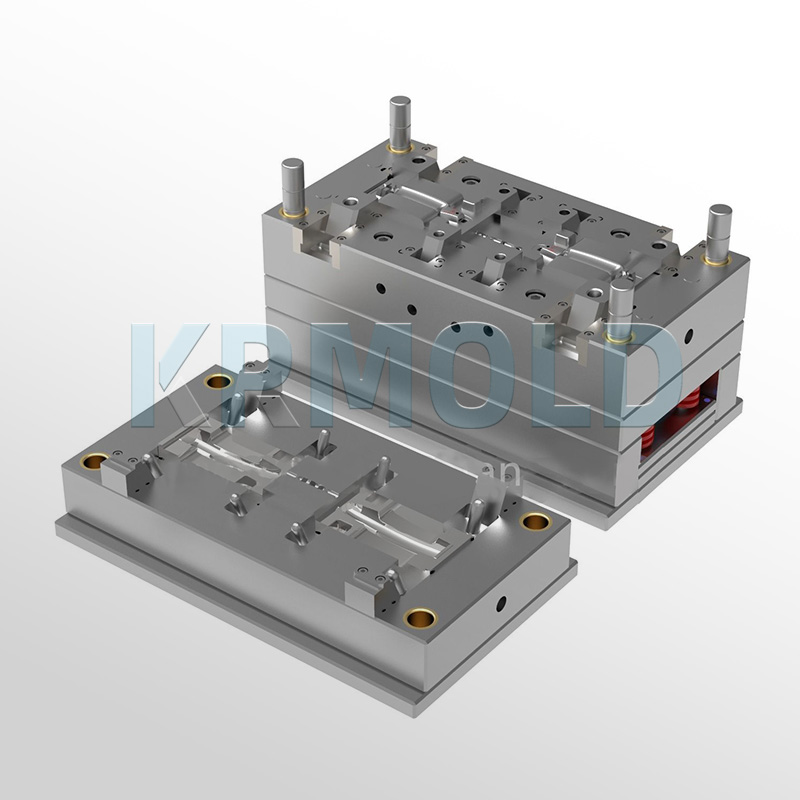

(7)Simplify the complicated design of products

The application of gas assist injection molding brings greater freedom to product design and can help simplify product design. Through the airway structure formed by gas in the product, some functions that originally required complex structural design can be realized. For example, in the design of some handle products, gas assist injection molding is used to form a hollow structure inside the handle, which not only reduces the weight of the product, but also improves the grip comfort of the handle, and simplifies the design and manufacturing process of the product.

3.Main Applications of Gas Injection Molding

At present, the application of gas injection molding focuses on thicker plastic products, such as handles, handrails, hangers, hangers, furniture, soles, etc. Plates such as TV shell, desktop, car bumper, etc.

In the past, due to the large area or thick wall of these plastic products, the deformation and warpage of the products were inevitable and difficult to solve during injection molding, so they could only be manufactured by the method of clamping steel in the center or giving up plastic manufacturing. For example, the armrest of a solid chair made of plastic often deforms. In fact, the armrest of the chair is not required to bear much gravity, and the hollow armrest can also support the weight of the hand. Now, with the gas injection molding, the armrest is no longer deformed and the appearance can be more beautiful.

For another example, the plastic steering wheel used in the automobile industry is also a product with a thick wall. Before the hydraulic steering wheel was invented, the mechanical strength of the steering wheel was very high, and the steel ring must be sandwiched in the plastic steering wheel. The steering wheel is heavy and requires a lot of materials. The manufacturing process is complicated and the cost is high.

After the invention of the hydraulic steering wheel, the required mechanical strength of the steering wheel is greatly reduced, and with the gas assist injection molding, the non-deformation hollow plastic steering wheel can be made, and the product has been greatly improved in terms of aesthetics, materials, manufacturing time and product cost.