KINGREAL UNIVERSAL IND., LTD

Phone

+86-13702855825| 1 | Advantages of Automotive Injection Molding |

| 2 | Applications of Automotive Injection Molding |

| 3 | Material and Design Considerations for Automotive Injection Molding |

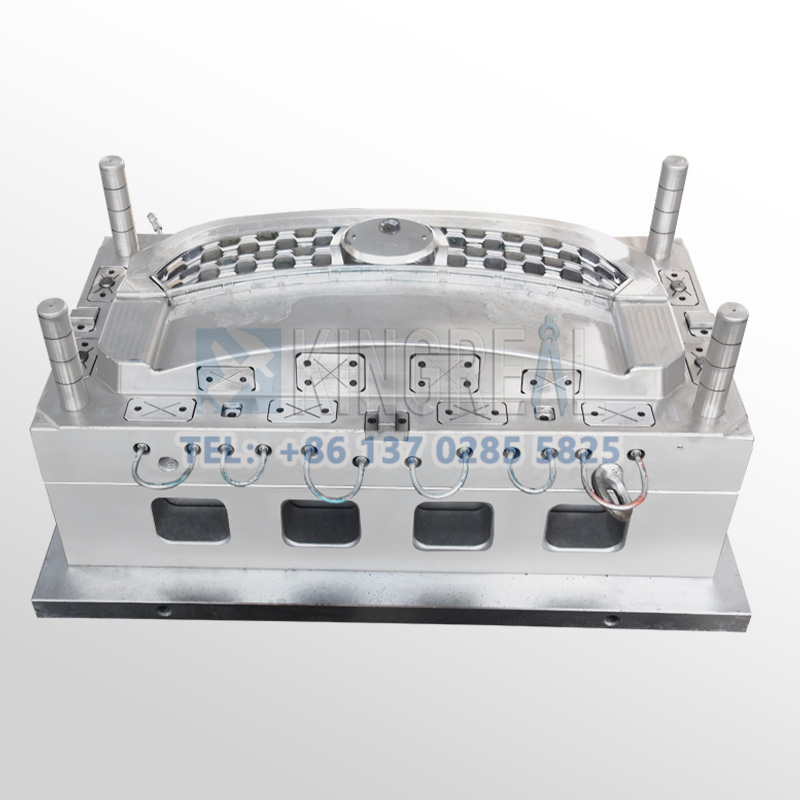

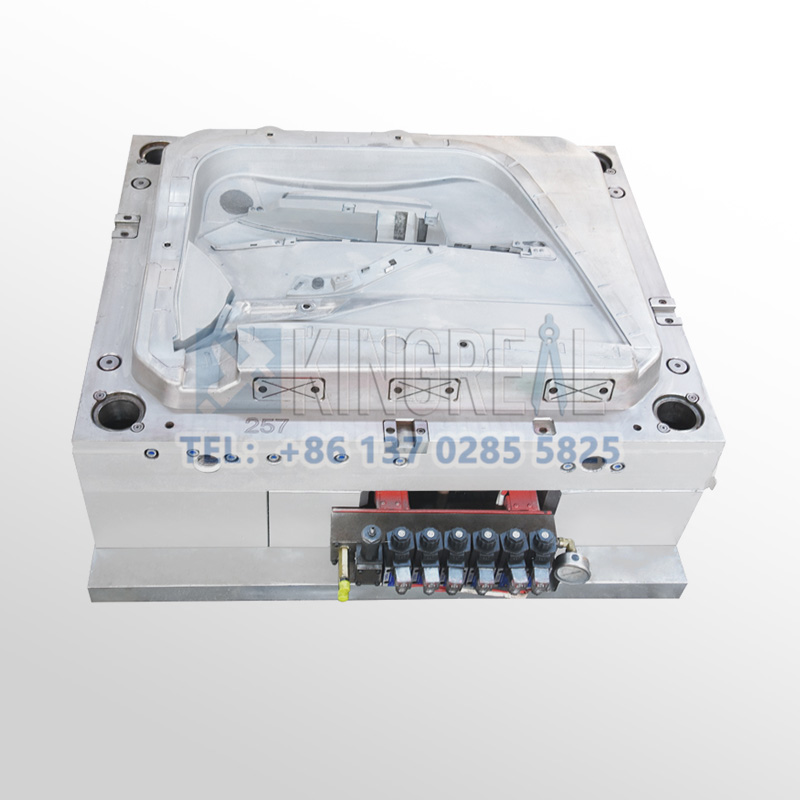

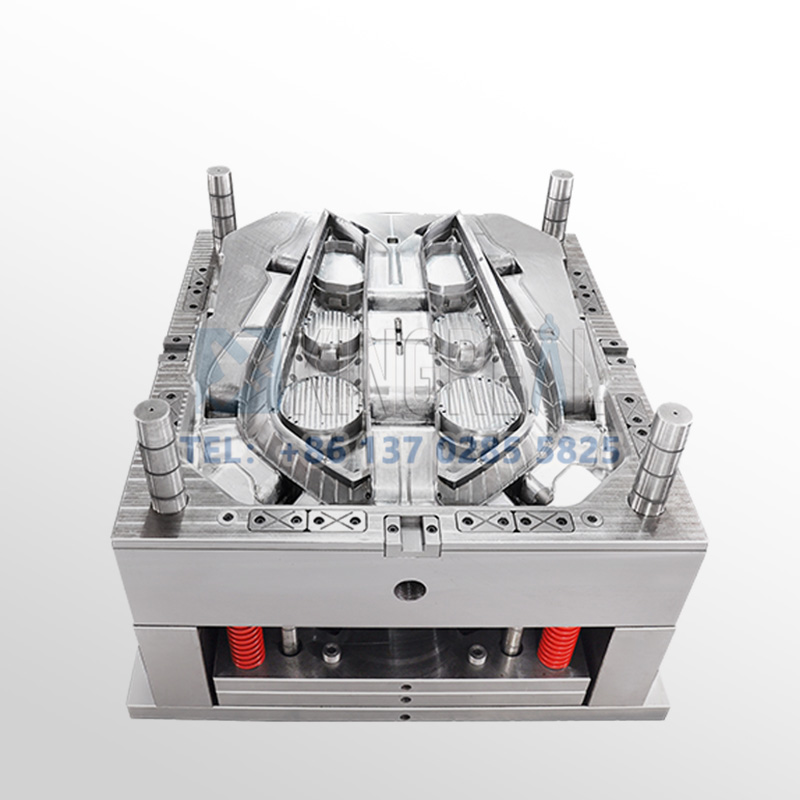

Using plastic injection molding, automotive injection molding is a method for manufacturing several plastic automotive parts. Through fast manufacturing and automation, this technology lowers production expenses and lowers waste in addition to providing lightweight, durable, and affordable automobile components. It is an affordable choice for mass manufacturing. Advanced automotive plastic part injection molding technology not only offers long-run worth for manufacturing but also improves efficiency and helps in the acceptance of new manufacturing techniques.

1/Advantages of Automotive Injection Molding

1. High precision for automotive injection molding

One of the main benefits of automotive injection molding is its great accuracy. A vital element of the auto industry, this process helps to lower the margin of error in automotive components creation. Performance and safety of the whole vehicle can be affected by even the tiniest imperfections. Automotive plastic part injection molding lowers manufacturing expenses in addition to enhancing vehicle safety and performance by customizing polymer materials to certain performance demands.

The flexibility of automotive injection molding technology, for instance, enables the design and manufacture of interior and exterior parts like instrument panels and bumpers. allowing complicated geometries and surface treatments improves general appearance and utility.

2. Improving overall vehicle performance and safety

Complex geometries made by automotive plastic part injection molding help to lower the weight of automobile parts and so boost general performance. This is very important for the development of vehicle technology. For instance, light plastic parts help to maximize vehicle fuel efficiency and lower emissions. Automotive manufacturing's application of injection molded components shows how crucial it is for raising safety and vehicle performance.

3. High-volume production capabilities for automotive injection molding

High-volume manufacturing benefits especially from automotive injection molding. The technology's efficiency allows companies to rapidly make significant numbers of parts to satisfy consumer need. Automation and cutting-edge injection molding equipment guarantee uniform product quality and greatly minimize human mistake during the manufacturing process. This efficiency helps carmakers to keep their edge in a very competitive market.

2/ Applications of Automotive Injection Molding

Automotive plastic part injection molding technology is widely used in the automotive industry, producing virtually all automotive parts, from engine components to interior and exterior trim. The following are some key application areas:

1. Engine Components

In engine components especially, injection molded components assume great significance. Automotive plastic part injection molding technology enables the creation of intricate geometries, hence lowering weight and boosting engine efficiency; these parts must resist intense pressures and temperatures. Automotive plastic part injection molding is frequently employed, for instance, to make intake manifolds and valve covers, therefore lowering total weight and boosting thermal efficiency, hence boosting engine performance.

2. Interior and Exterior Components

Automotive injection molding also helps to define the beauty and utility of automotive interior and outside parts. This technique allows producers to produce components with complex patterns and high-end finishing—for instance, instrument panels, bumpers, and decorative strips. Automotive injection molding also improves the resistance of the parts to environmental variables, hence improving the whole car experience.

3. Electrical and Electronic Systems

Components produced by automotive plastic part injection molding are essential in car electrical systems. Shielding sensitive electronic equipment from environmental elements, these parts offer protective housing for them. Automotive injection molding, for instance, can create parts like connectors and enclosures that offer dependable isolation and protection for automotive electronic systems, therefore guaranteeing safety and performance.

3/ Material and Design Considerations for Automotive Injection Molding

Choosing the correct material and executing suitable design are critical for automotive plastic part injection molding to be effective. Materials meeting strict criteria for strength, durability, heat resistance, and chemical resistance are also required by the car industry to help lighter and more efficient vehicle designs. To satisfy automotive applications, automotive plastic part injection molding sector has created a broad spectrum of sophisticated polymers and composite materials.

1. Material selection for automotive plastic part injection molding

Among other criteria, engineers have to take into account the performance qualities of the substance when choosing it. While an engine part demands high thermal stability, for instance, a bumper must have great impact resistance. Use of lightweight materials not only lowers vehicle weight and boosts fuel efficiency but also cuts emissions as sustainability gets more focus. support manufacturers in meeting ever stricter regulatory requirements.

2. Design considerations for automotive plastic part injection molding

Beyond material characteristics, design choices involve component manufacturability. The ultimate quality of the component is influenced by mold design, material flow during the automotive plastic part injection molding process, and the effectiveness of the cooling system. Companies can develop solutions that maximize performance and raise manufacturing efficiency by means of a fine balance of these components.

KRMOLD is an automotive injection mold manufacturer with over 20 years of experience. KRMOLD can provide a variety of automotive injection molding technologies according to the different needs of our customers. If you are interested in this, please feel free to contact KRMOLD!