KINGREAL UNIVERSAL IND., LTD

Phone

+86-13702855825In all kinds of plastic injection molding, high-precision two-color injection molds occupy an extremely important position with its unique performance and advantages. It brings new possibilities for the production of plastic products and greatly expands the design space and application fields of products. Next, KRMOLD will introduce all aspects of the double injection molding to you.

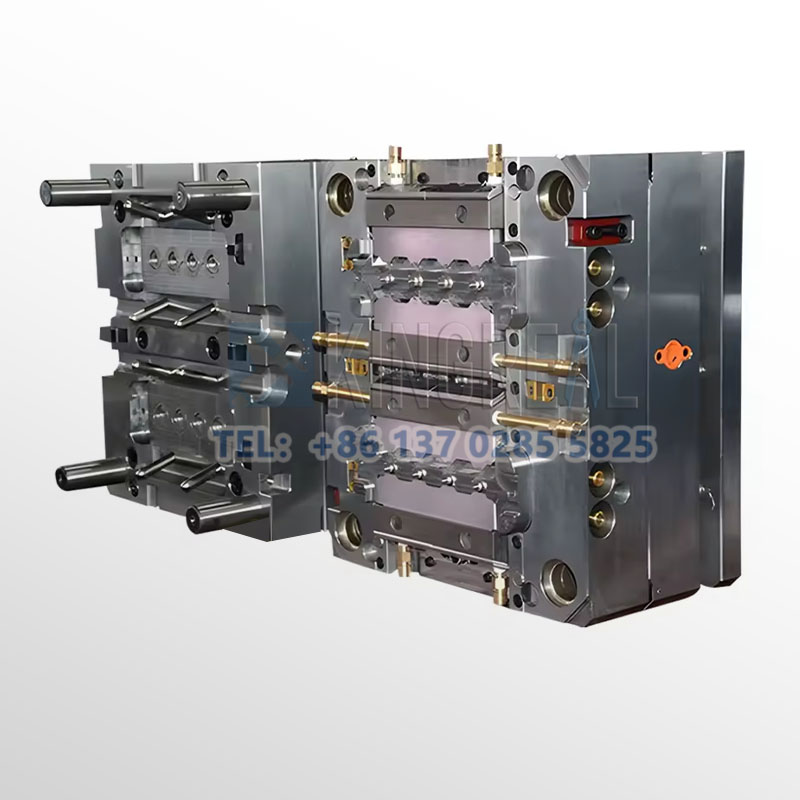

Structure of double injection molding

The structure of the high-precision two-color injection molds are exquisite, which is mainly composed of an upper mold plate, a lower mold plate, a moving mold plate, a static mold plate and two coaxial injectors. In the double injection molding operation, it can inject two different materials at the same time, and then create plastic products with different colors or different properties.

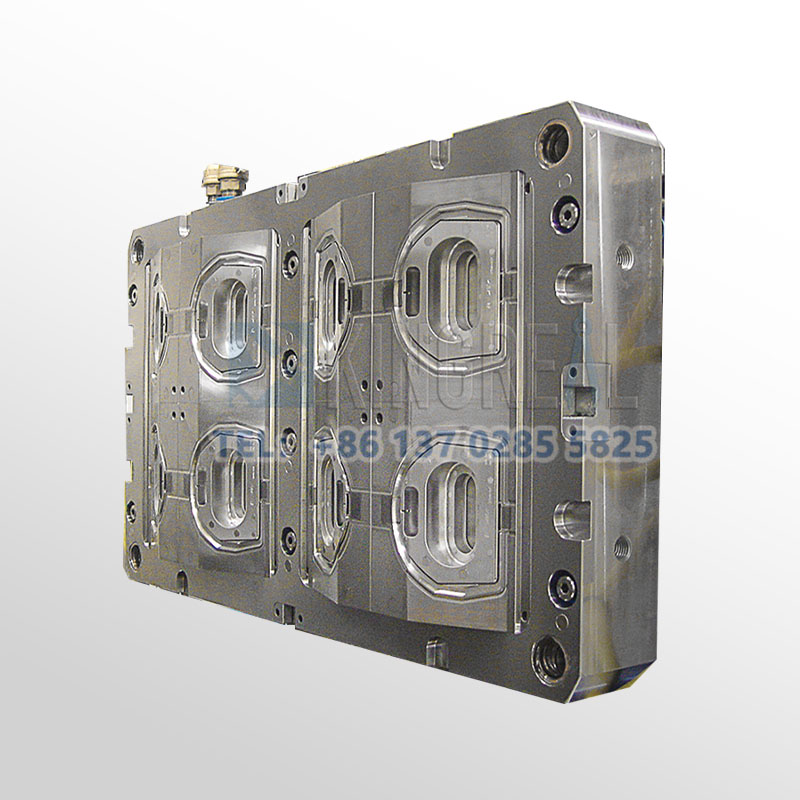

Its working principle is that two coaxial syringes perform their respective duties, and two different plastic raw materials are injected into the high-precision two-color injection molds cavity respectively. After the raw materials enter the mold cavity, they merge with each other and finally form an extensible and complementary plastic product with various characteristics. For example, in the production of some parts of automobile interior, the plastic with wear resistance can be combined with the plastic with soft touch by high-precision two-color injection molds, making the product durable and comfortable.

Advantages of high-precision two-color injection molds

(1) Complex product can be produced.

High-precision two-color injection molds has strong ability to produce products with complex structure and fine details. In the past, some complex shapes that needed multiple processes or multiple molds could be completed. Now, with the help of double injection molding, one injection can be realized, and the production cost can be effectively saved in the production process. For example, to make a home appliance shell with exquisite patterns and a variety of material combinations, the double injection molding can easily cope with it without additional complicated processing flow.

(2) Improve production efficiency

Traditional injection molding often requires multiple operations to complete the injection of different materials, while the high-precision two-color injection molds can complete the injection operation of two different materials through one injection, which greatly shortens the production time. This means that in the same time, enterprises can produce more products and significantly improve production efficiency. Taking the production of mobile phone case as an example, the production efficiency has been improved several times compared with the traditional injection mold.

(3) Broaden the scope of application

With the flexible combination ability of different materials, the double injection molding can produce products with different properties and colors. Whether it is a daily consumer product with high requirements for color matching or an industrial product with special requirements for material properties, it can meet the requirements. This makes the application range of high-precision two-color injection molds extremely wide, covering almost many industries.

(4) Scope of application of double injection molding

High-precision two-color injection molds is mainly suitable for manufacturing high-quality, complex structure and multifunctional plastic products. In the automobile manufacturing industry, many parts of the automobile interior, such as the decorative strip of the center console and the door handle, are often built with the aid of double injection molding to improve the aesthetics and comfort of the interior; In the home appliance manufacturing industry, the shell and control panel of home appliances are produced by double injection molding, which can make the appearance of products more attractive and the quality is by going up one flight of stairs; In the medical device manufacturing industry, some parts in contact with the human body can meet the needs of safety, comfort and other aspects by combining materials with different characteristics with high-precision two-color injection molds.

Design scheme of high-precision two-color injection molds

(1) Accurate material selection and equipment adaptation

According to the specific use and requirements of the product, select the appropriate materials, and determine the number of syringes needed and the injection pressure. At the same time, it is necessary to choose an adaptive double injection molding machine and position the machine tool according to the mold size to ensure the precise matching of the injector position and the mold position. For example, if the product requires strength and flexibility, you can choose the material combination of PC and TPU, and determine the appropriate double injection molding machine parameters according to the material characteristics and product size.

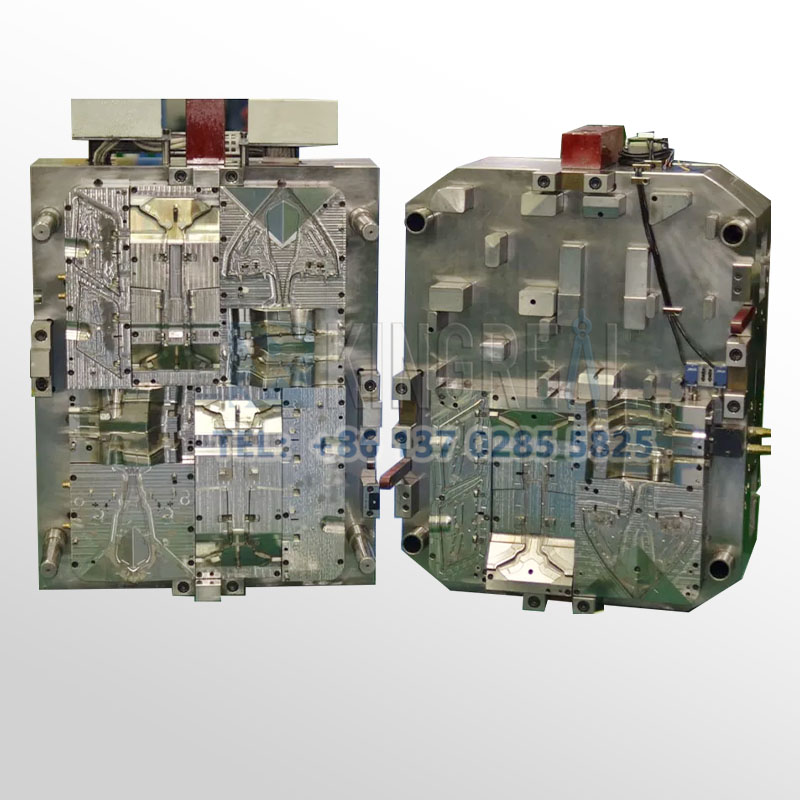

(2) Optimization of mold structural parameters

Carefully design the structure, size and aperture of the die. When the high-precision two-color injection molds work, the two materials need to enter the mold cavity at the same time and the displacement is equal, so it is necessary to ensure that the two materials can be evenly mixed in the mold cavity. For example, when designing the mold runner, the flow path and resistance of the two materials should be reasonable to ensure that they can fill the mold cavity at the same time and equally.

(3) Injection parameter setting

Refer to the injection pressure, temperature, speed and other parameters of the double injection molding machine to ensure that the properties of the final product meet the design requirements. Different materials have different requirements for injection parameters. For example, the injection temperature of PC material is usually 260-320℃, while the injection temperature of TPU material is 180-220℃, which needs to be adjusted accurately according to the actual situation.

Key points of double injection molding in product design

(1) Product appearance and function

In terms of color and pattern, double shot injection molding can inject two different colors of plastics into the same mold, which makes the plastic parts present rich and varied TINT, and even forms regular patterns or unique moire patterns, which greatly enhances the aesthetics and personalization of products. In terms of tactile and visual beauty, by skillfully combining hard plastic and soft plastic, the product not only has the firmness of hard plastic, but also has the comfortable tactile sensation of soft plastic, which enhances the tactile and visual appeal of the product. For example, in the design of mobile phone case, hard plastic is used as the main frame to ensure strength, and soft plastic is used as the outer layer to enhance hand feeling, and at the same time, with gorgeous two-color injection patterns, the mobile phone case is unique in charm.

(2) Material selection and compatibility

The matching materials of double injection molding should meet two basic conditions: adhesion compatibility and processing compatibility. There should be a certain temperature difference between the melting points of the two materials, and it is generally recommended to be at least 30 degrees to avoid mutual interference during double shot injection molding. Common material combinations are PC and TPU, PC/ABS and TPE. In terms of thickness design, the thickness of the first injection material (such as PC) is usually recommended to be 0.6-0.7mm, and the thickness of the second injection material (such as TPU or TPE) is recommended to be above 0.4 mm. For example, in the production of pen holders in the pen-making industry, PC is selected as the main material to ensure the hardness of the pen holder, and TPU is used as the outer material to improve the grip feel, and it is designed according to the appropriate thickness to make the two perfectly combined.

(3) Structural design optimization

In order to enhance the adhesion between the two materials, the contact area should be widened as much as possible or grooves and other structures should be set in the design. Taking the automobile interior decoration as an example, some small grooves are designed at the joint of the two materials, which can effectively increase the adhesion and prevent the products from delamination and cracking. The design of high-precision two-color injection molds also needs to consider the order of two injections and the rotation and exchange of the mold. The first runner of the mold should not be left on the mold after injection, and it is better to adopt hot runner or automatic shedding gate design to ensure the continuity and efficiency of production.

Application field of double injection molding

Double shot injection molding technology, with its diversified design advantages, has shown its talents in many fields. In the mobile phone industry, it is used to make mobile phone cases, buttons and other parts, making the appearance of mobile phones more beautiful and feel more comfortable; In the pen-making industry, the pen holder, pen cap and other parts are made to realize the clever collocation of color and material; In the automobile industry, we produce interior parts and decorative parts to enhance the sense of luxury and comfort inside the automobile; In the home appliance industry, components such as home appliance shells and control panels are built to improve the overall product quality and user experience.

High-precision two-color injection mold has become an indispensable force in the field of modern injection molding because of its unique structure, efficient working mode, remarkable advantages and wide application range. With the continuous development and innovation of technology, it will play a greater role in more fields and bring more surprises to the development of plastic products.