KINGREAL UNIVERSAL IND., LTD

Phone

+86-13702855825| 1 | What can KRMOLD Do? |

| 2 | Why Choose KRMOLD? |

| 3 | KRMOLD Optimization Measures |

| 4 | KRMOLD Strength |

| 5 | KRMOLD Provides You with One-stop Service |

Plastic injection molding has become an indispensable production method in modern manufacturing. Especially in the production of plastic products, the quality and design of plastic injection molds directly affect the precision and performance of the final product.

As an experienced plastic injection molds manufacturer, KRMOLD is committed to providing customers with efficient and precise plastic injection molding solutions. This article will introduce in detail the services and support that KRMOLD can provide in plastic injection molds and plastic injection molding.

1.What can KRMOLD Do?

1) Design plastic injection molds

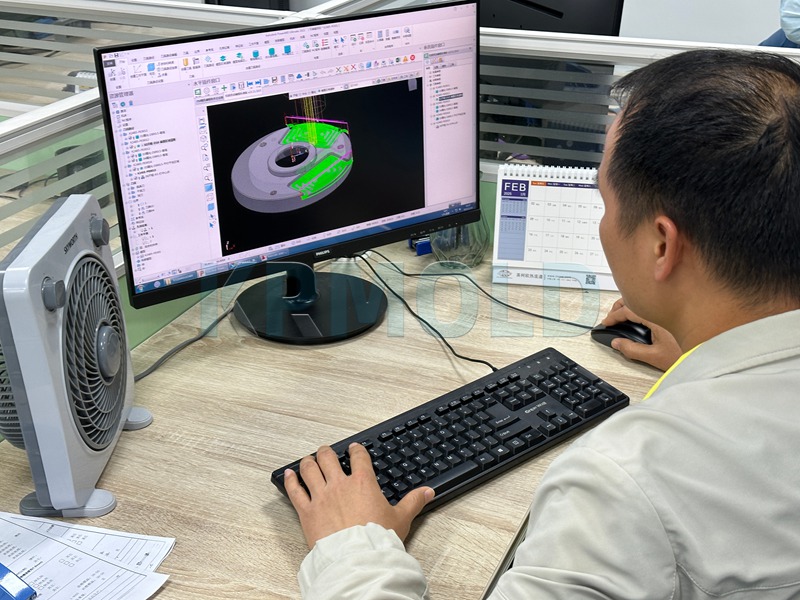

In the initial stage of plastic injection molding, design is a crucial step. KRMOLD works closely with customers to provide professional drawing optimization and design support based on samples, drawings and requirements provided by customers.

KRMOLD design team excels in the structural optimization of plastic injection molds to ensure that each injection mold can efficiently meet production needs.

Customer demand analysis: Through in-depth analysis of customer products, KRMOLD can clearly grasp the product characteristics and ensure that the design of plastic injection molds meets actual application needs.

High-efficiency mold development: During the design process, KRMOLD uses advanced 3D software for mold flow analysis to ensure uniform fluidity and pressure of plastic injection molding and reduce the proportion of defective products in subsequent production.

2) Mold opening

The mold opening process of the plastic injection molds is an indispensable part of the plastic injection molding process. KRMOLD rationally designs the structure of the plastic injection molds according to the structure and performance requirements of the product, and uses 3D laser pattern making technology to ensure the accuracy of the sample.

Mold flow analysis: During the mold opening stage, KRMOLD will conduct a detailed mold flow analysis to verify the feasibility of the plastic injection molds design, and make necessary adjustments based on the analysis results to ensure the smooth progress of plastic injection molding.

One-time sample verification: Through high-precision laser pattern making, KRMOLD can ensure that the sample meets the customer's requirements at one time, greatly improving customer satisfaction.

3) Production of plastic injection molds

After the sample is determined, KRMOLD enters the mass production stage. KRMOLD has a complete production management team and advanced equipment, which can achieve rapid delivery in a short time.

Efficient production process: Through efficient production management, KRMOLD can respond to customer needs quickly, deliver on time as fast as one week, and greatly reduce customer waiting time.

Quality control: During the production process, KRMOLD strictly controls every link to ensure the stable quality of plastic injection molded products.

4) Finished product assembly

KRMOLD provides comprehensive finished product assembly services, from incoming material inspection to final shipment, to ensure that every product meets customer requirements.

Full process management: KRMOLD assembly process includes incoming material inspection, material preparation, assembly line, finished product inspection, etc., to ensure that every detail is not overlooked.

Shipment guarantee: Through strict quality inspection, KRMOLD can ensure that high-quality injection molded products are delivered to customers on time.

2.Why Choose KRMOLD?

KRMOLD is committed to solving various problems encountered by customers in the plastic injection molding process to ensure the smooth production.

1) Plastic injection molds selection

Many customers may face the problem of not being able to grasp the characteristics of the product when choosing plastic injection molds. KRMOLD provides professional plastic injection molds selection suggestions through in-depth analysis of product requirements to ensure that customers choose the most suitable plastic injection molds.

2) Mass processing

In mass processing, the stability of injection quality is crucial. KRMOLD optimizes the production process and improves the quality of plastic injection molding to ensure that each batch of products can meet customer standards.

3) Finished product spraying

Many customers often encounter problems after plastic injection molding that the appearance does not meet the requirements. KRMOLD professional team can provide high-quality finished product spraying services to make the product appearance meet the expected effect.

4) Timely delivery

In modern manufacturing, the timeliness of delivery directly affects the customer's production plan. KRMOLD ensures that it can deliver on time and in quantity through efficient production management to meet the urgent needs of customers.

3.KRMOLD Optimization Measures

In order to improve the efficiency and quality of plastic injection molding, KRMOLD has taken a series of optimization measures.

1) Material pretreatment

Different materials have different water absorption, and some materials need to be dried before processing. KRMOLD will pre-treat the material according to its characteristics to reduce the proportion of defective products during the plastic injection molding process.

2) Plastic injection molding equipment status maintenance

High-precision plastic injection molding equipment needs to be kept in good working condition. KRMOLD regularly maintains the equipment to ensure the tacit cooperation of each system and reduce the defective rate during product production.

3) Mold maintenance

Plastic injection mold maintenance is very important. KRMOLD follows a series of maintenance specifications, including keeping the mold clean, avoiding wear, timely replacing wear parts, and maintaining lubrication to ensure that the mold is always in an efficient working state.

4) Mold design optimization

During the development process, KRMOLD will design the plastic injection molds according to the basic properties of the applied raw materials. We focus on the flow direction of the melt in the mold cavity, pressure uniformity, and gas emission conditions to reduce the difficulty of plastic injection molding and improve production efficiency.

4.KRMOLD Strength

KRMOLD has advanced production equipment and rich industry experience, which can accelerate the development of new products and ensure the continuous and stable plastic injection molding production.

KRMOLD has several professional workshops, including CNC workshop, EDM workshop, raw material workshop, design workshop, polishing workshop, rough processing workshop and flying mold workshop, etc., to ensure that the manufacturing of each plastic injection mold has gone through strict multi-process.

5.KRMOLD Provides You with One-stop Service

KRMOLD goal is to reduce defective products and reduce costs for customers. KRMOLD can provide customers with one-stop service, from design to production, to trial mold modification, to ensure that every link can meet customer requirements.

Trial mold modification: If the sample does not meet the parameter requirements, KRMOLD will continue to modify it until the customer is satisfied.

Multiple quality inspection equipment: Through multiple quality inspection equipment, KRMOLD can conduct comprehensive quality control of the product to ensure that every product of plastic injection molding can meet high standards.

In short, KRMOLD has rich experience and strong strength in plastic injection molds and plastic injection molding. KRMOLD provides customers with high-quality plastic injection molding solutions through professional design, efficient production and strict quality control.

Whether it is the automotive industry, medical industry or electronics industry, KRMOLD will go all out to help customers achieve perfect plastic injection molding.