KINGREAL UNIVERSAL IND., LTD

Phone

+86-13702855825What is auto door trim molding technology?

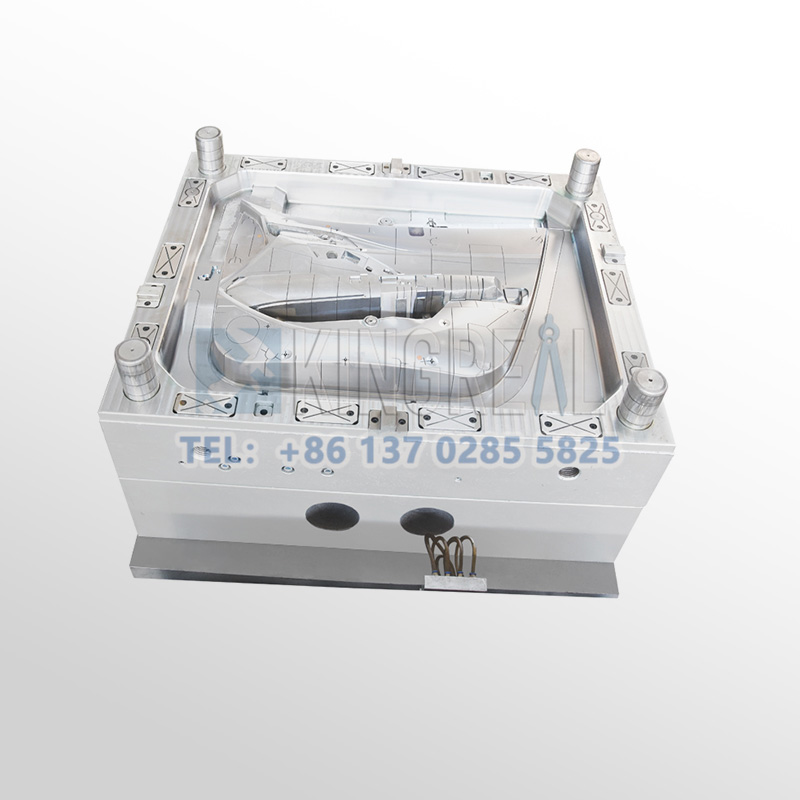

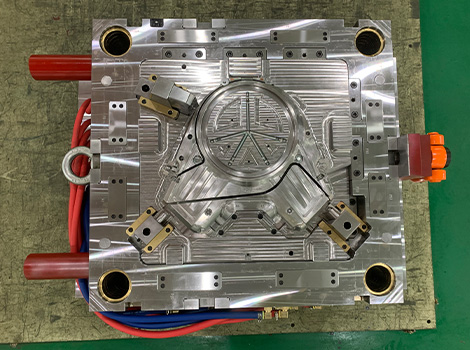

Auto door trim molding technologyproduces the desired part or product by shaping the molten material into a cavity. The geometry of the cavity outlines the three-dimensional shape of the designed product. High pressure is usually applied during the injection process to promote material flow and maintain density after the material solidifies.

Types of automotive exterior trim molds

It is crucial to choose the right type of automotive door panels molds and tools for your project. The automotive exterior trim molds affect the production speed, total cost, and the quality of the final product. Different automotive door panels molds and tools are divided into four major categories:

✦ Based on Feeding System

The first category here is the classification based on the feed or runner system. The feed system is a series of channels, including gates, sprues, and runners. The channel guides the molten plastic from the nozzle to the desired part of the cavity. Automotive door panels molds and tools under this category include:

Hot runner automotive door panels molds and tools

The hot runner system uses runners that have been heated internally or externally by coils or rods. This type of feed system is enclosed within a fixed manifold plate. They remain permanently within the plate, preventing them from being ejected along with the part.

As a result, the molded part will be clean without any additional plastic waste. This reduces waste generation and eliminates any additional processes to remove or recycle runners. Additionally, there is usually no need for regrinding or post-processing of hot runner automotive exterior trim molds. As a result, the production process is much faster. When combined with multi-cavity molds, this type of automotive door panels molds and tools help to process a large number of complex and delicate shapes.

However, there are also some disadvantages to using a hot runner system. The system is usually expensive to install and heat. Maintenance is also expensive and requires skilled expertise to oversee the auto door trim molding process. Because the runners are hidden, it can be difficult to ensure that they are clean and free of plastic residue from previous production processes. This is often a big problem when dealing with color changes. Finally, internally heated hot runners can have sticking issues, especially when dealing with heat-sensitive materials.

Cold runner automotive exterior trim molds

Cold runner systems use unheated runners to deliver molten plastic to the cavity. Unlike hot runner automotive door panels molds and tools, cold runner auto door trim moldings are exposed because the operator cuts them into the automotive exterior trim molds. You need to make a new runner system for each molding cycle. Depending on the type of plate used, you may be able to connect or separate the molded part and runner system upon demolding.

These automotive door panels molds and tools are easier to clean and maintain. They also ensure faster and easier changes in materials and colors. In addition, you can easily integrate auto door trim molding design iterations due to rapidly changing gate and runner locations. While hot runner automotive exterior trim molds with internal heating have difficulty handling certain materials, cold runners can handle a wide range of materials.

However, mold runner automotive exterior trim molds generate a lot of scrap material with each cycle. Most manufacturers typically discard the runners after use. Although some manufacturing companies have found ways to regrind and reprocess these runners for reuse, doing so can lengthen the overall manufacturing process. Regrinding runners also often changes their physical properties, affecting the final product. As a result, it may be different from the original design.

Insulated runner automotive exterior trim molds

These tools look more like traditional cold runner auto door trim moldings. However, they use cartridge heaters or other forms of heating to form a surrounding layer of molten plastic. Therefore, they form an insulating "knockout" to create a similar effect to hot runner systems.

Manufacturers often choose this method because it does not require a temperature controller, making it less expensive than hot runners. In addition, it allows for easy and quick changes in materials and colors. However, adiabatic runner automotive door panels molds and tools are not suitable for all materials. They are generally not suitable for demanding engineering-grade plastics.

✦ Based on the number of cavities

This category contains three different auto door trim molding designs, each capable of producing a specific number of parts per molding cycle, including:

Single-cavity automotive door panels molds and tools

Single-cavity automotive exterior trim molds produce one part per injection cycle. While it may be a slower auto door trim molding to produce, its mold costs are lower than other options. Due to the relatively low cost, small batch production is often more affordable.

Single-cavity automotive door panels molds and tools also provide better control over the molding process. Manufacturers often use multiple single-cavity tools to ensure continuous operation of the process, even if one mold fails.

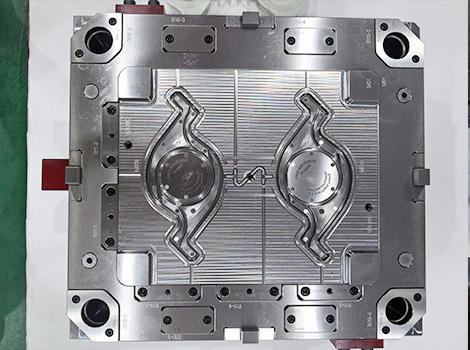

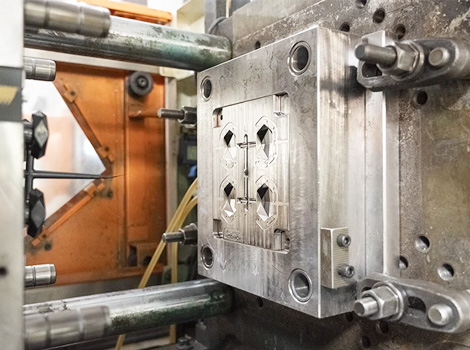

Multi-cavity auto door trim moldings

Multi-cavity automotive door panels molds and tools are designed so that they can produce multiple identical parts in one injection cycle. The initial cost of an auto door trim molding is usually higher than a single-cavity mold. However, this auto door trim molding is more suitable for large-scale production because each mold can produce multiple parts at the same time, with faster production and lower per-part costs.

Family Injection automotive exterior trim molds

Family automotive door panels molds and tools also have multiple cavities like multi-cavity automotive exterior trim molds. However, they are best used to make multiple parts in a single cycle. For example, a manufacturer can use one family auto door trim molding to create one right component and one left component iteration. On the other hand, a simple multi-cavity auto door trim molding can only produce one iteration in a single cycle.

Although family automotive exterior trim molds are expensive, they can usually reduce overall production costs. This is because one family auto door trim molding can be used for a variety of components. It also saves a lot of time and operating costs. However, you must note that these automotive door panels molds and tools types are only suitable for parts made of the same material and color. For parts that require different material and color variations, you will need separate automotive exterior trim molds.

✦ Template Based

Another important category in auto door trim molding is based on the number of plates that make up the entire mold cavity necessary for the production of the part. This category includes the following mold designs.

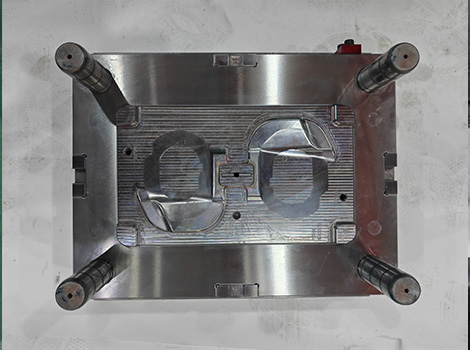

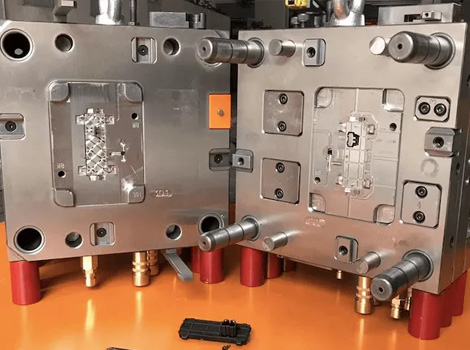

Two-Plate automotive door panels molds and tools

This is the most common auto door trim molding design in this category because of its low mold cost. Two-plate automotive exterior trim molds feature a parting line where the core plate and cavity plate meet. In this design, the gates, runners, and parting lines must be aligned. While it is compatible with any runner system, it works best with single-cavity automotive exterior trim molds.

Three-plate auto door trim molding

The additional plate (stripper plate) of this mold gives it two parting lines. It is placed between the cavity and core plates, automatically separating the runner system from the molded part. This ensures faster production because there is no need to manually separate or recycle the runner system.

However, the extra plate increases the overall tooling cost because the cuts must be precise to match the other two plates. Note that three-plate automotive door panels molds and tools are only used for cold runner systems to separate the runners. Hot runner auto door trim molding systems do not require this type of mold.

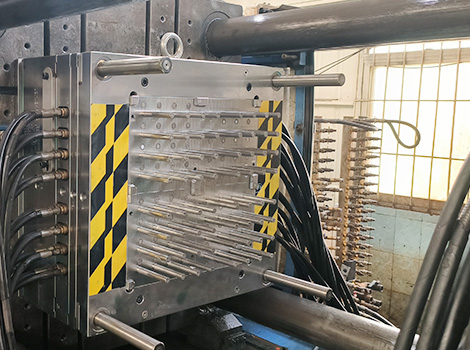

Stacked automotive exterior trim molds

Stack automotive door panels molds and tools have multiple platens in parallel. There can be two, three, or four layers of platens to increase process efficiency. Stack automotive exterior trim molds require less clamping tonnage per cycle. The upfront cost of the auto door trim molding is higher because it takes longer to build. However, the lower the clamping tonnage requirement, the lower the operating cost. The mold can even be designed to hold multiple materials at the same time.

✦ Swing-based automotive door panels molds and tools

These are the best automotive exterior trim molds for making threaded holes within plastic parts. They are automated automotive door panels molds and tools with a drive system that consists of:

Rack and pinion

Electric motor

Hydraulic motor

This unique auto door trim molding uses a rotary drive system to create threaded components such as bottle caps, nuts and bolts, automotive parts, shampoo bottles, and cosmetic packaging. These components are usually difficult to auto door trim molding based on the draft angle.

Hence, a swing-open auto door trim molding helps in disassembly without damaging the threads. Undercut auto door trim molding is also crucial here as it allows for the removal of damaged complex parts. It operates at high speeds, reduces cycle time, and ensures high-volume production.

FAQ:

What materials can be used for auto door trim molding?

Thermoplastics, thermosets, and elastomers are the main automotive exterior trim molds materials. However, metals and alloys can also be molded with the proper equipment and tools.

● ABS

● Polycarbonate

● Nylon

● Epoxy

● Phenolic

● Silicone rubber and many more.