KINGREAL UNIVERSAL IND., LTD

Phone

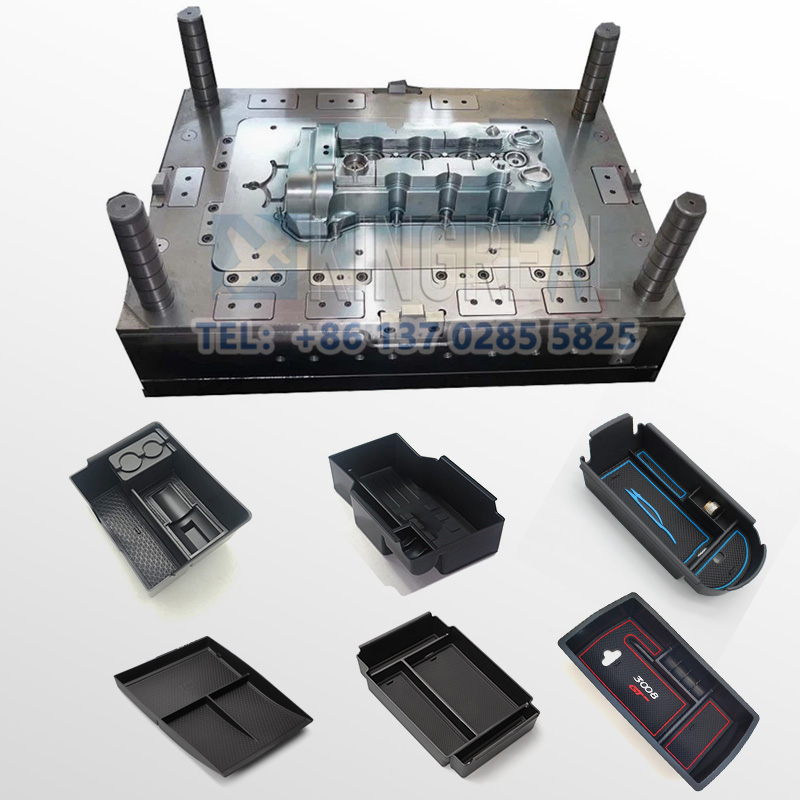

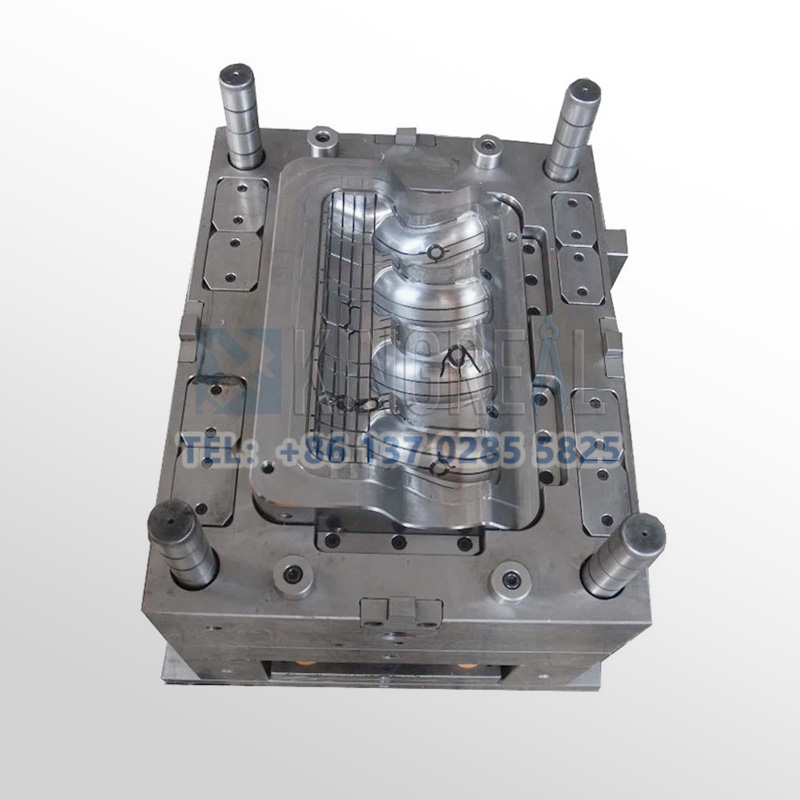

+86-13702855825In the manufacture of car glove box injection molds, it is crucial to choose the right material. The material of the automotive glove box injection mould not only affects the production efficiency, but also directly relates to the quality of the final product.

In this article, KRMOLD will discuss with you the selection basis of central glove box injection mold materials, including product requirements, mold structure, processing technology and cost factors, etc., aiming to provide guidance for the manufacture of high-quality automotive glove box injection mould.

| 1 | Requirements for Car gGlove Box Injection Mold Materials |

| 2 | Materials of Central Glove Box Injection Mold |

| 3 | Methods for Selecting Suitable Materials for Car Glove Box Injection Molds |

1.Requirements for Car gGlove Box Injection Mold Materials

(1) Easy to process. Central glove box injection mold parts are mostly made of metal materials, and some of the structural shapes are very complex. In order to shorten the production cycle and improve efficiency, the automotive glove box injection mould material is required to be easy to process into the shape and precision required by the drawing.

(2) Good wear resistance. The glossiness and precision of the plastic surface are directly related to the wear resistance of the car glove box injection mold cavity surface. In particular, when glass fiber, inorganic fillers and certain pigments are added to some plastics, they flow at high speed in the flow channel and central glove box injection mold cavity together with the plastic melt, causing great friction on the cavity surface. If the material is not wear-resistant, it will soon wear out and damage the quality of the plastic part.

(3) High corrosion resistance. Many resins and additives have a corrosive effect on the cavity surface. This corrosion causes the metal on the cavity surface to dissolve and peel off, the surface condition deteriorates, and the quality of the plastic part deteriorates. Therefore, it is best to use corrosion-resistant steel, or chrome-plated or cymbal-nickel-plated the cavity surface.

(4) Good dimensional stability. During automotive glove box injection moulding, the temperature of the central glove box injection mold cavity must reach above 300°C. For this reason, it is best to use tool steel (heat-treated steel) that has been properly tempered. Otherwise, it will cause changes in the material micro-structure, resulting in changes in the automotive glove box injection mould size.

(5) Small impact of heat treatment. In order to improve hardness and wear resistance, the car glove box injection mold is generally heat treated, but this treatment should make its size change very small. Therefore, it is best to use pre-hardened steel that can be cut.

(6) Good polishing performance. Plastic parts are usually required to have good gloss and surface state, so the roughness of the cavity surface is required to be very small. In this way, the cavity surface must be surface processed, such as polishing, grinding, etc. Therefore, the selected steel should not contain rough impurities and pores.

2.Materials of Central Glove Box Injection Mold

(1) Tool steel: Tool steel is one of the most commonly used automotive glove box injection mould materials, with high hardness, wear resistance and corrosion resistance. Common tool steels include P20, H13, S136, etc. P20 steel has good cutting performance and wear resistance, and is suitable for medium and low pressure central glove box injection mold making; H13 steel has higher hardness and heat resistance, and is suitable for high pressure car glove box injection mold making; S136 steel has excellent corrosion resistance and wear resistance, and is suitable for high-demand automotive glove box injection mould making. The selection of tool steel is determined by factors such as the use conditions, product requirements and expected life of the car glove box injection mold.

(2) Stainless steel: Stainless steel is a common central glove box injection mold material with good corrosion resistance and oxidation resistance. Common stainless steel materials include SUS420, SUS304, etc. Stainless steel is suitable for automotive glove box injection mould making in humid environments or where high hygiene is required, such as food containers, medical devices, etc.

(3) Aluminum alloy: Aluminum alloy has low density, excellent thermal conductivity and processing performance, and is suitable for making large injection molds or injection molds with complex structures. The selection of aluminum alloy depends on the size of the automotive glove box injection mould, structural requirements and material characteristics.

(4) Copper alloy: Copper alloy has excellent thermal conductivity and electrical conductivity, and is suitable for making high-demand car glove box injection molds, such as electronic product housings, conductive parts, etc. The selection of copper alloy is determined according to factors such as the thermal conductivity requirements, mechanical properties and corrosion resistance of the automotive glove box injection mould.

(5) Polymer materials: Polymer materials include nylon, polyimide, polyamide, etc., which have good wear resistance, corrosion resistance and dimensional stability. Polymer materials are suitable for making central glove box injection molds with special needs, such as high-temperature car glove box injection molds, precision molds, etc.

(6) Other special materials: In addition to the above common material selections, other special materials such as ceramics, composite materials, etc. can also be selected for the production of automotive glove box injection mould according to different needs and special requirements. These special materials have special properties and advantages and are widely used in specific fields.

When selecting the material for the car glove box injection mold, factors such as product requirements, cost, manufacturing process and use environment need to be considered. Different materials have their specific advantages and disadvantages and scope of application. It is necessary to comprehensively consider various factors and select the most suitable material to make the central glove box injection mold to meet the requirements of the product and optimize production efficiency.

Automotive glove box injection mould are divided into soft molds and hard molds in terms of materials. Soft molds are generally made of P-20 pre-hardened steel, and some backward places use carbon steel above No. 45. The production capacity is generally around 500,000 times; hard molds are made of hot-working mold steels such as H-13 (chrome steel) or 420 (stainless steel). They need to undergo heat treatment processing technology. The material and processing costs are more than doubled, and the production capacity is more than one million times.

3.Methods for Selecting Suitable Materials for Car Glove Box Injection Molds

(1)Product requirements

Precision requirements: For products with high precision requirements, such as precision electronic component housings, materials with good dimensional stability and small heat treatment deformation, such as Cr12MoV, etc., should be selected.

Appearance quality: If the product surface requirements are high, such as mirror effect, P20 steel can be selected, and its good mirror polishing performance can meet the requirements.

Production requirements: Automotive glove box injection mould for mass production should use high-strength and high-wear-resistant materials, such as H13 steel; small-batch production can consider low-cost 45 steel, etc.

(2)Mold structure

Complexity: For complex mold structures, to ensure processing accuracy and molding quality, easy-to-process aluminum alloys or pre-hardened steel P20 can be selected.

Size: Large molds require materials with good strength and toughness, and H13 steel is more suitable; small molds have relatively low material strength requirements, and Cr12MoV can be selected.

(3)Processing technology

Cutting performance: The cutting performance of the material affects the processing efficiency and cost. For example, P20 steel has good cutting performance, which can reduce the processing difficulty and cost.

Heat treatment process: For some materials such as H13 steel, the heat treatment process is relatively complex and requires professional equipment and technology. It is necessary to comprehensively consider the processing conditions.

(4)Cost factors

Material cost: Cemented carbide has high cost, while carbon steel has low cost, and it needs to be selected according to the production budget.

Comprehensive cost: The service life of the central glove box injection mold and maintenance cost should also be considered. For example, although the unit price of H13 steel is high, it has a long service life, and the comprehensive cost may be more cost-effective.