KINGREAL UNIVERSAL IND., LTD

Phone

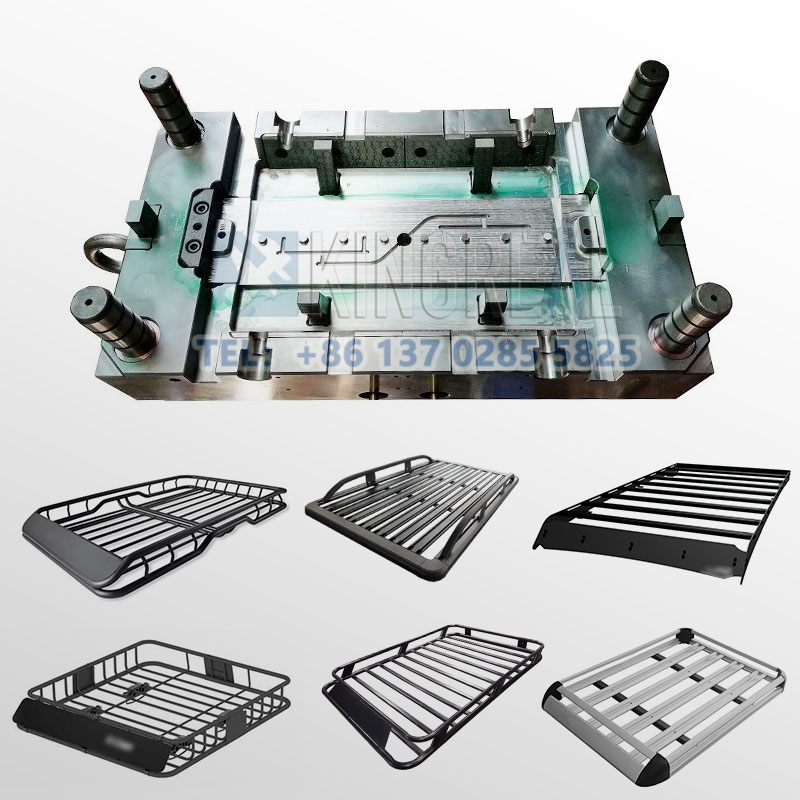

+86-13702855825In the field of modern industrial production, plastic roof rack injection mold, as the core equipment of automotive roof rack injection molding, occupies a decisive position. By virtue of its unique working principle, it accurately injects molten materials into specific cavities, and after cooling and solidification, it shapes all kinds of products with required shapes, laying the foundation for product manufacturing in many industries.

| 1 | Remarkable advantages of automotive roof rack injection mold |

| 2 | Concrete embodiment of the advantages of plastic roof rack injection mold |

| 3 | Outstanding characteristics of plastic roof rack injection molding |

1. Remarkable advantages of automotive roof rack injection mold

(1) Accurate design

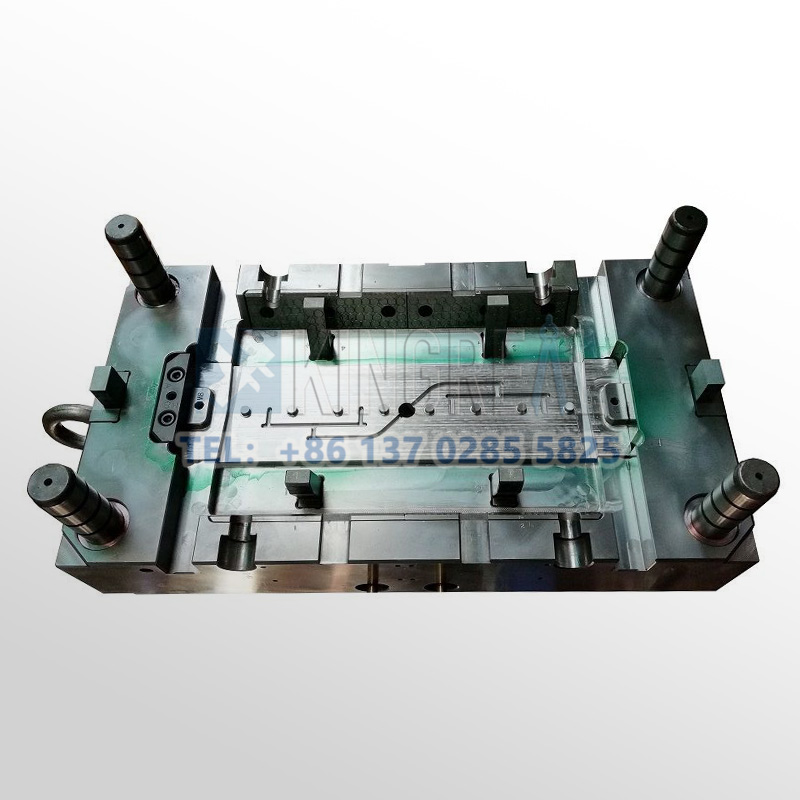

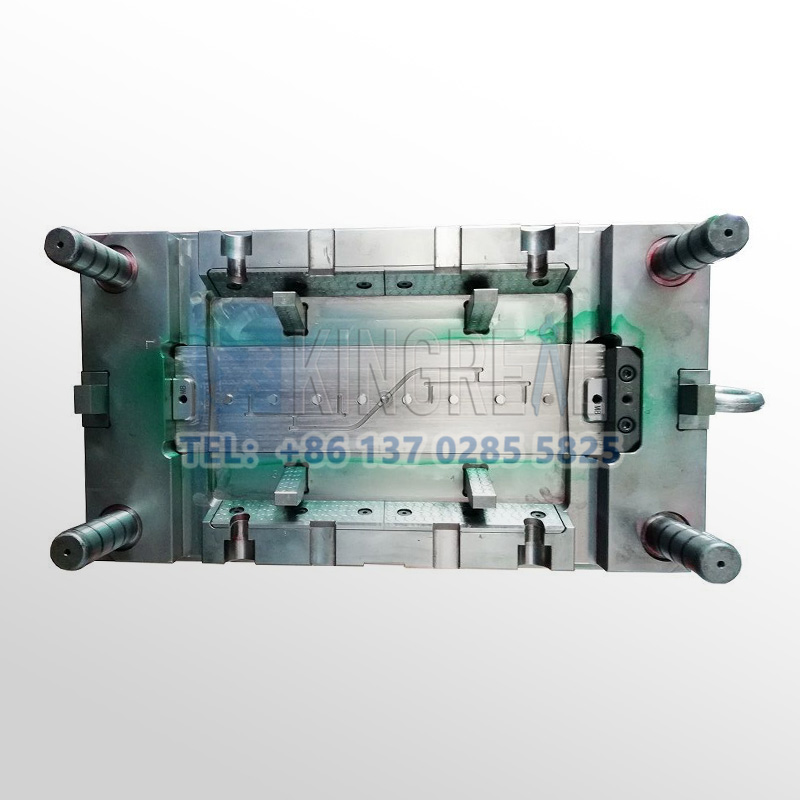

From the design dimension, the injection molded plastic auto parts stands out with its remarkable high precision and accuracy. Based on detailed product drawings and strict requirements, designers carry out meticulous design and all-round optimization of automotive roof rack injection molds. In this process, every detail of the injection molded plastic auto parts is repeatedly carved to ensure the best condition. This extremely accurate design not only provides a solid guarantee for product quality, but also greatly improves production efficiency and stability, making products achieve a double leap in quality and quantity.

(2) Flexible structure

The automotive roof rack injection mold shows excellent flexibility in structure. Faced with diversified products and complex and changeable production process requirements, the injection molded plastic auto parts can skillfully adjust its own structure and parameters, and easily meet the challenges of various complex shapes and sizes. The diversity of this structure has opened up a vast space for the production of plastic products, continuously satisfying the ever-changing diversified needs of the market, and has become the key driving force for the innovation and development of plastic products.

(3) Economical and efficient

Economy is an outstanding advantage that cannot be ignored in plastic roof rack injection mold. While strictly observing the bottom line of product quality, through reasonable selection of materials and clever use of advanced manufacturing technology, the injection molded plastic auto parts can significantly improve the product output without excessively increasing the cost. This feature effectively reduces the production cost of enterprises, helps enterprises to successfully expand profit space and enhance market competitiveness in the fierce competition market.

(4) Technological innovation

With the rapid development and continuous innovation of science and technology, major breakthroughs have been made in the design concept and manufacturing technology of automotive roof rack injection molds. The extensive application of new materials and the deep integration of advanced technologies, such as intelligent sensing technology and digital manufacturing technology, further optimize the performance of the injection molded plastic auto parts and greatly extend its service life. These innovations have injected new vitality into the development of enterprises and helped enterprises seize the opportunities in the wave of industry changes.

2.Concrete embodiment of the advantages of plastic roof rack injection mold

(1) High cost performance

Compared with the traditional mold manufacturing process, injection molded plastic auto parts manufacturing has obvious cost advantages, and its design process is more streamlined and efficient, which can realize mass production in a short time. At the same time, the manufacturing of plastic roof rack injection molds is excellent in quality and practicality, and the products are durable and reliable in performance. Considering the cost and performance factors, the cost-effective advantage of injection molded plastic auto parts is fully demonstrated, which has become the first choice for many enterprises in mold selection.

(2) High quality assurance

In the manufacturing process of injection molded plastic auto parts, the details are almost strictly controlled, and the reasonable collocation of mold materials is paid close attention to from the source. In the production process, the injection mold is manufactured to ensure that there is no internal stress, and the mold structure is compact and the overall stability is excellent, which has created a very high product quality. This high-quality product output has strongly supported the product quality upgrade of downstream enterprises and won wide market recognition.

(3) enrich the design options

Injection molded plastic auto parts manufacturing adopts a unique mode of step-by-step design and disassembly, which fully combines customer needs in the early stage and provides various types of automotive roof rack injection molds for selection. This enables users to have rich autonomy in the design process and can choose the appropriate mold type and shape according to their own needs; Manufacturers can also tailor plastic roof rack injection molds according to customers' individual needs. Compared with traditional hard molds, automotive roof rack injection mold manufacturing is more flexible and changeable in design, which fully meets the diversified design needs of the market.

(4) Exquisite appearance

Injection molded plastic auto parts manufacturing keeps up with the aesthetic trend of the times, and skillfully adds decorative elements such as patterns and colors in the injection process, which endows the original monotonous mold products with unique charm. In particular, the use of high-grade decorations such as gold patterns makes the appearance of plastic roof rack injection mold products more exquisite, meets some market demands with high requirements on product appearance, and further expands the application field of injection molded plastic auto parts.

3.Outstanding characteristics of plastic roof rack injection molding

(1) Complex parts molding

Automotive roof rack injection molding technology has a strong ability to handle complex parts and can realize highly complex part design. By carefully designing the injection molded plastic auto parts and accurately controlling the molding process, this technology not only ensures the consistency of parts molding, but also gives enterprises the ability to manufacture millions of almost identical parts. In the process of mass automotive roof rack injection molding, the efficiency potential of mass plastic roof rack injection molding should be fully considered and tapped in part design to ensure that high-quality production can be achieved without sacrificing the complexity of parts and meet the large-scale demand of complex parts in various industries.

(2) Efficient and rapid production

As the most common and efficient automotive roof rack injection molding method, automotive roof rack injection molding has unparalleled speed advantage. Compared with other molding methods, the process speed is faster and the production output rate is extremely high. Although the molding speed is affected by the complexity and size of the mold, each molding cycle usually takes only 15-120 seconds. Such a short cycle interval makes it possible to produce more injection-molded parts in the same production time, which greatly improves the production efficiency and provides a strong guarantee for enterprises to respond to market demand quickly.

(3) Strong product consistency

When producing high-yield and complex plastic parts, it is very important to ensure the consistency and repeatability of the process, which is directly related to whether the products can meet the strict tolerance design requirements. The continuous use of the same injection molded plastic auto parts in the automotive roof rack injection molding process, relying on the practical experience of continuous improvement of plastic roof rack injection molding machines and the application of advanced technology, provides a solid guarantee for the consistency of product quality. Every produced part can maintain a highly consistent quality level, effectively reducing the fluctuation of product quality and improving the overall product quality stability of the enterprise.

(4) Manufacturing of precision products

Modern high-speed automotive roof rack injection molding equipment can realize the production of large-scale precision injection molded plastic auto parts after proper maintenance. For the production of injection molded plastic auto parts such as connectors and gears, plastic roof rack injection molding technology is the best choice, and its tolerance accuracy can reach 0.0002 inch. This high-precision manufacturing capability meets the stringent requirements of high-end industries such as electronics and automobiles for precision injection molded plastic auto parts, and promotes the improvement of product performance and technological progress in related industries.

(5) Shorten the development cycle

The team of automotive roof rack injection mold engineers has diverse professional skills, which can help original equipment manufacturers (OEMs) significantly shorten product development time. By optimizing the mold design and manufacturing process, the production cycle is greatly shortened, and the defect-free products can be introduced to the market faster. This advantage has become a key factor for enterprises to win the first opportunity in the fierce competitive market environment, which is helpful for enterprises to respond quickly to market changes and enhance market competitiveness.