KINGREAL UNIVERSAL IND., LTD

Phone

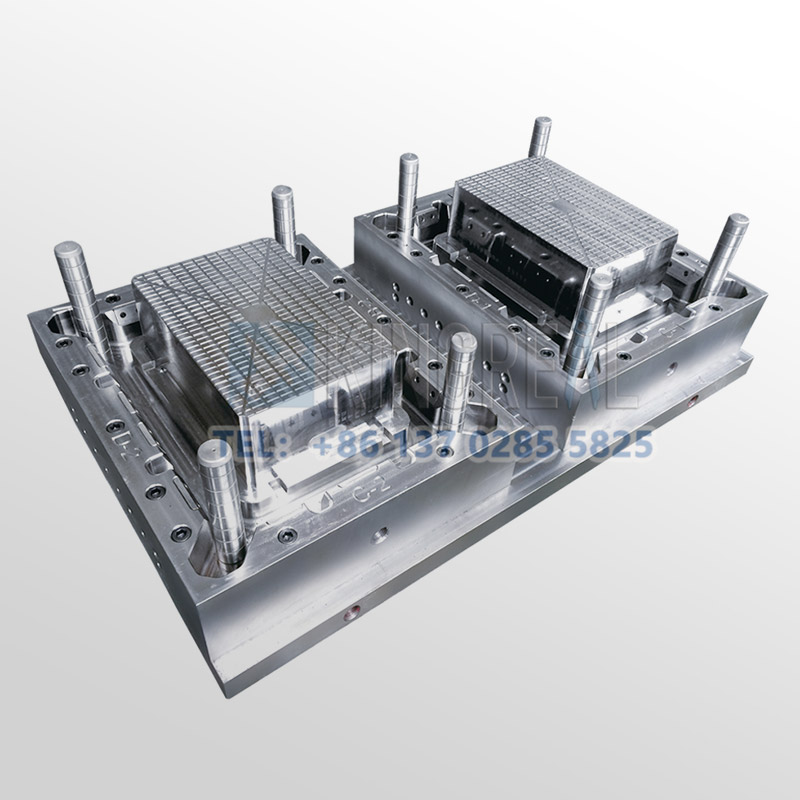

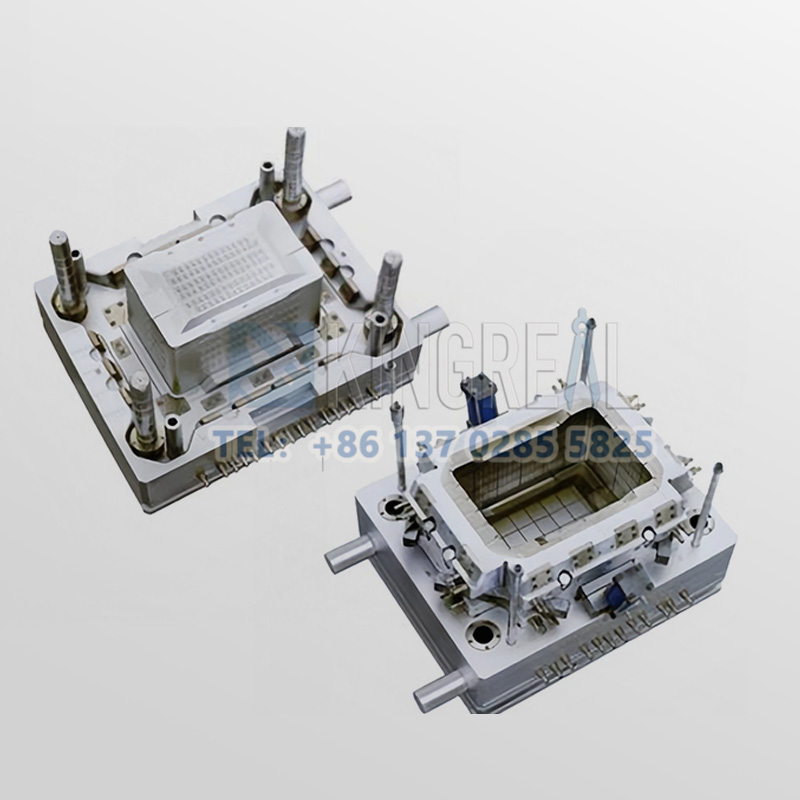

+86-13702855825Plastic injection mold is an important process equipment for the production of various industrial products. With the rapid development of the plastic industry, the promotion and application of plastic products in many fields such as aviation, aerospace, electronics, machinery, ships and automobiles, the requirements for injection molding molds are increasing day by day. In the modern manufacturing industry, the production of almost all product components depends on injection molded parts forming, therefore, the injection molding mold industry as an important part of the national high-tech industry, has become an important and valuable technical resources.

Application areas of plastic injection molding

The wide application of injection molding mold technology covers a number of industries, which can be divided into the following 11 types, and the specific parameter requirements and focuses of each field are different:

1. The automotive industry

Plastic injection molding can be used to produce automotive interior parts (such as instrument panels, door panels, seats, etc.), external decorative parts (such as bumpers, lampshades, car signs, etc.) and functional parts (such as water tanks, pipes, fuel tanks, etc.). With the rapid development of new energy vehicles, plastic injection molding also plays an important role in the application of lightweight materials.

2. Home appliance industry

Injection molded parts is widely used to manufacture the shell and internal parts of household appliances, such as the shell and internal structural parts of TV sets, refrigerators, washing machines, air conditioners, etc. These plastic products are not only beautiful, but also have good durability and insulation properties.

3. Medical device industry

Injection molding mold is widely used in the production of disposable medical devices (such as syringes, infusion sets, blood collection devices, etc.) and medical device enclosures. These products need to meet stringent hygiene and safety standards, and plastic injection molding technology can provide high-precision, high-cleanliness manufacturing solutions.

4. Electronic device industry

In the production of electronic products housing, injection molding mold plays a key role, such as mobile phones, computer accessories, keyboards and MP3 players. The production of electronic components mainly uses plastic injection molding technology, including mold design, material selection and processing methods. These products require a refined appearance and a high degree of structural strength, while injection molded parts also provides excellent electromagnetic shielding and insulation properties.

5. Packaging industry

Plastic injection mold is widely used in the production of various types of packaging containers, such as bottles, bottle caps and food packaging boxes. For example, plastic bottles for beverages and dairy products, as well as caps for cosmetics and pharmaceuticals, are manufactured by injection molded parts. These packaging products must meet food safety, moisture resistance and beat resistance standards, injection molding mold can provide high precision, low cost production solutions.

6. Toy and model industry

Injection molding mold can produce children's toys and models in various shapes and colors to meet the diverse needs of the market. At present, it is mainly used in automobile, electronics, machinery and construction industries. These products are generally required to look beautiful, durable and safe and non-toxic, plastic injection molding technology can provide high-quality production solutions for these products.

7. Building materials industry

Injection molded parts is also widely used in the manufacture of building materials, such as door and window frames, various pipes and decorations. Plastic pipe is mainly used for indoor decoration and outdoor laying in buildings, with light weight, high strength, corrosion resistance, not easy to deformation and other advantages.

8. Industrial parts

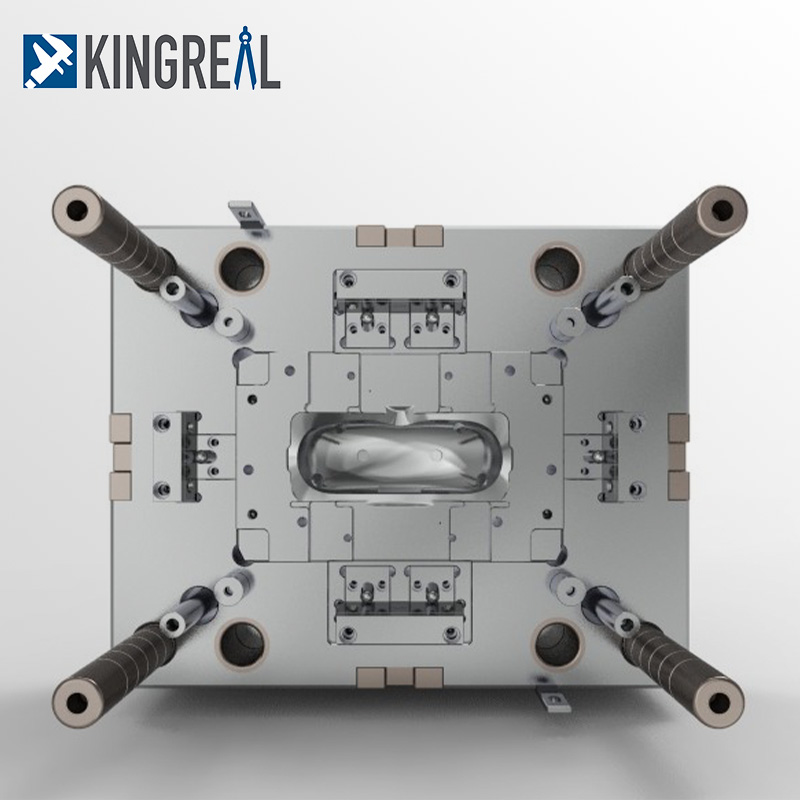

Injection molding mold enables the production of a wide range of industrial parts such as gears, valves and connecting parts, which are widely used in mechanical equipment and manufacturing requires high precision and high quality mechanical properties.

9. Aerospace industry

Injection molded parts has been applied to the manufacture of structurally precise, precision demanding parts such as aircraft interiors, sensor housings and various connectors. In order to meet the standards of high strength, high temperature resistance and lightweight, injection molding mold provides an effective solution for high-quality manufacturing.

10. Furniture industry

Injection molded parts plays an important role in furniture manufacturing due to its unique advantages in terms of durability, aesthetics and design innovation. This technology helps to combine function with style, such as chair bases, desk legs and office furniture combinations.

11. Farm tools and equipment

Injection molding mold has transformed the agricultural industry, providing robust, weather-resistant components essential to modern agriculture. For example, instrument panel housings, knobs and levers for tractors and harvesters, sprinkler heads and connectors for irrigation systems are all produced efficiently through injection molded parts.

Advantages of plastic injection molding

Injection molding mold shows numerous advantages in mass production, making it an integral part of modern manufacturing. The following are the main advantages of plastic injection molding:

Efficient production: Injection molded parts is praised for its fast manufacturing cycle, with each production cycle typically between 30 seconds and 1 minute.

- High precision: Through injection molding technology, products with complex shapes and precise dimensions can be manufactured.

- Complex parts: This method enables the design of complex shapes and structures, especially thin-shell parts for various types of equipment.

- Material versatility: Injection molding mold can handle a variety of molds and thermosetting materials, including PS, ABS, PA, PP, PE and PVC.

- Low waste: The process is designed to significantly reduce material loss, helping to reduce costs and bring benefits to the environment.

- Mass production: Once the injection molded parts is created and configured successfully, the injection molding machine can produce large quantities of parts in a short time to meet production needs.

FAQ

1. What is the plastic injection molding process?

Injection molding is a plastic manufacturing process in which heated and melted plastic is injected into a mold and the desired product is obtained through steps such as clamping, injection, pressure holding, cooling, mold opening and ejection.

2. What are the advantages of injection molding mold?

Injection molding in mass production shows a number of advantages such as efficient production, high precision, complex parts, material versatility, low waste and mass production.

3. What types of materials can be used for molding?

Injection molded parts is suitable for a variety of plastic materials, including but not limited to ABS, PC, PA, POM, etc., in addition to PMMA, PP, PBT, PPSU, PEEK, PEI and other materials can be used for this process.

4. Which industries benefit the most from injection molded parts?

Due to its advantages of high precision, low cost and wide applicability, injection molding plays an important role in many industries, especially in the automotive, household appliances, electronic products and medical device industries.