KINGREAL UNIVERSAL IND., LTD

Phone

+86-13702855825Two-color injection molding is a technology of injecting two different materials into the same mold at the same time or separately. This process can save time and cost, because one mold can complete the injection of two different materials without additional steps and costs, such as assembly or fitter. In addition, by using two-shot injection molding, more complex parts or products can be produced because they can inject different materials into the same double shot injection molds. In this article, KRMOLD will introduce more information related to two-shot injection molding. If you have double shot injection molds purchase requirements, welcome to consult KRMOLD!

| 1 | Advantages of Two-shot Injection Molding |

| 2 | Experience and Skills of Two-shot Injection Molding Process |

1.Advantages of Two-shot Injection Molding

(1) production efficiency is improved.

Traditional injection molding process often needs to store raw materials in the middle. Repeated turnover operation not only consumes time, but also easily introduces impurities in the storage process, which affects the product quality. However, thetwo-color injection molding process cleverly avoids these disadvantages and can complete the manufacture of products in one injection process. It does not need complicated intermediate storage links, from raw material input to final product output in one go, which greatly shortens the production cycle.

Judging from the machine operation cycle, two-shot injection molding can realize the integrated molding of multiple materials, colors or functions in just one machine cycle. For example, when producing a tool with a soft grip, the traditional process may need to inject the tool body first, and then process the grip part, while the two-color injection molding can complete the combination of the tool body and the soft grip at one time in the same mold, without removing the main double shot injection molds and putting it into the second double shot injection molds for secondary processing, which greatly reduces the cost of double shot injection molds replacement.

At the same time, due to the simplification of production links, the labor time spent in manufacturing the final product has also been greatly reduced. For large-scale production and operation, this means that more items can be produced per unit time, and enterprises can respond to market demand faster and increase market share.

(2)Improve product quality

Compared with conventional painting process, two-color injection molding service has superior performance in color quality. The color presented by conventional painting process is not only easy to be erased in daily use, which affects the appearance of products, but also may cause problems such as uneven color and sagging during painting. However, by directly injecting and fusing materials of different colors, the two-shot injection molding has extremely high color fastness and greatly prolongs the color life.

The two-shot injection molding process not only eliminates the dependence on paint and avoids the environmental pollution caused by paint volatilization, but also makes the product look more exquisite and beautiful with high quality. For example, in the field of consumer electronics, the two-color injection molding process is adopted for the mobile phone shell, which can present gorgeous and lasting color effects and attract consumers' attention, thus effectively increasing product sales.

In addition, two-color injection molding can perfectly combine two different materials in one process without using adhesive. The use of adhesives often has risks such as aging and shedding, and the firm adhesion formed by two-color injection molding fundamentally eliminates such problems. Moreover, in terms of product design, its ergonomic design has obvious advantages. Through accurate double shot injection molds design and injection molding process control, misalignment between product parts can be minimized, assembly efficiency can be improved, and the overall quality and stability of products can be further improved.

(3)Expansion of diversified application fields

With its significantly enhanced performance, two-color injection moldingproducts can meet the needs of various complex use environments, which makes the two-shot injection molding service widely used in many industries.

In the medical industry, the requirements for product safety, hygiene and durability are extremely high. Medical equipment components manufactured by double injection molding process, such as syringes and medical device housings, not only have good biocompatibility, but also can achieve special functions such as antibacterial and anti-slip through the combination of different materials, ensuring the safety and efficiency of medical process.

In the aerospace field, the quality and reliability of parts are almost harsh. Two-color injection molding technology can produce high-strength and lightweight parts, meet the strict requirements of aerospace equipment for material properties, and provide a solid guarantee for the safe operation of aircraft.

In the automobile industry, the double injection molding technology has been widely used, from the dashboard and steering wheel in the interior to the bumper and lampshade in the exterior. It can combine materials with different hardness and colors, which not only meets the functional requirements of automobile parts, but also improves the aesthetics and comfort of automobile interiors.

The consumption field is the "main battlefield" of the double injection molding process. From daily electronic products and toys, to kitchen supplies and home decorations, the two-color injection molding process endows products with rich colors, unique appearance and excellent performance, which satisfies consumers' pursuit of personalized and high-quality products.

The military field has extremely high requirements for the durability and reliability of equipment. Military equipment parts manufactured by two-color injection molding process can maintain good performance in harsh environment and provide strong support for the smooth development of military operations.

(4)High degree of freedom of choice

Two-shot injection molding provides a high degree of freedom for product design. In the design of products in process, designers can give full play to their creativity and create exquisite, unique and personalized products through the combination of different colors and materials to meet the increasingly diverse aesthetic needs of consumers.

According to the use characteristics of the product, the manufacturer can freely choose the core and skin materials. For example, when producing a piece of sports equipment, you can choose high-strength materials as the core to ensure the durability of the product, and at the same time choose soft and non-slip materials as the skin to improve the user's grip comfort. This way of freely selecting materials does not need complicated assembly procedures, which reduces the seams of products, not only improves the production efficiency, but also solves the mass production problem of products with special structures. For some products with special functional requirements, such as waterproof, dustproof and shockproof, the two-shot injection molding process can easily realize these functions through clever material combination and double shot injection molds design, which provides a broad space for product innovation.

2.Experience and Skills of Two-shot Injection Molding Process

When using two-color injection molding, manufacturers need to pay attention to some skills and points to ensure product quality and production efficiency. The following are some issues worthy of attention:

(1) Choose the right material: Two-shot injection molding requires the use of two different materials, which need to be carefully selected to ensure that they can be perfectly integrated and compatible.

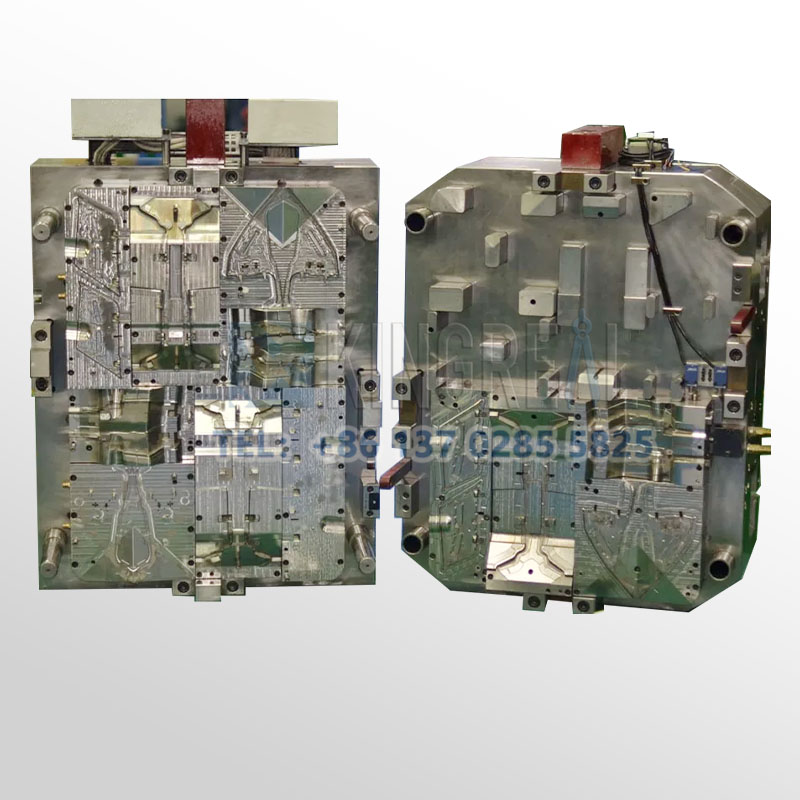

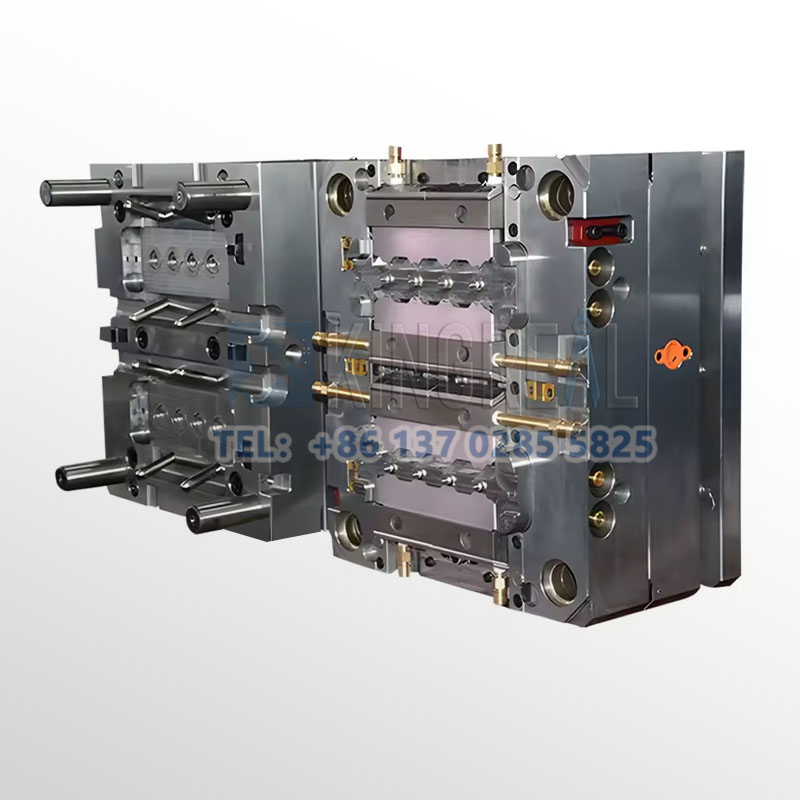

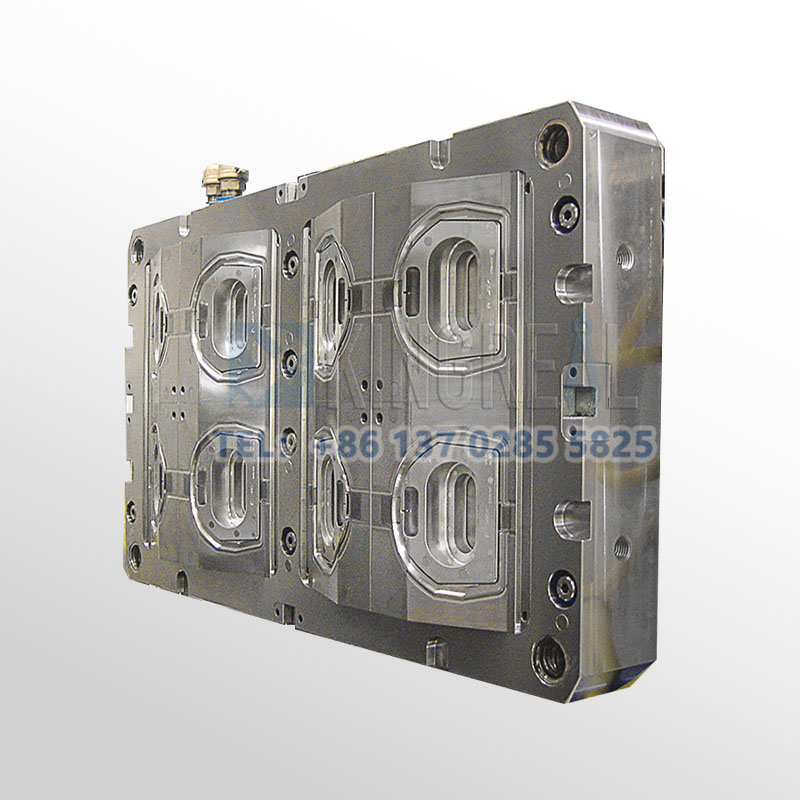

(2) Mold design: The two-color injection molding process needs to use a complex double shot injection molds to accommodate two kinds of materials, so the double shot injection molds design and manufacturing requirements are very high.

(3) Control injection parameters: In the two-shot injection molding process, injection parameters, such as temperature, pressure and speed, need to be carefully controlled to ensure that the two materials can be injected into the double shot injection molds perfectly and achieve high quality manufacturing.