KINGREAL UNIVERSAL IND., LTD

Phone

+86-13702855825| 1 | Introduction of Gas-assisted Injection Molding |

| 2 | Basic Principle of Gas-assist Injection Molding |

| 3 | Characteristics of Gas-assist Injection Molding Technology |

| 4 | Advantages of Gas-assist Injection Molding Technology |

| 5 | Factors to Consider When Choosing Gas-assisted Injection Molding |

1.Introduction of Gas-assisted Injection Molding

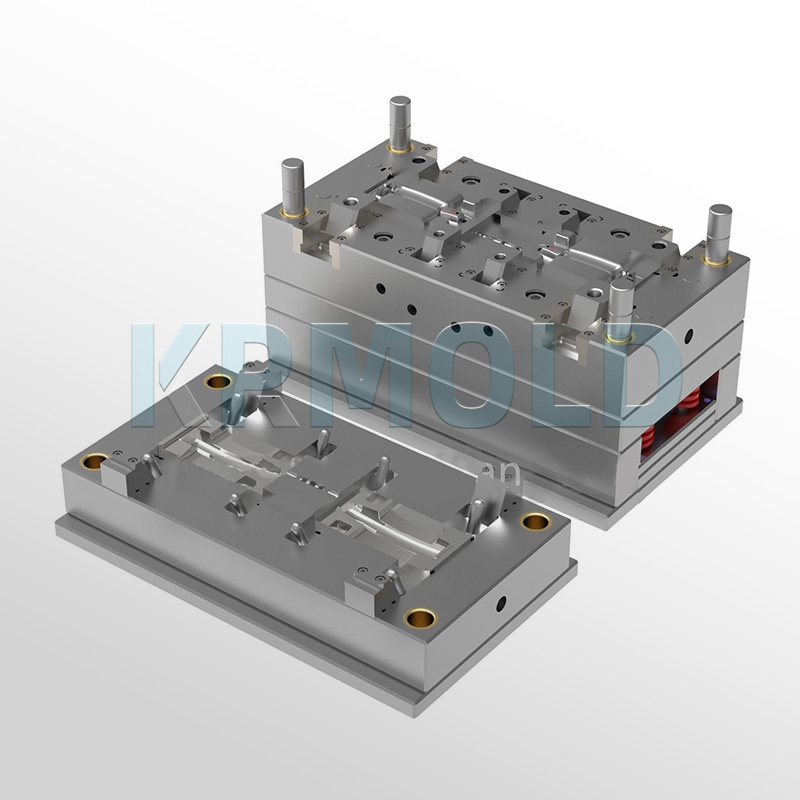

| Gas-assisted injection molding is a common process in plastic injection molding. It requires a certain amount of molten plastic to be injected into the mold, and then an inert gas (usually nitrogen) is injected into the core of the part. The gas forms a hollow channel inside the part, which helps to reduce material usage, increase part strength and improve surface finish. If you want to produce large plastic parts, such as car bumpers and furniture parts, gas-assist injection molding is a wise choice. In this article, KRMOLD will give you a detailed introduction to gas-assisted injection molding. If you need more information or materials, please consult KRMOLD! KRMOLD is committed to providing customers with high-quality gas-assisted injection molds. |  |

2. Basic Principle of Gas-assist Injection Molding

| Gas-assisted injection molding is divided into four stages: melt short shot, gas injection, gas pressure holding, gas exhaust and part ejection. (1) Melt short shot: Plastic melt is injected into the cavity, and the melt occupies 60%'95% of the cavity. The actual pre-injection amount varies from product to product and is determined by CAE analysis and process tests. (2) Gas injection: High-pressure inert gas (usually nitrogen) is injected into the core of the melt. The melt flow front continues to flow forward under the impetus of the high-pressure gas, and eventually fills the entire cavity. The high-pressure gas forms a hollow section inside the part. (3) Gas pressure holding: The gas maintains a certain pressure, so that the part gradually cools under the uniform pressure holding effect. In this stage, the gas applies pressure from the inside to the outside to ensure that the outer surface of the product is close to the mold wall; and through the secondary penetration of the gas, the volume shrinkage caused by the cooling and solidification of the melt is supplemented from the inside. Gas pressure holding generally includes two stages: high-pressure pressure holding and low-pressure pressure holding. (4) Gas discharge and part ejection: After pressure holding and cooling, the part has sufficiently high rigidity and strength, and then the gas is discharged; a part of the gas can be reused by using a recovery device, and the rest is discharged into the atmosphere. The part is further cooled and then ejected. |

3.Characteristics of Gas-assist Injection Molding Technology

| Injection molded parts with alternating thick and thin walls are difficult to process with traditional injection molding processes because of their large residual stress, easy warping and deformation, and shrinkage marks on the surface. However, due to the action of chemical foaming agents, bubbles are formed inside the plastic parts in the structural foaming technology, and cavitation is easily formed on the surface of the parts. The decorative parts made by this process need to be sprayed. Gas-assisted injection molding technology is developed on the basis of traditional injection molding and structural foaming molding. It has the advantages of both: using high-pressure nitrogen, the inside of the thick wall of the injection molded part can be hollowed out to form a hollow section inside the plastic part; through gas pressure maintenance, it not only promotes melt filling and eliminates shrinkage marks on the surface of the part, but also avoids the disadvantage of spraying the surface of the structural foamed part, which can significantly reduce costs and ensure good molding quality. |  |

4.Advantages of Gas-assist Injection Molding Technology

⚪ Reduce the residual stress of the product and reduce warping deformation; ⚪ Eliminate the problem of surface shrinkage marks of the product; ⚪ Reduce the clamping force requirements of the gas-assisted injection molding machine, which can be reduced by 40%~60%; ⚪ Increase the life of the gas-assist injection molding machine; ⚪ Introduce plastic raw materials without changing the product size, which can reach 20%~40%; ⚪ Shorten the molding cycle, which can reach 30%; ⚪ Reduce the pressure in the mold and reduce the wear on the mold; ⚪ Simplify product design; ⚪ It becomes possible to use aluminum molds. |  |

5.Factors to Consider When Choosing Gas-assisted Injection Molding

When choosing the gas-assist injection molding technology, we need to evaluate several key factors that may affect the quality of the final product, cost, production efficiency, etc.

1

Material properties

The mechanical, thermal and chemical requirements of the final product determine the manufacturer's material selection.

If high strength and heat resistance are required, metals or high-performance thermoplastics can usually be selected.

It is important to understand the melting point, viscosity and shrinkage characteristics of the material.

2

Part design complexity

Complex designs may require specialized skills. For example, multiple injection molding or gas-assisted injection molding, which require specialized techniques.

To ensure that the part can be filled and injected correctly, manufacturers must consider factors such as mold tilt, wall thickness uniformity, gate and vent location.

3

Production volume

High-volume production is suitable for processes such as traditional plastic injection molding, which can be achieved through automated production lines with high efficiency and low unit cost.

If it is a small batch or prototype production, more flexible methods such as 3D printing or low-pressure injection molding will be better.