KINGREAL UNIVERSAL IND., LTD

Phone

+86-13702855825| 1 | How Are Plastic Chairs Manufactured? |

| 2 | Customized Plastic Injection Chair Mould Design Solutions |

| 3 | What is Difference Between Single-cavity and Multi-cavity Plastic Chair Injection Mold? |

| 4 | How Long is Lifespan of Plastic Chair Injection Mold? |

There is a significant market demand for plastic chair injection molds because they enable the mass production of highly consistent plastic chairs.

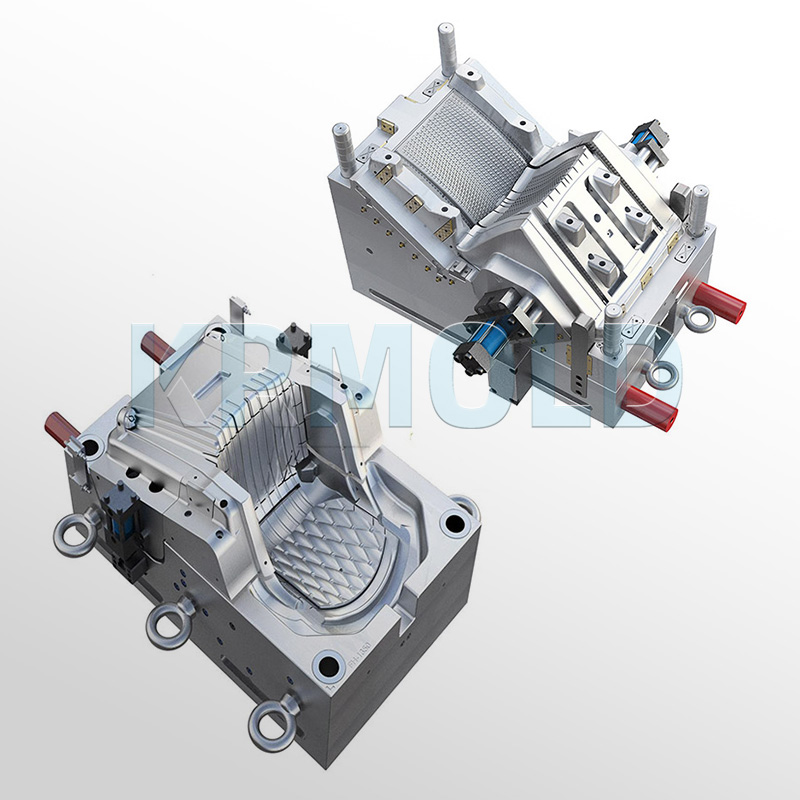

KRMOLD plastic injection chair mould can produce chairs of various sizes, shapes, and appearances to meet different customer requirements for various applications, including children's chairs, adult chairs, indoor chairs, outdoor chairs, armchairs, armless chairs, classic styles, and personalized European-style chairs. This article from KRMOLD will provide a detailed introduction to plastic chair injection molds, helping you gain a deeper understanding of plastic injection chair mould.

1.How Are Plastic Chairs Manufactured?

The production process of plastic chairs typically includes the following key steps:

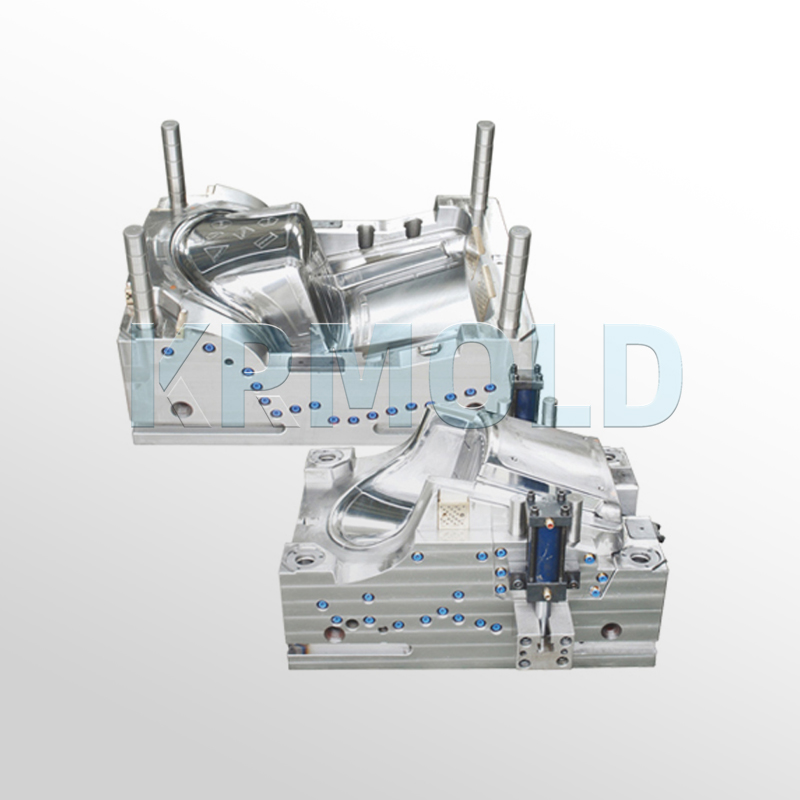

-Plastic chair injection mold closure and pressure setting: The plastic injection chair mould must first be closed and the proper pressure set during injection molding. This is absolutely necessary for guaranteeing the plastic inside the plastic chair injection mold runs smoothly and shapes itself.

-Injection: An injection molding machine shoots molten plastic into the plastic injection chair mold. The adjustment of injection pressure and speed is very important at this point. Too fast or too slow injection speeds might compromise the quality of the ultimate product.

-Maintaining pressure and temperature: Correct pressure and temperature must be kept following injection to enable the plastic to flow completely within the plastic chair injection mold and assume the shape wanted. Usually this procedure takes tens of seconds to few seconds.

-Cooling and demolding: The temperature inside the plastic injection chair mould slowly lowers once the plastic is totally molded; the plastic chair cools and hardens. Opening the plastic chair injection mold allows the finished chair to be removed.

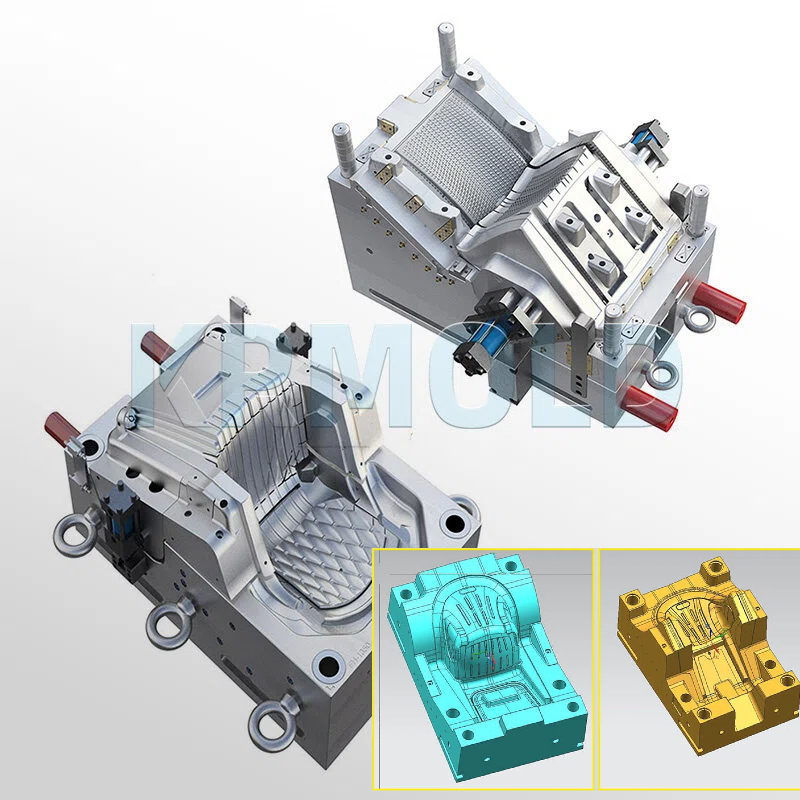

2.Customized Plastic Injection Chair Mould Design Solutions

KRMOLD emphasizes customized plastic chair injection mold design in the manufacture of plastic injection chair mould to meet the needs of different customers. Plastic chair injection mold design involves not only the shape and size of the chair but also aspects such as color and function.

For example, KRMOLD engineers focus on the following key factors during the manufacturing process:

-Cycle Time: Plastic injection chair mould design needs to be optimized to shorten the production cycle and improve production efficiency.

-Parting Line: A reasonable parting line design can effectively improve the appearance quality of the product and reduce subsequent finishing work.

-Wall Thickness: Appropriate wall thickness design ensures the strength and aesthetics of the chair while reducing material waste.

-Ventilation Design: A good venting design can prevent air bubbles from forming during injection molding, thereby improving product quality.

3.What is Difference Between Single-cavity and Multi-cavity Plastic Chair Injection Mold?

When choosing a plastic chair injection mold, the choice between single-cavity and multi-cavity plastic injection chair mould significantly impacts production capacity and cost-effectiveness.

●Single-cavity plastic chair injection mold

Single-cavity plastic injection chair mould can only produce one chair at a time. Their main characteristics include:

-High single-piece precision: Single-cavity plastic chair injection molds provide better product accuracy appropriate for products needing tight dimensional specifications since only one chair is made at a time.

-Easy maintenance and adjustment: Single-cavity plastic injection chair molds feature a relatively straightforward design, therefore they are perfect for prototyping or small-batch manufacture since maintenance and modification are simpler.

●Multi-cavity plastic chair injection mold

Multi-cavity plastic injection chair mould can produce multiple chairs at once. Their main advantages are:

-Increased output: Multi-cavity plastic chair injection molds can produce multiple chairs simultaneously, significantly improving production efficiency.

-Shorter Production Cycles: Increased production quantities significantly shorten the production cycle, making it suitable for large-scale production needs.

-Reduced Unit Costs: Multi-cavity plastic injection chair mould can effectively reduce the cost per unit in large-scale production.

The choice between single-cavity and multi-cavity plastic chair injection molds depends on production goals and strategies. Single-cavity plastic injection chair mould provide more flexibility and control if you are producing in small batches or creating samples. Multi-cavity plastic chair injection molds enable you to attain greater production without compromising quality when fast scaling up of production is needed.

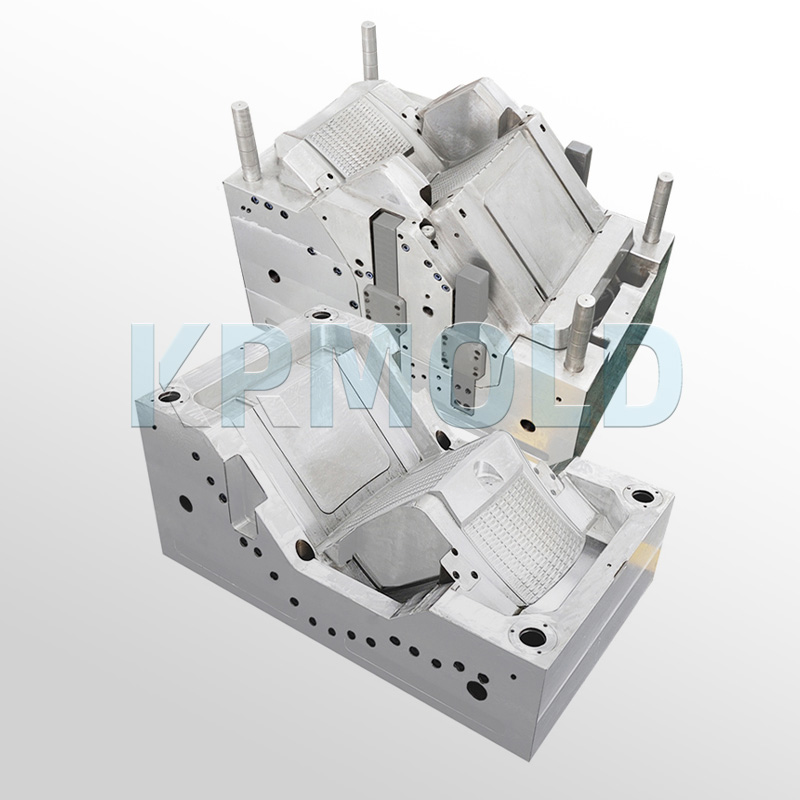

4.How Long is Lifespan of Plastic Chair Injection Mold?

When spending on plastic injection chair mould, durability is a vital factor. High-quality hardened steel used in KRMOLD plastic chair injection molds can survive hundreds of thousands or even millions of injection cycles without major performance loss.

●Factors affecting plastic injection chair mould lifespan

-Material Selection: The mold material directly determines its durability. High-quality materials effectively resist wear and extend service life.

-Surface Treatment: Good surface treatment improves mold efficiency, prevents material adhesion, and lowers friction on the plastic chair injection mold surface.

-Maintenance Procedures: Regular cleaning and inspection are essential for ensuring the long-term efficient operation of the plastic injection chair mould. Neglecting maintenance can lead to decreased mold performance, thus affecting product quality.

Moreover, the sort of plastic used and the complexity of the chair design affect on the life span of the plastic chair injection mold. Particularly in places with rich textures or thin walls, highly abrasive or fiber-filled substances speed mold deterioration. Chairs with smooth shapes and basic designs, however, strain the plastic injection chair mould less and often last a longer without significant maintenance or polishing.