KINGREAL UNIVERSAL IND., LTD

Phone

+86-13702855825| 1 | Home Appliance Plastic Injection Mold Material Selection |

| 2 | Key Points in Home Appliance Injection Mold Design and Manufacturing |

| 3 | Precise Control of Injection Molding Process Parameters |

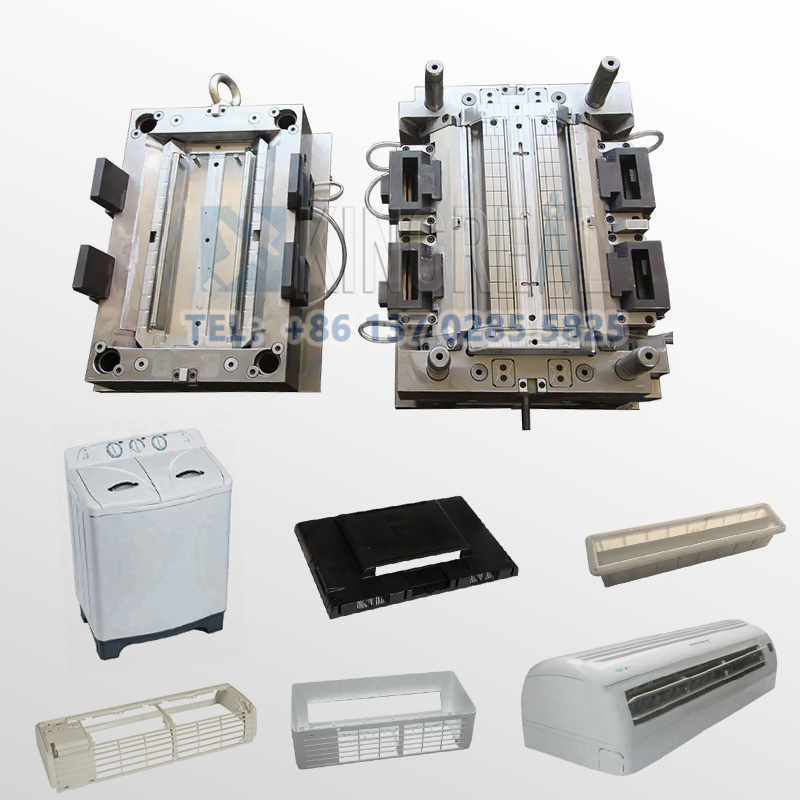

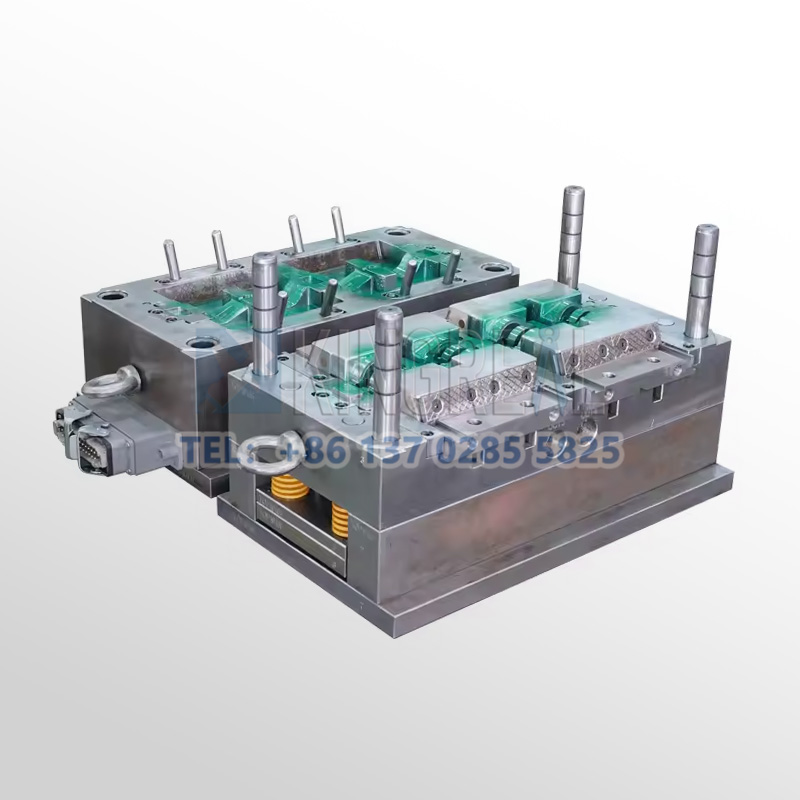

Home appliance injection molds allow for the manufacture of accurate components including microwave oven components, refrigerator doors, and washing machine panels.Therefore, the quality of these home appliance plastic injection molds directly affects product quality, price, and lifetime.

With 20 years of expertise in the field, KRMOLD, a professional home appliance injection mold producer, offers specialized mold manufacturing solutions to fulfill unique needs for high-temperature resistance, corrosion resistance, and electromagnetic shielding.

Providing top industry knowledge, this piece will examine the design, material selection, and process improvement of home appliance plastic injection molds.

1. Home Appliance Plastic Injection Mold Material Selection

(1) Appearance and Texture Requirements

Ordinary items, home appliances' texture and design have a direct bearing on customer purchasing decisions.Consequently, the material for home appliance plastic injection molding should fulfill these look demands.High-end home appliances, for instance, like smart TV bezels and air conditioner panels, usually incorporate high-gloss, high-finish materials like ABS and PC alloy .Besides great home appliance injection molding and processing qualities, this alloy material can provide a mirror-like finish via home appliance plastic injection molding, with a glossiness greater than 90 (gloss unit), therefore improving the aesthetics of home appliances.

Moreover, to produce various textures—like simulated metal or matte finishes—unique pigments or additives can be introduced to the material; or specialized injection molding techniques such textured injection molding and two-color injection molding can be used.Two-color injection molding, for instance in the home appliance injection molding of refrigerator door handles, combines soft rubber with hard plastic to guarantee a pleasant grip while also producing a distinctive design, therefore fulfilling consumers' dual demands for aesthetics and functionality in appliances.

(2) Durability and Functionality Requirements

Home appliances are subject to the rigors of various environmental factors and operating conditions over long periods of use. Therefore, home appliance plastic injection molding materials need to be really durable and practical.Regarding endurance, the substance should display great abrasive, aging, and weather resistance.For instance, ASA is sometimes used in the external shell of an outdoor air conditioner as it is highly weather-resistant. ASA keeps color stability and mechanical properties under challenging circumstances including protracted UV exposure, wind, and rain, and its weather resistance is several times greater than that of conventional ABS.

Regarding wear resistance, for household appliance components that frequently come into contact with the human body or other objects, such as washing machine knobs and remote control buttons, highly wear-resistant materials such POM are recommended.

POM, with its low coefficient of friction and high hardness, offers significantly higher wear resistance than ordinary plastics, effectively preventing wear and scratches from frequent use and extending the lifespan of household appliances. From a functional perspective, for injection-molded parts in household appliances requiring specialized functions, such as microwave oven doors with electromagnetic shielding, plastic materials containing conductive fillers can be used.

By uniformly dispersing the conductive fillers throughout the plastic matrix through the injection molding process, the molded parts possess excellent electromagnetic shielding properties, meeting the requirements for preventing electromagnetic leakage during microwave operation and protecting user health and safety.

2. Key Points in Home Appliance Injection Mold Design and Manufacturing

(1) High-Precision and Complex Structure Design for home appliance plastic injection molds

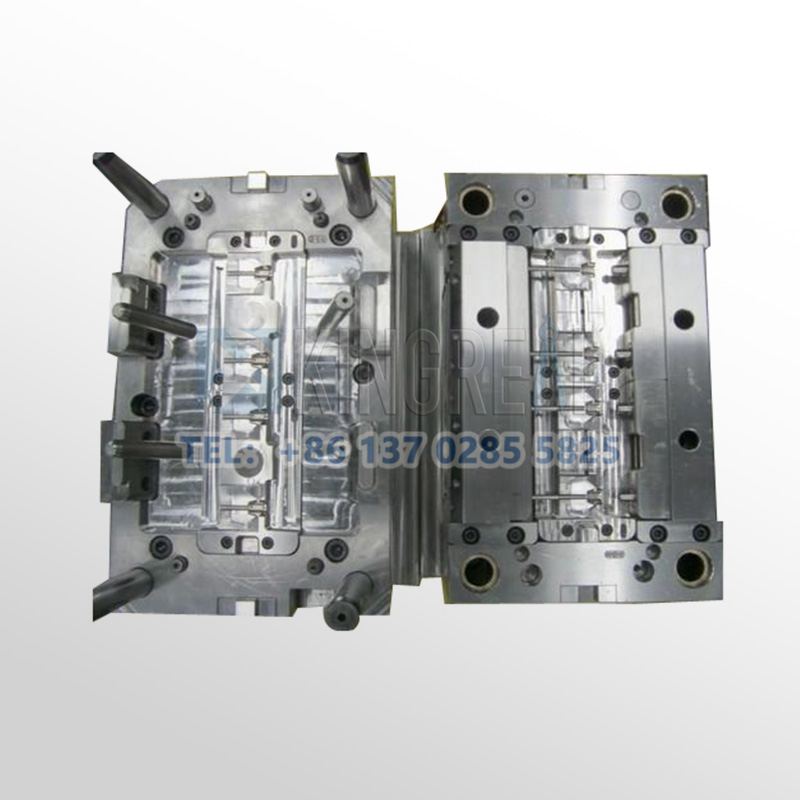

High dimensional accuracy expectations and sophisticated structures often characterize precision injection molded components for domestic appliances.For instance, little optical structures like dots and prisms cover the light guide plate (LGP) in the backlight module of an LCD TV.The dimensional accuracy and dispersion uniformity of these buildings have a direct bearing on the backlight module's light effect and evenness.

High-precision machining tools and methods including ultra-large CNC machining centers, electrical discharge machining (EDM), and wire-cut machining are needed during home appliance injection mold design and manufacture to guarantee micron-level or even submicron-level dimensional accuracy for the home appliance plastic injection mold core and cavity.The dot structure must be manufactured for the LGP mold with an accuracy of within ±0.005mm and the prism angle tolerance must be kept within ±0.1°.

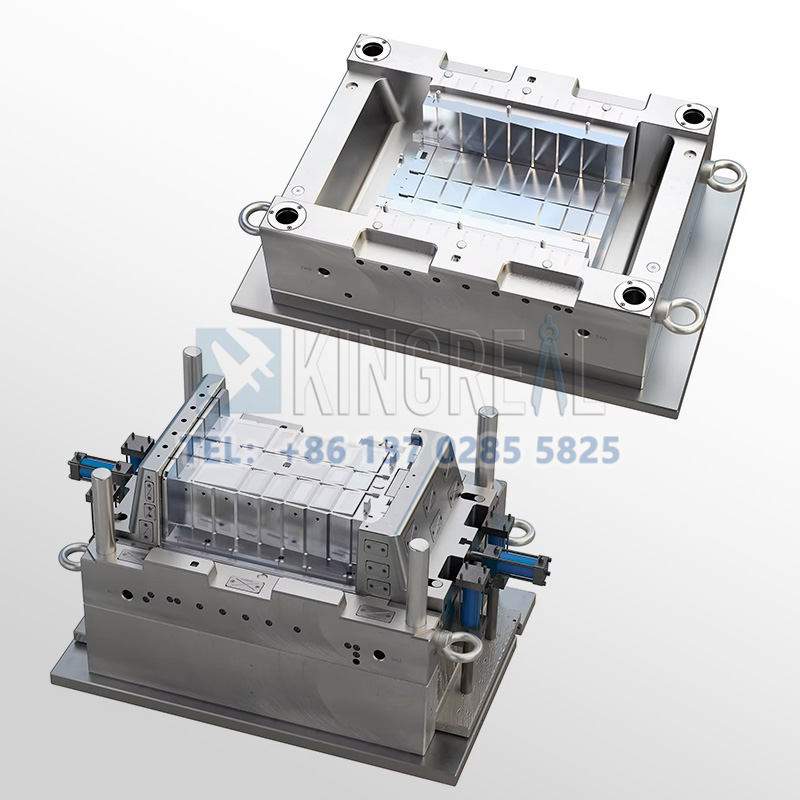

Furthermore, to achieve the home appliance injection molding of complex structures, the design of the home appliance plastic injection mold's demolding mechanism is crucial.

For injection molded parts with undercuts and side holes, such as blade molds for air conditioner vents, specialized demolding methods such as slider demolding, tilted ejection, or rotary demolding are required. The demolding process must be smooth and seamless, without damaging the part's structure or precision.

(2) Hot Runner System Applications for home appliance injection molds

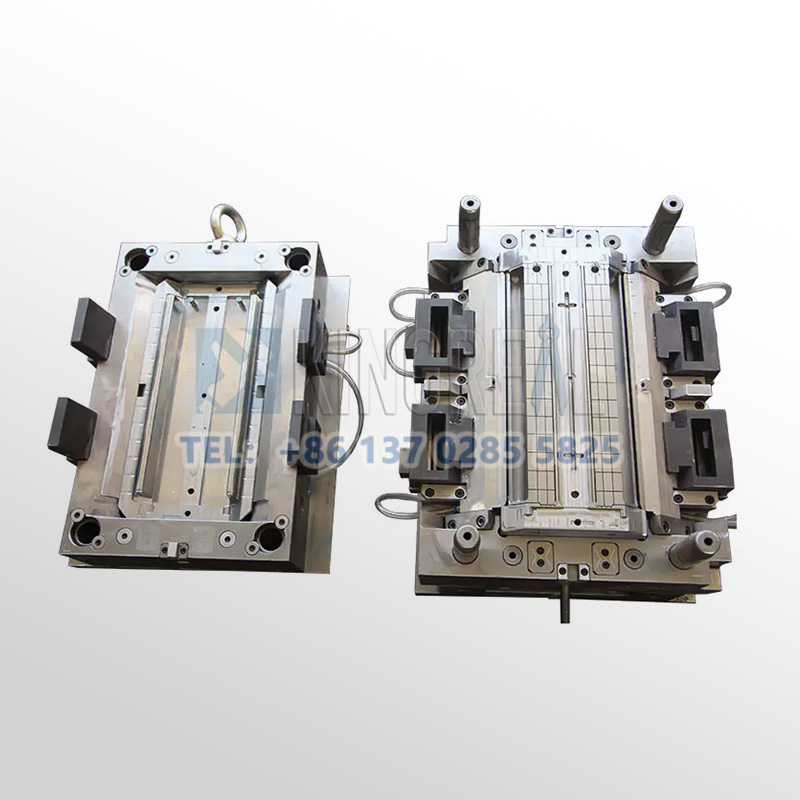

For home appliances, exact home appliance injection molding now uses hot runner systems more and more.They guarantee great temperature homogeneity and mobility inside the mold cavity, therefore lowering plastic trash and raising injection efficiency and product quality.

For big home appliance components like refrigerator cabinets and washing machine drums, hot runner systems can successfully prevent injection defects such sink marks and warpage brought on by too much cold runner congealment.Based on the shape, size, and material characteristics of the component, the design of the hot runner system must be modified.

Designing the hot runner's runner diameter, length, and heating power, for instance, calls for consideration of the rheological characteristics of the plastic melt to guarantee steady and consistent flow inside the runner, devoid of stagnation or breakdown.

Moreover, the hot runner system's temperature control precision is essential; usually, ±1°C temperature control is needed to guarantee a steady melt temperature and raise the molded components quality.Additionally needing great care is the sealing and maintenance of the hot runner system.Regular checks of parts including the hot runner seals and heating components are absolutely vital to fast identify and fix any leaks, short circuits, and other problems so guaranteeing correct operation of the hot runner system.

3. Precise Control of Injection Molding Process Parameters

(1) Temperature Parameters

Injection temperature has a significant impact on the molding quality of precision molded parts for home appliances. Among several home appliance plastic injection molding formulations are varying melting point ranges and thermal stability needs.For PC/ABS alloy, for instance, the barrel temperature usually falls between 240 and 280°C; the nozzle temperature is somewhat lower, around 230 to 260°C.Mold temperature management has to be changed according on the form and size of the molded piece.

Usually, for thin-walled items, the home appliance injection mold temperature can be regulated between 60 and 80 degrees Celsius to hasten cooling and boost manufacturing efficiency.For thick-walled pieces, the home appliance plastic injection molding temperature can be raised to 80 to 100°C.This lowers shrinking cavities and internal bubble production by letting the melt flow and preserve pressure inside the home appliance injection mold cavity.

To guarantee that the plastic melt keeps great fluidity and stability throughout the whole procedure, temperature settings during the home appliance plastic injection molding process must be changed in real time depending on variables including the performance of the injection molding machine and the mold's heat exchange efficiency, therefore producing high-quality precision molded home appliance parts.

(2) Pressure and Speed Parameters

The melt filling procedure inside the mold cavity is directly influenced by injection speed and pressure.Injection pressure has to be great enough to guarantee the melt fills the mold cavity smoothly and surmounts flow resistance.Too much stress, though, can cause flash and too much internal pressure in the molded part.Injection pressure for exact home appliance injection molding usually spans 60 to 100 MPa; the particular level is determined by part complexity, material viscosity, and wall thickness among other elements.

For instance, for home appliance plastic injection molding with complicated constructions and uneven wall thickness—that of vacuum cleaner housings—segmented injection pressure control depending on the wall thickness and structural characteristics of various components is needed.To guarantee even melt filling of the mold cavity, pressure is properly lowered in thin-walled areas while pressure is raised in thicker areas and regions with higher flow resistance.

Controlling injection speed is also critical. Excessively fast injection speeds can cause melt turbulence in the mold cavity, entraining air and forming bubbles, while too slow injection speeds can cause premature cooling of the melt, resulting in underfill. In the home appliance injection molding process, multi-stage injection speed control can be employed. Initially, a faster speed is used to quickly fill the majority of the mold cavity.

Then the speed is slowly decreased to maintain pressure and feed the mold cavity so guaranteeing dimensional correctness and internal quality of the molded component.For instance, when filling the first 50% of the cavity volume, the injection speed can be set to 4060mm/s, then slowly dropped to 2030mm/s for pressure holding.

This can effectively reduce the occurrence of defects such as bubbles and weld marks, improve the quality and performance of precision injection molded parts for home appliances, and meet the home appliance industry's requirements for high quality and high precision products.