KINGREAL UNIVERSAL IND., LTD

Phone

+86-13702855825"Motor cover molds play a vital role in modern manufacturing. They not only affect the quality of products, but also directly relate to production efficiency and cost control. However, the service life of plastic engine cover toolings is not a fixed value. It is affected by many factors. Today, KINGREAL MOLD will explore these factors in depth and put forward corresponding maintenance and management suggestions to extend the service life of the glass fiber reinforced plastic engine mold and ensure the efficiency and economy of production."

1/Factors affecting the life of motor cover molds

Mold design

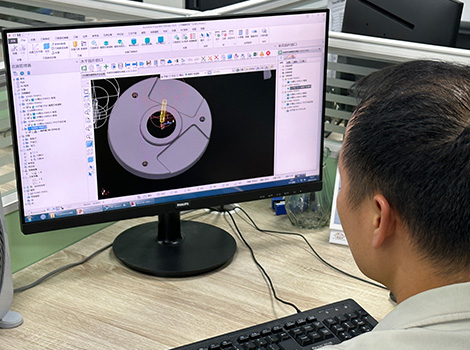

The design of the plastic engine cover tooling also has an important impact on its service life. An excellent mold design can not only ensure the quality of the product, but also reduce glass fiber reinforced plastic engine mold wear and extend its service life. When designing, factors such as the motor cover mold's cooling system, exhaust system and processing accuracy need to be considered, which directly affect the overall performance and durability of the plastic engine cover tooling.

High-quality steel has excellent wear resistance and corrosion resistance, and can withstand long-term high-pressure motor cover molding processes, thereby significantly extending the plastic engine cover tooling. Motor cover mold material is the primary factor that determines its service life. High-quality steel has excellent durability and service life. On the contrary, if low-quality materials are used to make glass fiber reinforced plastic engine molds, the plastic engine cover toolings are prone to cracks, deformation and other problems during use, which greatly shortens the motor cover mold life.

Processing accuracy

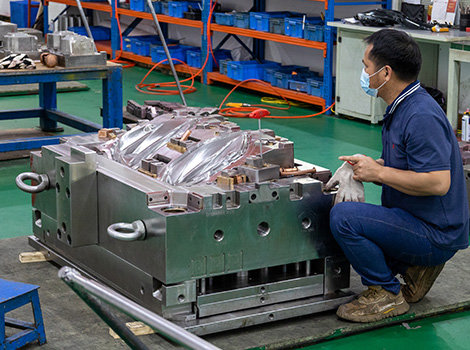

The processing accuracy of the plastic engine cover tooling is also one of the key factors affecting its service life. High-precision mold processing can ensure the tightness of each part of the glass fiber reinforced plastic engine mold, reduce friction and wear during the motor cover molding process, and effectively extend the service life of the plastic engine cover tooling. Therefore, the use of high-precision processing equipment and technology is an important means to improve the service life of the plastic engine cover tooling.

Use and maintenance

The use and maintenance of the glass fiber reinforced plastic engine mold also have a direct impact on its life. Standardized operation can reduce abnormal wear of the plastic engine cover tooling, and regular maintenance and care can timely detect and repair mold damage and prevent small problems from turning into big problems, which is crucial to extending the service life of the plastic engine cover tooling.

Production environment

The temperature, humidity and cleanliness of the production environment will also affect the service life of the glass fiber reinforced plastic engine mold. Harsh environmental conditions will accelerate the wear and corrosion of the plastic engine cover tooling, so maintaining a good production environment is of great significance to protecting the motor cover mold and extending its service life.

2/Methods to extend motor cover molds

1. Optimize mold design

Reasonably design the mold structure: ensure that the glass fiber reinforced plastic engine mold can withstand the pressure and temperature changes during the motor cover molding process, while reducing unnecessary wear and damage.

Optimize the cooling system: design a reasonable cooling channel to ensure uniform mold temperature and avoid deformation and damage caused by local overheating.

Choose the right parting surface: The parting surface should be chosen to facilitate the opening and closing of the plastic engine cover tooling and reduce the wear of the motor cover mold.

2. Choose high-quality mold material

Choose mold steel with good wear resistance: such as P20, 2738, H13 and other mold steels. These materials have high hardness and wear resistance and can extend the service life of the plastic engine cover tooling.

Ensure the quality of mold materials: Avoid using mold materials with defects such as inclusions and uneven distribution of carbides, which will cause cracks and failure of the motor cover mold during use.

3. Reasonably set injection molding process parameters

Control glass fiber reinforced plastic engine molding pressure and speed: Excessive motor cover molding pressure and speed will cause excessive wear of the plastic engine cover tooling, and should be reasonably adjusted according to the requirements of mold materials and glass fiber reinforced plastic engine molding products.

Optimize injection temperature: The injection temperature should be controlled within an appropriate range to avoid damage to the plastic engine cover tooling caused by excessively high or low temperatures.

Adjust mold temperature: Limit the mold temperature to the minimum requirement for acceptable part appearance to reduce damage to the motor cover mold caused by thermal stress.

4. Strengthen the maintenance of motor cover molds

Clean the mold regularly: After each use of the plastic engine cover tooling, it should be cleaned immediately to avoid plastic residue in the glass fiber reinforced plastic engine mold, which will cause corrosion and damage to the plastic engine cover tooling.

Keep the mold dry: After cleaning, the motor cover mold should be thoroughly dried to avoid moisture retention inside the motor cover mold causing rust and corrosion.

Lubricate the mold regularly: Use a special lubricant to lubricate the sliding parts of the plastic engine cover tooling to maintain the flexibility and normal operation of the glass fiber reinforced plastic engine mold.

Check the wear of the mold regularly: Perform a comprehensive inspection of the glass fiber reinforced plastic engine mold at regular intervals, especially the sliding parts and cores of the plastic engine cover tooling. If there is wear or damage, it should be repaired or replaced in time.

5. Correctly install and debug the motor cover mold

Ensure the correct installation of the mold: When installing the plastic engine cover tooling, ensure that all parts of the mold are correctly installed and adjusted to avoid damage to the glass fiber reinforced plastic engine mold due to incorrect operation.

Debug the mold: Before formal production, the motor cover mold should be debugged to ensure smooth opening and closing of the plastic engine cover tooling, and check whether all parts of the glass fiber reinforced plastic engine mold are tight and reliable.

6. Other precautions

Avoid overcooling or heating the mold: Overcooling or heating will cause deformation and damage to the plastic engine cover tooling, and the temperature of the cooling and heating system should be properly controlled. Avoid applying excessive impact force to the mold: to avoid cracking and damage to the glass fiber reinforced plastic engine mold. Store the mold properly: store the plastic engine cover tooling in a dry and ventilated place to avoid deformation and damage caused by moisture and high temperature environment.