KINGREAL UNIVERSAL IND., LTD

Phone

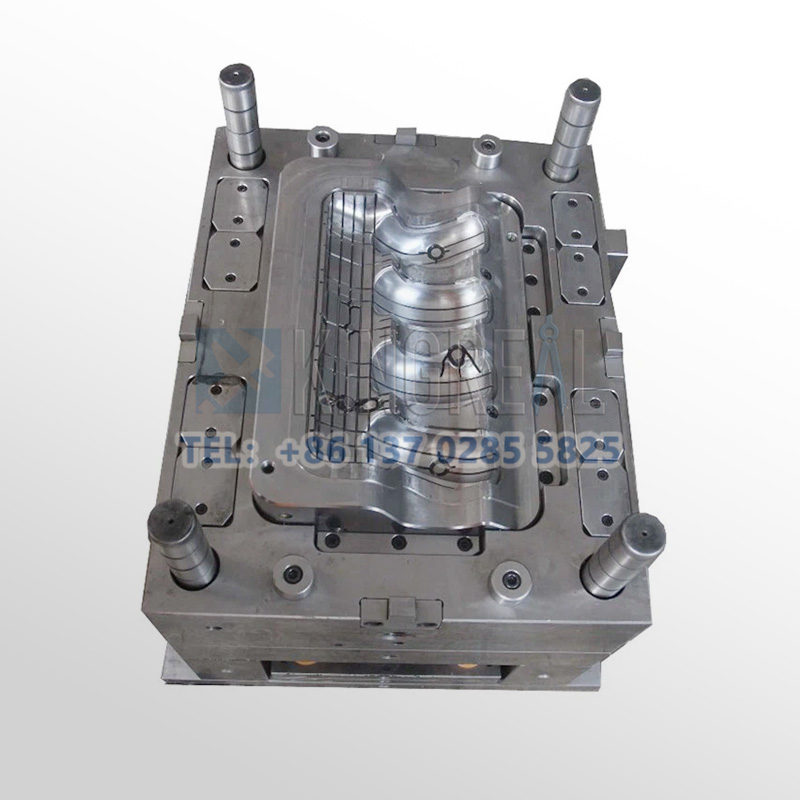

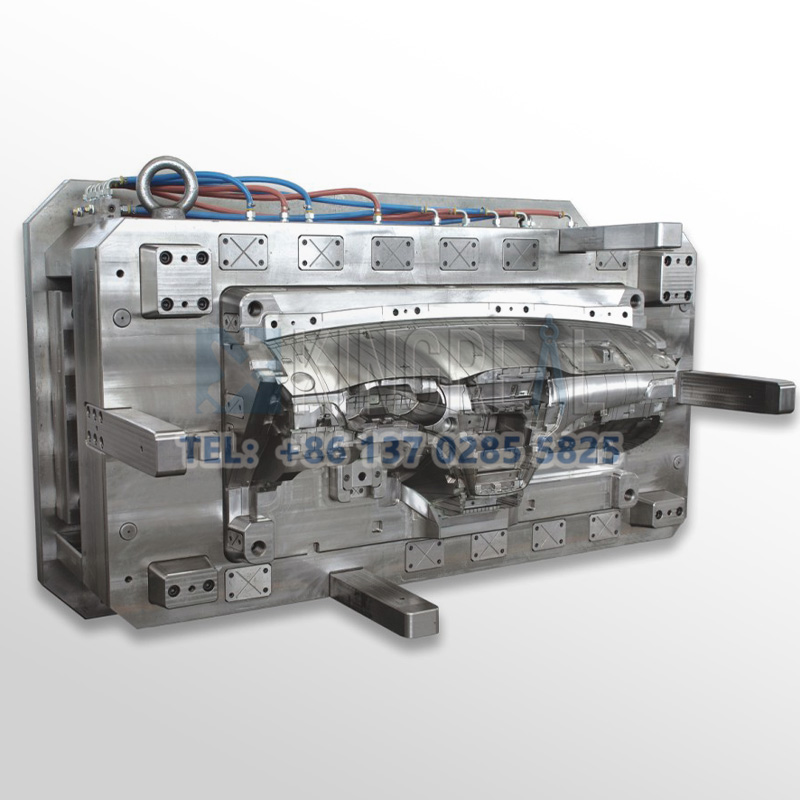

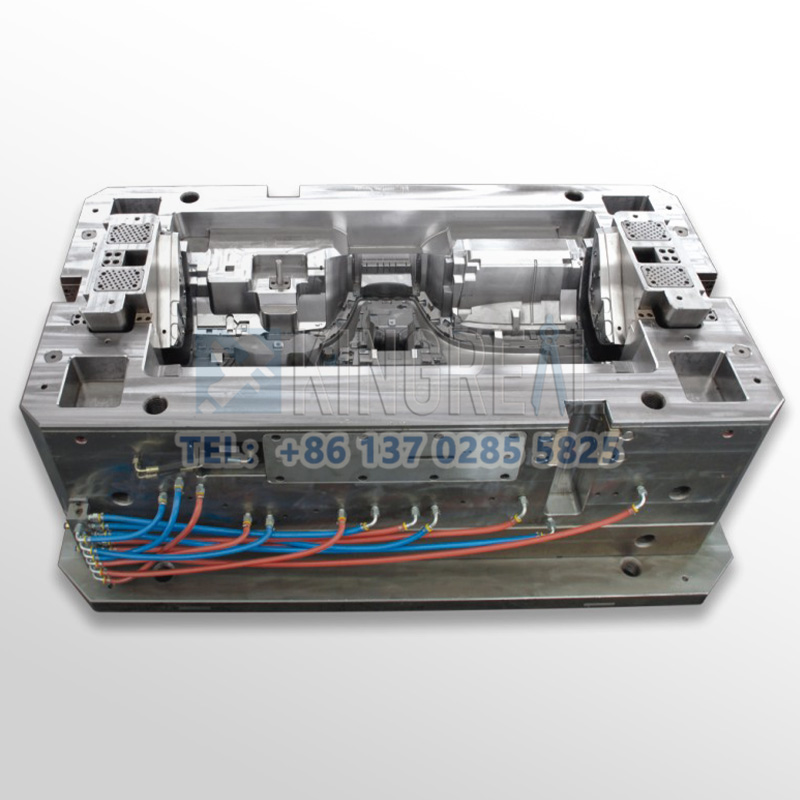

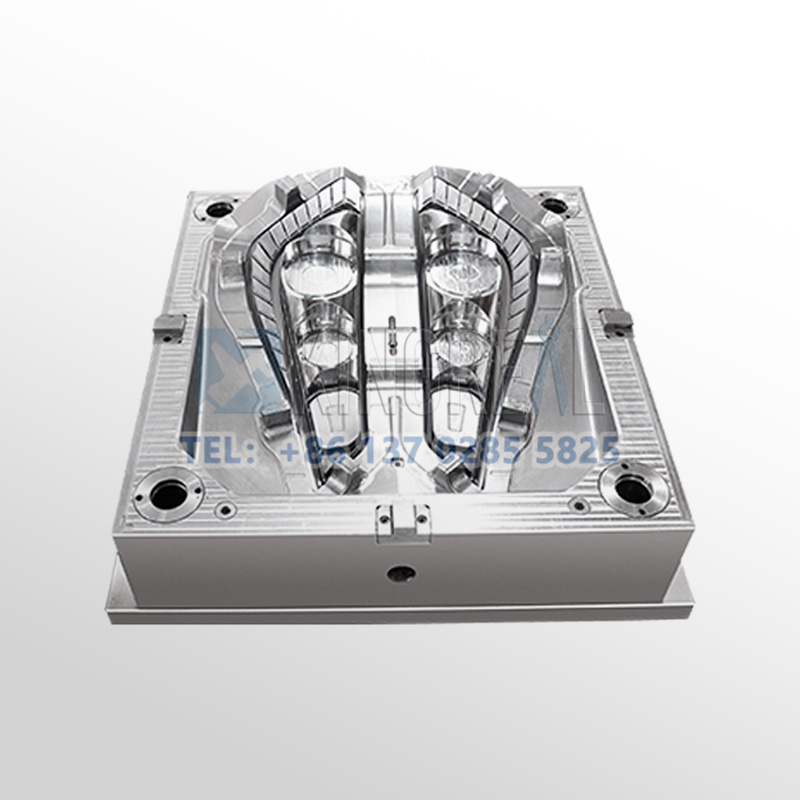

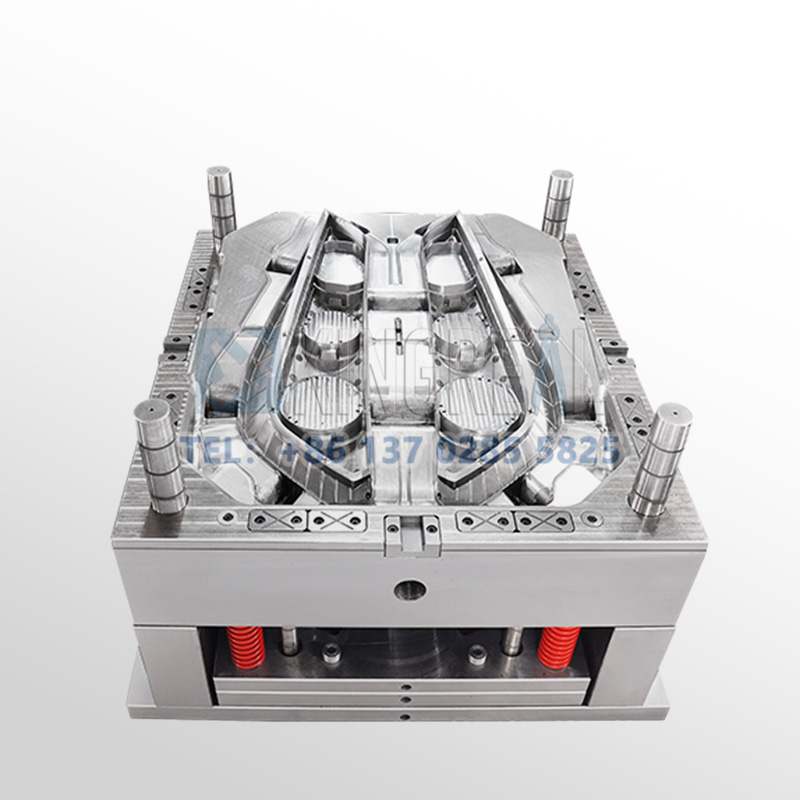

+86-13702855825"In the design of car head light plastic injection mold, cooling system plays a vital role, and the rationality of its design is directly related to product quality, production efficiency and production cost. An efficient cooling system can ensure uniform cooling of injection molded parts during the automotive lamp lens car light moulding process, reduce internal stress, deformation and dimensional deviation, and thus improve product precision and performance."

1/Injection mold cooling structure analysis

Part cooling time usually refers to the period from when the plastic melt fills the cavity to when the car head light plastic injection mold can be opened to remove the part. The automotive lamp lens car light moulding opening and removal of the part is based on the fact that the part has been fully solidified and has a certain rigidity and strength. Usually, when designing the cooling system, the longest cooling time required for the plastic part to reach the demolding temperature should be selected. The heat exchange between the plastic and the coolant is completed through heat conduction in the car head light plastic injection mold. The high-temperature melt enters the cold mold cavity, causing the temperature of the automotive lamp lens car light moulding cavity wall to rise. Most of its heat is transferred to the cooling water flow and taken away. The rest is transferred to the surrounding environment by the car head light plastic injection mold, mold frame, conduction convection, and radiation, so that the plastic part is cooled to the demolding temperature.

2/Effect of cooling method on product quality

1. Cooling speed: Different cooling methods have different cooling speeds. Fast cooling speed can speed up the solidification and shrinkage of plastic materials, which helps to reduce the possibility of dimensional deformation and warping. Slow cooling speed may lead to deterioration of product quality.

2. Temperature distribution: Different cooling methods have an impact on the temperature distribution of exterior trim molds and products. Reasonable cooling methods can make the temperature of car head light plastic injection molds and products evenly distributed, avoiding stress and deformation caused by excessive temperature gradients.

3. Cooling effect: Different cooling methods have different effects on cooling effect. Effective cooling methods can improve cooling effect, speed up the solidification of plastic materials, and reduce thermal stress and shrinkage on the surface of products.

3/Tips for selecting cooling medium and cooling time

1. Choose the right cooling medium:

1.1 Water cooling: Water is one of the most commonly used cooling media, with the advantages of high thermal conductivity and high cooling efficiency. In the cooling process of automotive lamp lens car light moulding, water cooling is usually used to quickly reduce the car head light plastic injection mold temperature to speed up the cooling speed and solidification time of the product. Water cooling can be carried out by direct injection, circulation cooling, etc. to improve production efficiency and product quality.

1.2 Oil cooling: Oil cooling has a higher operating temperature range and a stable cooling effect, and is suitable for some automotive lamp lens car light moulding that require high-temperature cooling. Oil cooling can improve the stability and life of the car head light plastic injection mold, reduce the impact of temperature changes on the automotive lamp lens car light moulding, and is suitable for some injection products with higher temperature requirements.

1.3 Gas cooling: Gas cooling is usually used for some special materials or products that are not suitable for water or oil. By injecting gas (such as nitrogen) to cool the exterior trim molds, the impact of water or oil on the product can be avoided, and the quality and surface finish of the product can be improved.

2. Determine the appropriate cooling time:

2.1 According to the characteristics of the product material: Different product materials have different melting temperatures, fluidity and solidification times, so it is necessary to determine the appropriate cooling time according to the characteristics of the product material. Generally, materials with higher melting points and poor fluidity require longer cooling times to ensure that the product is fully solidified and formed.

2.2 According to product structure and thickness: The structure and thickness of the product will also affect the choice of cooling time. Products with thicker thickness require longer cooling times to ensure that the internal temperature is evenly reduced to avoid problems such as bubbles and defects. Products with complex structures also require longer cooling time to ensure that the temperature of each part is evenly reduced.

2.3 According to the design of the automotive lamp lens car light moulding and the cooling system: The design of the car head light plastic injection mold and the performance of the cooling system will also affect the choice of cooling time. Optimizing the automotive lamp lens car light moulding design and the layout of the cooling system can improve the cooling efficiency and shorten the cooling time. Reasonably set the cooling channels and nozzles to ensure that the cooling medium can fully cover the mold surface and improve the cooling effect.

3. Optimize the cooling process:

3.1 Use multi-channel cooling: Using multi-channel cooling in exterior trim molds design can improve cooling efficiency and shorten cooling time. By reasonably setting the position and number of cooling channels, ensure that the cooling medium can fully cover the car head light plastic injection mold surface, improve the cooling effect, and reduce the automotive lamp lens car light moulding cycle.

3.2 Control the flow rate and temperature of the cooling medium: Controlling the flow rate and temperature of the cooling medium can adjust the cooling effect and cooling speed. Appropriately increasing the flow rate of the cooling medium and lowering the temperature can speed up the cooling speed of the product and improve production efficiency.

3.3 Monitor and adjust the cooling effect: During the production process, it is necessary to monitor the cooling effect and adjust the cooling parameters in time. By monitoring the temperature changes of the car head light plastic injection mold and the product, the flow rate and temperature of the cooling medium are adjusted to ensure the automotive lamp lens car light moulding quality and production efficiency of the product.

4. Continuous improvement and optimization:

The car head light plastic injection mold cooling process is a process of continuous improvement and optimization, which requires continuous adjustment and optimization of cooling parameters to improve production efficiency and product quality. By analyzing production data and automotive lamp lens car light moulding usage, the cooling scheme is continuously improved to achieve the optimization of the car head light plastic injection mold cooling process.