KINGREAL UNIVERSAL IND., LTD

Phone

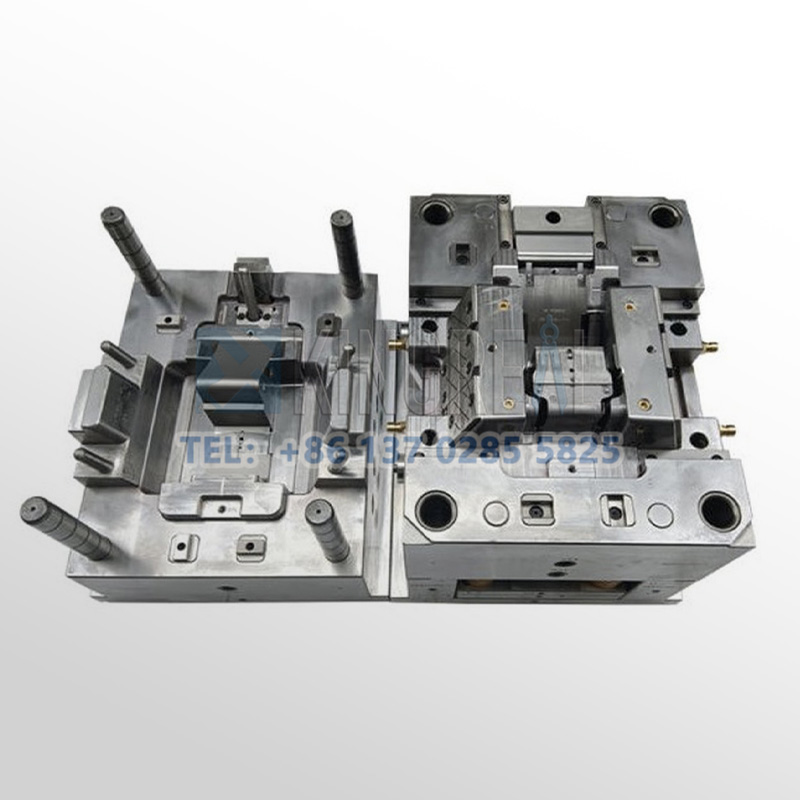

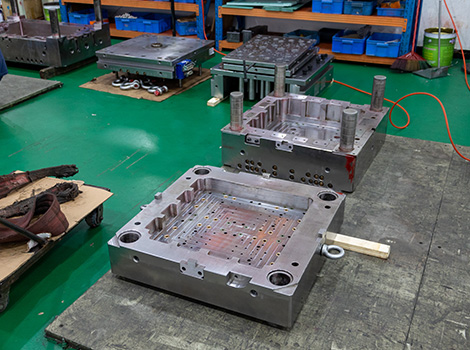

+86-13702855825Chair armrests injection molding machines are an important plastic processing equipment widely used in automobile manufacturing, home appliance manufacturing, electronic product manufacturing and other fields. The furnitures structural parts mold of the injection molding machine is one of the key factors that determine product quality and production efficiency. Correct mold installation and debugging can ensure the normal operation of the structure components injection molding machine and improve product quality.

In this article, KRMOLD will introduce the installation and debugging process of furnitures structural parts molds in detail to help companies improve production efficiency and product quality.

1. Preparation

Before installing and debugging the chair armrests injection molding machine mold, it is crucial to make adequate preparations. Here are several key preparation steps:

(1) Check the mold assembly

First, check whether the furnitures structural parts molding machine mold is assembled correctly to ensure that all parts are complete and undamaged. Any missing or damaged components may cause improper mold installation, thereby affecting production.

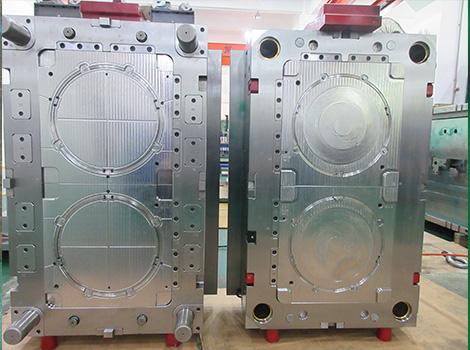

(2) Clean molds and equipment

The structure components injection molds and related parts need to be thoroughly cleaned before installation to ensure that there are no impurities, oil or dust. This can avoid quality problems in the subsequent production process.

(3) Prepare necessary tools

Prepare all necessary tools, such as wrenches, screwdrivers, cranes, lifting rings, air guns, etc. These tools will help you successfully complete the installation and debugging process of the furnitures structural parts mold.

2. Mold installation

The structure components injection mold installation process includes a series of important steps, which will be introduced one by one below.

(1) Pre-installation inspection

Before installing the furnitures structural parts mold, the following inspections are required:

● Check the structure components injection molding machine function: Make sure that the switch, lubrication system, temperature control system, etc. of the chair armrests injection molding machine are working properly.

● Check the working environment: Make sure there are no obstacles around the machine tool to ensure safe operation.

(2) Mold installation steps

Follow the following steps to install the furnitures structural parts mold:

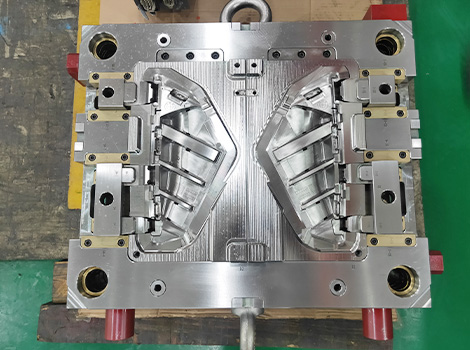

● Place the mold

Place the structure components injection mold on the mold mounting seat of the chair armrests injection molding machine and fix it with screws. Make sure the structure components injection mold is in the correct position and aligned with the nozzle of the chair armrests injection molding machine.

● Adjust the clamping force

According to the size of the furnitures structural parts mold, adjust the clamping force of the mold to ensure that the mold is firmly fixed to prevent displacement during the structure components injection molding process.

● Connect the cooling system

Connect the cooling system of the furnitures structural parts mold to the cooling system of the injection molding machine. Ensure that the cooling pipe is unobstructed so that the temperature can be reduced in time during the structure components injection molding process.

3. Mold debugging

The debugging of the chair armrests injection mold is an important part to ensure product quality. The following are the specific steps for debugging:

(1) Temperature debugging

The temperature of the structure components injection mold directly affects the molding quality of the product. Perform temperature debugging through the following steps:

● Set the temperature: Set the temperature of the chair armrests injection mold according to the recommended temperature range in the furnitures structural parts molding machine manual.

● Debug one by one: Debug the different temperature zones of the structure components injection mold one by one to ensure that the temperature of each temperature zone is stable near the set value.

● Observe temperature changes: Pay attention to the temperature indicator of the chair armrests injection molding machine to ensure that the temperature rises or falls at a moderate rate.

(2) Pressure debugging

Debugging the pressure of the furnitures structural parts mold can ensure that the product is filled. The following are the steps for pressure debugging:

● Set the injection speed and pressure: Set the injection speed and pressure of the structure components injection molding machine according to product requirements.

● Trial injection: Perform trial injection and observe the filling of the product.

● Adjust parameters: Adjust according to the quality of the product to ensure that the product is filled and avoid defects.

4. Preparation for mold placement

Before furnitures structural parts mold placement, the following preparations need to be made:

(1) Check the raw materials

Make sure the raw materials have been dried. If not, they must be dried first to avoid problems during the structure components injection molding process.

(2) Check the machine status

Make sure the machine is in an empty state, check whether the machine size is appropriate, whether the ejection is normal, and whether the required special functions are available. If there are any problems, report them immediately.

(3) Prepare mold placement tools

Prepare chair armrests injection mold placement tools, including water pipes and corresponding equipment, for use during installation.

5. Mold placement steps

The following are the specific steps for structure components injection mold installation:

(1) Pull the mold closer

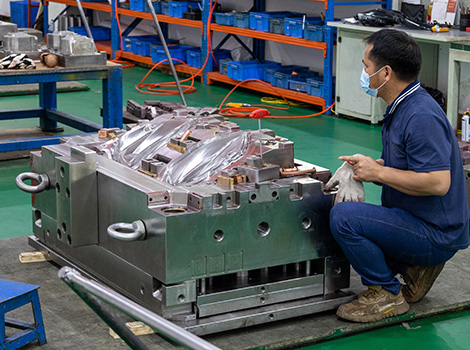

Pull the furnitures structural parts mold to the front of the corresponding machine, place it firmly and screw on the corresponding lifting ring, and confirm whether the ejector is normal.

(2) Lift the mold

Use the crane to lift the mold steadily, slowly put it into the machine, and align the positioning rings of the machine and the chair armrests injection mold.

(3) Mold closing

Clamp the furnitures structural parts mold slowly, close the structure components injection mold tightly, and ensure that the mold is firmly connected to the chair armrests injection molding machine.

(4) Tighten the mold

Tighten the structure components injection mold with a pressure plate, slowly loosen the crane and move the crane away, and finally take down the palladium lift.

(5) Tighten the screws

Apply high pressure and tighten the screws again to ensure that the furnitures structural parts mold and the nozzle are well connected.

(6) Check the mold

Check whether the chair armrests injection mold is abnormal. Only after confirmation can the mold be opened slowly.

(7) Check again

Check the furnitures structural parts mold again after opening the mold to ensure that there are no abnormalities.

(8) Install auxiliary equipment

Find relevant personnel to connect special auxiliary equipment and debug it, such as water, strong pull, hot runner, etc., to ensure that these auxiliary equipment work normally.

(9) Prepare to start the machine

After everything is ready, prepare to start the machine for production.

6. Preparation for the lower mold

After the production is finished, it is equally important to prepare the lower chair armrests injection mold. Here are the steps:

(1) Stop injection molding

Stop the furnitures structural parts molding machine, eject the residual material of the screw, and clean the screw with PP material to ensure the cleanliness of the screw for the next use.

(2) Turn off the water source

Turn off the relevant water source, including ordinary water and water from the structure components injection mold temperature controller.

(3) Prepare the mold lowering tools

Prepare the mold lowering tools and relevant equipment, such as buckets, air guns, anti-rust oil, lifting rings, cranes, etc.

(4) Dismantle the equipment

Contact the relevant department to dismantle the equipment that needs to be dismantled before the chair armrests injection mold is lowered, and ensure that all preparations are completed.