KINGREAL UNIVERSAL IND., LTD

Phone

+86-13702855825In the broad field of modern manufacturing, plastic injection molds are everywhere, and they play an indispensable role in everything from common household appliances to precision automobile parts to daily plastic products. The quality of storage boxes injection mold directly determines the quality of the final product. Therefore, in the whole process of plastic storage boxes injection mold manufacturing, implementing strict and comprehensive quality control has become the core move to improve product quality and meet market demand.

Today, KRMOLD will take you to understand the key points and practical strategies that determine the quality of functional accessories injection molds.

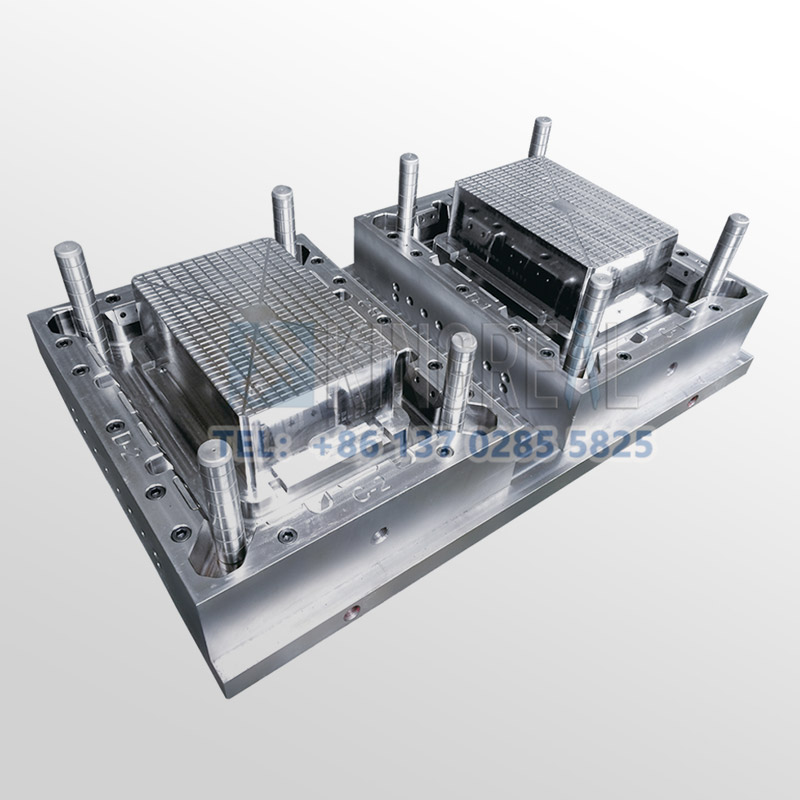

(1) Design of functional accessories injection mold

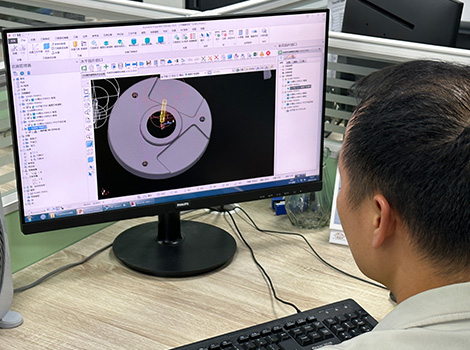

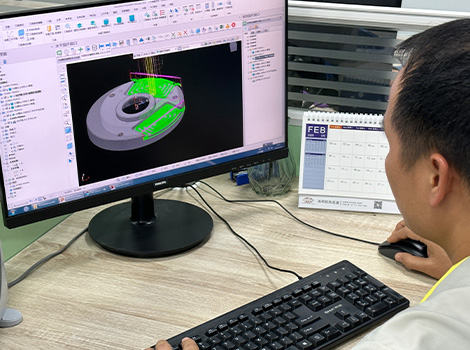

As the opening chapter of plastic storage boxes injection mold manufacturing, plastic storage boxes injection mold design is also the source of quality control. An excellent storage boxes injection mold design should not only perfectly meet the functional demands and aesthetic appearance of the product, but also deeply consider the feasibility of the manufacturing process, the durability of the functional accessories injection mold itself and the convenience of subsequent maintenance.

With the help of advanced technology: using efficient design software such as CAD (Computer Aided Design) and CAE (Computer Aided Engineering), the plastic storage boxes injection mold flow analysis and thermal analysis are carried out. By simulating the flow state and temperature distribution of plastic in the storage boxes injection mold, the potential problems can be predicted and solved in advance, the functional accessories injection mold structure can be optimized, and the risk of defects in the later production can be greatly reduced. For example, when designing a complicated functional accessories injection mold for automotive plastic interior parts, CAE analysis found that the weld line position was not ideal. After adjusting the gate position and number, the defect was successfully eliminated and the product quality was improved.

Precise tolerance setting: In the design process, it is necessary to fully consider the accuracy limitation of mechanical processing and the shrinkage characteristics of plastic in the storage boxes injection molding process, and set the tolerance range scientifically and reasonably. This ensures that all parts of the plastic storage boxes injection mold can be accurately matched, avoids assembly problems caused by dimensional deviation, and lays a solid foundation for efficient operation of the plastic storage boxes injection mold. For example, when designing the shell plastic storage boxes injection mold of small electronic equipment, the tolerance is accurately controlled, so that the parts of the plastic storage boxes injection mold are tightly assembled, and the molded product has accurate dimensions and seamless appearance.

Strengthen maintainability: The maintainability of the functional accessories injection mold should be taken into consideration in the design stage to ensure that in the long-term use process, once problems occur, it can be repaired or replaced quickly and conveniently. For example, by adopting the modular design concept, the functional accessories injection mold is divided into several independent modules, and when a certain module fails, it can be replaced directly, without large-scale disassembly of the whole plastic storage boxes injection mold, which effectively shortens the downtime and reduces the maintenance cost.

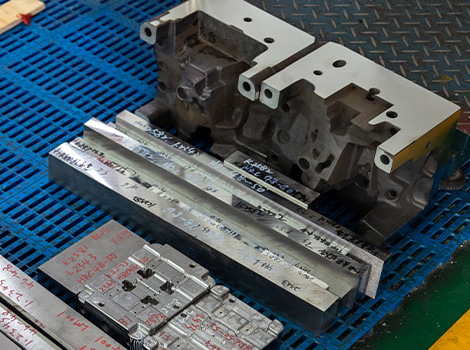

(2)Strictly select mold materials

The choice of die material directly determines the performance and service life of the plastic storage boxes injection mold. Therefore, selecting suitable materials according to actual needs plays a decisive role in ensuring the quality of functional accessories injection molds.

Suitable for use scene: according to the specific requirements of the product and the actual working environment of the storage boxes injection mold, select materials with sufficient strength, hardness, corrosion resistance and wear resistance. For example, the materials used to make food packaging molds should not only have good formability, but also meet food hygiene and safety standards to ensure non-toxic and harmless; The functional accessories injection mold used for injection molding high-temperature plastic products needs to choose materials with excellent heat resistance to ensure that the functional accessories injection mold can still work stably in high-temperature environment.

Balance cost-benefit: on the premise of meeting the performance requirements, comprehensively evaluate the cost-benefit of materials. The higher the price, the better the material is, but the cost should be controlled reasonably while ensuring the quality of the plastic storage boxes injection mold. By analyzing and comparing the cost performance of different materials, the materials that can meet the production demand and keep the storage boxes injection mold cost in a reasonable range are selected to achieve a win-win situation of economic benefits and product quality.

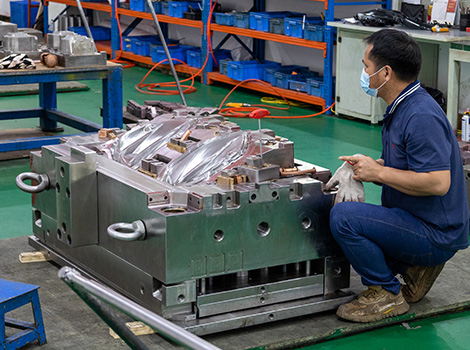

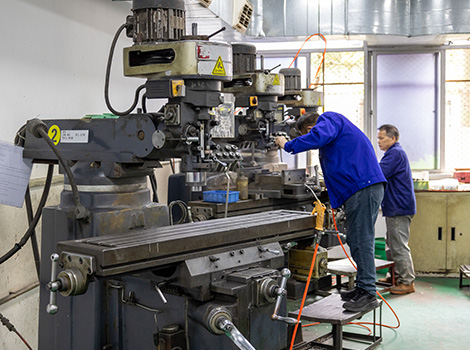

(3)Control the mold processing process

The processing process is the core link of plastic storage boxes injection mold manufacturing, just like a craftsman carving a work of art, its fineness is directly related to the final quality of the functional accessories injection mold.

Standardize operation behavior: elaborate scientific and reasonable process flow, define the operation norms and quality standards of each process, and minimize the interference of human factors on quality. For example, in the cutting process of die parts, the selection of tools, the setting of cutting parameters and the processing sequence are stipulated to ensure the consistency and stability of the processing process, thus ensuring the processing accuracy of parts.

Regular maintenance of equipment: regular comprehensive and meticulous maintenance of processing equipment, including equipment cleaning, lubrication, calibration and inspection and replacement of key components. Make the equipment always in the best running state, which can not only improve the machining accuracy, but also effectively prolong the service life of the equipment and improve the production efficiency. For example, the high-precision CNC machining center is calibrated regularly to ensure that the dimensional accuracy of the machined mold parts always meets the requirements.

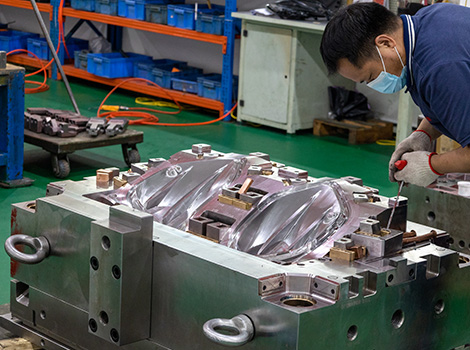

(4)Inspection and evaluation mold

Inspection and evaluation is a solid line of defense to ensure the quality of storage boxes injection molds. Through strict and scientific inspection means and evaluation standards, problems can be found and corrected in time and accurately, thus ensuring the quality of plastic storage boxes injection molds.

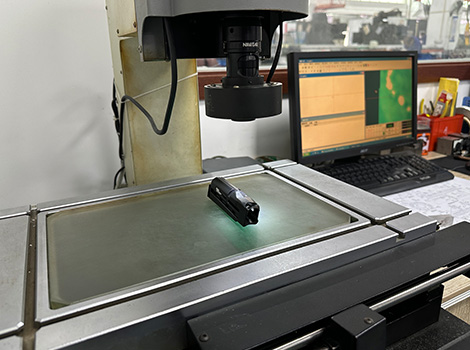

Enrich detection means: develop diversified and scientific detection methods, covering dimensions such as size detection, performance test and appearance detection. Using high-precision measuring instruments to accurately measure the dimensions of the die parts, testing the performance of the functional accessories injection mold by simulating the actual working conditions, and carefully checking whether there are defects on the surface of the functional accessories injection mold, so as to ensure that the die meets the design requirements in an all-round way. For example, the size of the mold cavity is measured by a three-coordinate measuring instrument, and the error is controlled within a very small range; The demoulding performance of the plastic storage boxes injection mold was actually tested to ensure that the product could be demoulded smoothly.

Establish evaluation criteria: Establish clear evaluation criteria to quantitatively evaluate various quality indicators of storage boxes injection molds. This provides a precise direction for the improvement of mold quality, which is convenient for enterprises to take targeted improvement measures. For example, the allowable deviation range of dimensional accuracy of die parts, the quantitative standard of surface roughness and the evaluation index of die service life are formulated, and the quality of die is directly reflected through data.

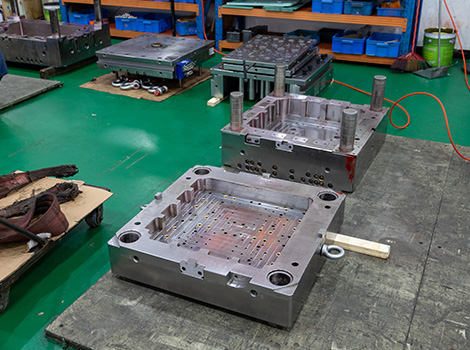

(5)Maintain the storage boxes injection mold

Maintenance is the key to ensure the long-term stable operation of functional accessories injection molds, and regular maintenance can significantly extend the service life of storage boxes injection molds.

Regular inspection: conduct a comprehensive and in-depth inspection of the plastic storage boxes injection mold according to the established cycle, including the structural integrity of the mold, the wear of parts, the patency of the cooling system, etc. Discover and repair potential problems in time to prevent minor faults from turning into major accidents. For example, check the ejector pin system of the functional accessories injection mold regularly to ensure that the ejector pin is free from jamming and wear, and to avoid poor ejection of products due to ejector pin failure.

Regular maintenance: elaborate a detailed and reasonable maintenance plan, covering daily maintenance work such as mold cleaning, lubrication and fastening. Regularly clean the functional accessories injection mold to remove oil stains and impurities on the surface; Lubrication of moving parts to reduce friction resistance; Fasten the connection parts to prevent looseness. Through continuous maintenance, the plastic storage boxes injection mold is always kept in the best running state. For example, lubricate the guide post and guide sleeve of the storage boxes injection mold every week, and thoroughly clean and fasten the storage boxes injection mold once a month.