KINGREAL UNIVERSAL IND., LTD

Phone

+86-13702855825"Automotive lighting molds are an important component that must exist in the automotive lighting Injection molding process. Choosing the right automotive lamp lens car light moulding is essential to ensure product quality, performance, and cost-effectiveness. This article will provide you with a detailed introduction to the key considerations when choosing automotive lighting molds manufacturer to help you make an informed decision."

1/ Impact of poor quality automotive lighting molds

Poorly made automotive lamp lens car light mouldings can lead to more product defects, reduced production efficiency, and other problems. We should ensure that the mold design is reasonable, high-quality materials are selected, and process control is strengthened to improve the mold making level.

Automotive lighting molds are key tools in the production process of plastic products, and their quality directly affects the quality and production efficiency of the product. If the automotive lamp lens car light moulding is not made properly, it may cause the following series of problems.

1. More product defects: Irregular mold making may cause defects such as deformation, shrinkage, and bubbles in the product, affecting the appearance and performance of the product.

2. Reduced production efficiency: Insufficient automotive lamp lens car light moulding making precision may lead to frequent automotive lighting molds adjustments during production, reducing production efficiency. At the same time, the short mold life will also increase the frequency of automotive lamp lens car light moulding replacement, further affecting production efficiency.

3. Increased costs: Improper automotive lighting Injection molding making may lead to problems such as waste of raw materials and increased labor costs, which in turn increase production costs.

2/Tips for choosing automotive lighting molds manufacturer

1. Professional ability

First, you need to conduct a 360-degree inspection of the automotive lamp lens car light moulding factory to see whether it is a one-stop automotive lighting Injection molding manufacturer and whether it has the ability to provide one-stop services from mold design and manufacturing, product automotive lamp lens car light moulding, plastic shell surface treatment (spraying, silk screen, etc.). The main purpose is to examine whether its professional ability is sufficient to support the subsequent mass production. Many factories can only engage in a certain link of automotive lighting Injection molding, and the rest will be transferred for a second time. In this way, many of the subsequent landing links are completely out of control, which buries many risks.

2. Corporate culture

Corporate culture is something that most people tend to overlook. In fact, if the hardware of various automotive lamp lens car light moulding factories is compared, there will not be much difference between the same echelon. On the contrary, there are big differences in corporate culture, rules and regulations, team spirit, etc. If an automotive lighting Injection molding factory has a good corporate culture, then they must have a clear mission, values and way of doing things, and the work process is often done very carefully, which is much better than the conventional superficial management system.

3. Service capability

There is no need to say more about this. The service of the automotive lighting Injection molding factory is not only pre-sales, in-sales, and after-sales. It is not just about whether the delivery can be made on time. The more important thing is to perceive the needs of customers in advance and be able to do the work in advance to avoid problems. If you encounter a problem, you must be able to respond quickly, not passively deal with it, but actively cooperate to solve the problem, seek the most appropriate way and be willing to optimize your own process system.

4. Quality test

Maybe you have talked about good things, but you must conduct a small sample test. First, according to the pre-set goals, the automotive lighting Injection molding factory is required to provide proofing services. Through this link, the production quality of the automotive lamp lens car light moulding factory can be basically tested. If the effect of the sample link is not very satisfactory, then the subsequent bulk goods will basically be worse. Therefore, the proofing test link is the last layer of insurance mechanism, and it must be carefully examined.

5. Cost-effectiveness

The cost-effectiveness is placed at the end. Generally, small manufacturers will negotiate prices with you. If you want to find a reliable automotive lighting Injection molding factory, this link is generally placed at the end. When you find an automotive lamp lens car light moulding factory that meets the previous links, you will generally find two or so to compare quotations. Through the final comparison of region, price, service, etc., you can basically find the automotive lighting molds factory that best suits you.

3/Advantages of KRMOLD

★Quality Assurance

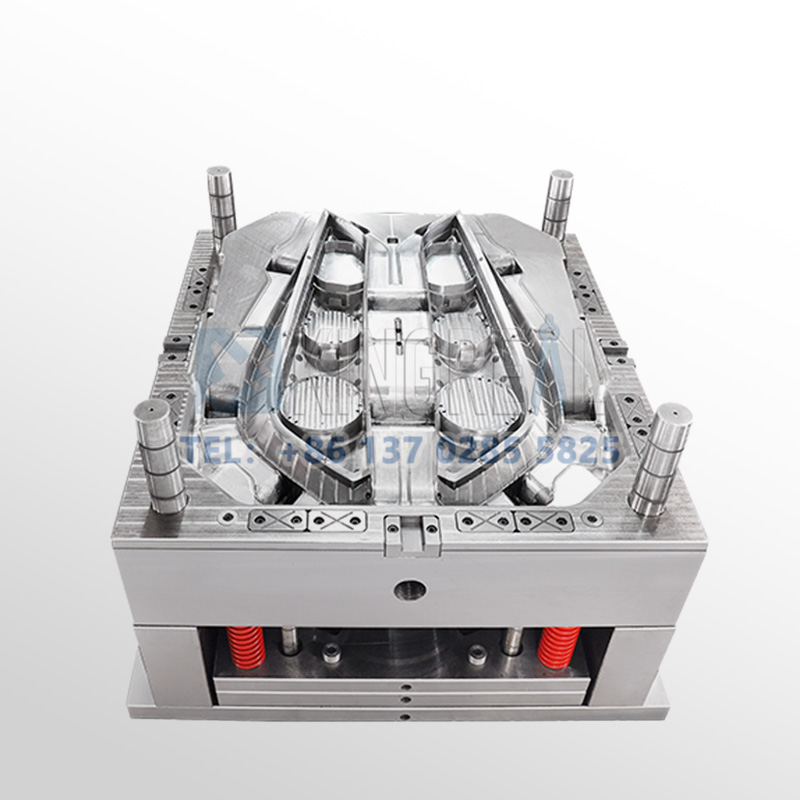

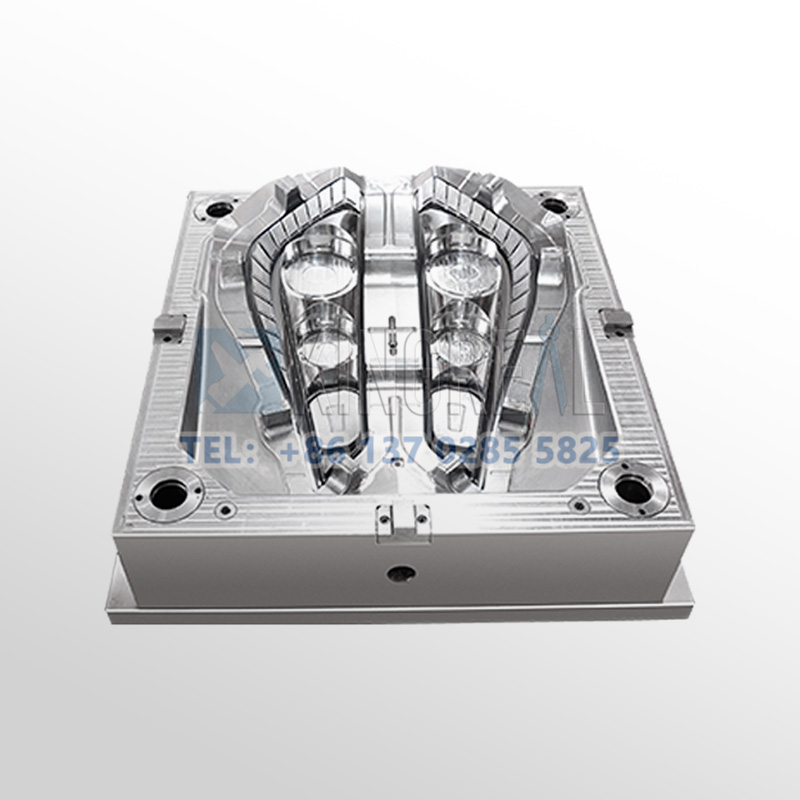

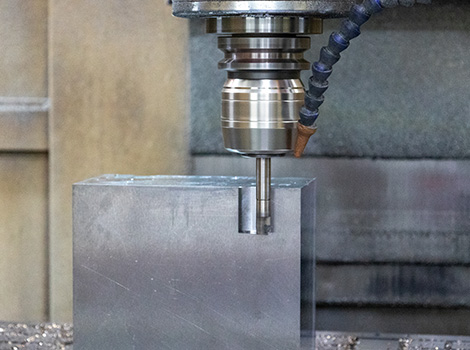

In the manufacturing process of automotive lamp lens car light mouldings, KRMOLD uses high-end equipment from well-known domestic and foreign brands. These equipment have been strictly screened to ensure that the produced automotive lighting molds have excellent quality. To further ensure the reliability of the product, KRMOLD is equipped with a number of advanced quality inspection equipment. After the automotive lighting molds is manufactured, each mold will undergo multiple levels of testing to ensure that it meets the standards. Through this strict quality control process, KRMOLD is able to provide customers with high-quality automotive lamp lens car light mouldings to meet their usage needs.

★Guaranteed delivery time

As a automotive lamp lens car light moulding manufacturer with nearly 20 years of experience, KRMOLD has accumulated rich expertise and good reputation in the industry. KRMOLD not only has strong production strength, but also always adheres to the principle of integrity to ensure timely delivery. Regarding the delivery time of automotive lighting molds, KRMOLD will strictly follow the time agreed in the contract. KRMOLD always takes the customer's production plan as the priority and will not delay the delivery date to avoid affecting the customer's production progress.

★Provide trial mold modification

During the automotive lamp lens car light moulding manufacturing process, KRMOLD will design and produce according to the specific parameters provided by the customer, and provide trial mold services after completion. If the finished product is found to be inconsistent with the preset parameters during the mold test, KRMOLD will immediately adjust and modify it to ensure that the final product fully meets the customer's needs. KRMOLD attaches great importance to customer feedback, continuously improves, and strives to provide the best solutions to ensure customer satisfaction.