KINGREAL UNIVERSAL IND., LTD

Phone

+86-13702855825You need to choose a good manufacturer for theagricultural machinery injection mold, which consumes time and cost. In this article, KRMOLD will analyze from 6 indicators how to find a qualified agriculture injection molding factory.

The 6 indicators for finding a agriculture plastic injection molding factory include: product demand, integration, technical capabilities, environmental equipment, quality management, and follow-up services.

| 1 | Product demand |

| 2 | Integration |

| 3 | Technicality |

| 4 | Quality management |

| 5 | Environmental equipment |

| 6 | Subsequent service |

(1) Product demand

Clarify product demand Product demand is the focus of all subsequent indicators. If you don’t know your product demand, it is easy to go in the wrong direction and find an unsuitable manufacturer. Because plastic products can be subdivided into many types, and each manufacturer is good at different things, there are functional parts, appearance parts, whether to post-process, printing or inlaying other materials, etc. ... Like general appearance parts, they only require good looks, do not require precise agriculture injection molding manufacturing, do not need to cooperate with other components for processing, and the technical requirements are relatively simple, such as: plastic boxes, trash cans and other products; while if it is a functional and precise plastic part, the technical requirements are relatively high, such as airtight valves, perfume spray eye products and other products. Only by knowing the product requirements can you find an agriculture plastic injection molding factory with corresponding price and technology. KRMOLD has cooperated with customers in the medical industry, home appliances, automotive industry and other fields to produce a large number of functional and precise products.

(2) Integration

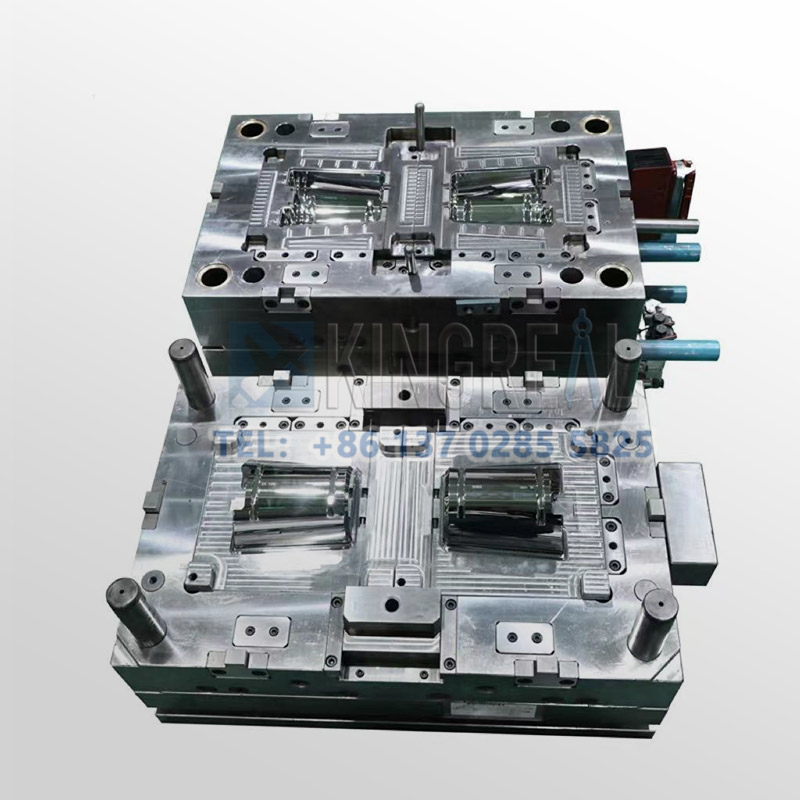

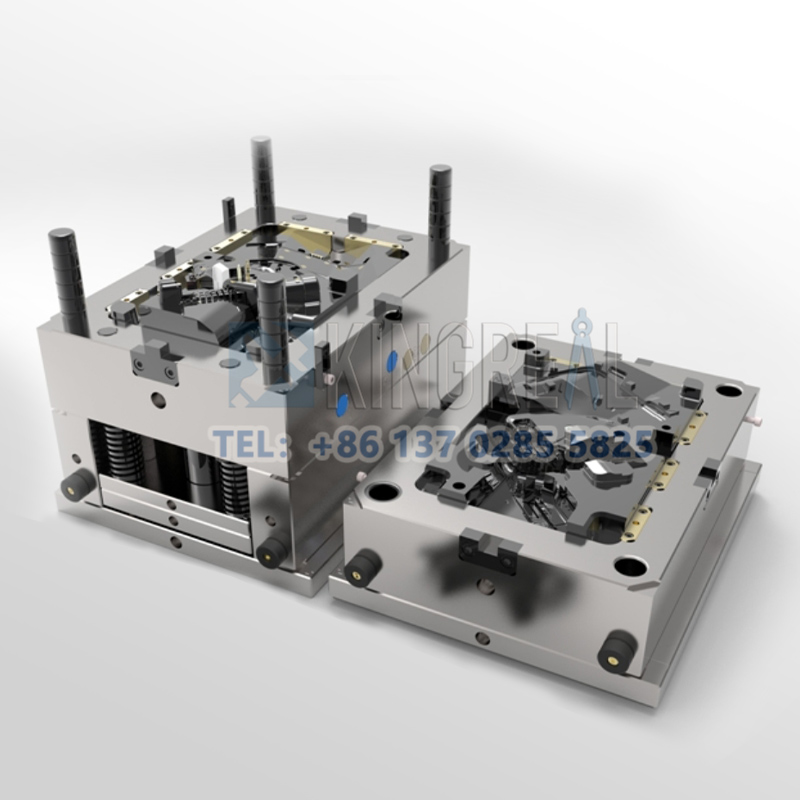

Looking for a one-stop service OEM factory to find an agriculture injection molding factory or an agriculture plastic injection molding factory? If there is a problem with the product, will you blame each other and end up suffering the loss? If there is no stable cooperative factory at present, it is recommended that you directly find a agricultural machinery injection mold supplier like KRMOLD that can provide one-stop service. In addition to helping you save the cost of intermediate communication and transportation, the advantage of finding a one-stop service is that "from agricultural machinery injection mold design and manufacturing to agriculture plastic injection molding, it can be solved in one stop". Even after the product is mass-produced, the agricultural machinery injection mold needs to be repaired and completed in one stop.

(3) Technicality

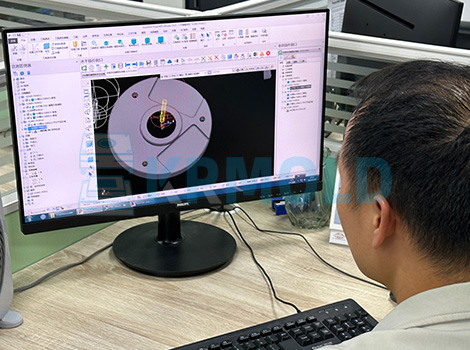

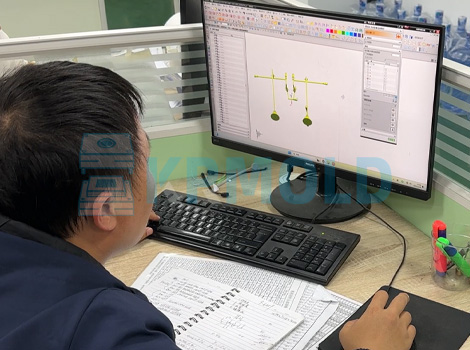

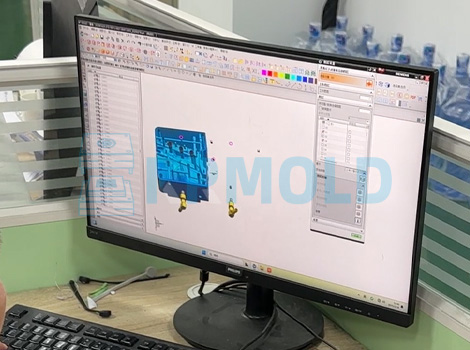

Agricultural machinery injection mold and agriculture injection molding of technology lies in the adjustment of parameters, but if the agricultural machinery injection mold is developed incorrectly at the very beginning, it is actually difficult to remedy it. Because the process of agriculture plastic injection molding is like making egg cakes, if the tail of Pikachu in the agricultural machinery injection mold pattern is short, even if the raw materials of the egg cake are filled and overflowed, it is difficult to make a beautiful tail, and it will also prolong the entire manufacturing time or shorten the life of the agricultural machinery injection mold. In practice, there is no difference in appearance between the agriculture plastic injection molding made by a novice and the agriculture injection molding made by an old master. The truth can only be seen through the mold closing and actual agriculture injection molding of the finished product. Therefore, when looking for a agriculture plastic injection molding factory, evaluating the manufacturer's past experience and the machines used are very important indicators. Because the technology of the agriculture injection molding includes mold cavity design, runner design, slider mechanism, mold material, etc., which are all accumulated experience. Going to the site to see whether the maintenance is implemented and listening to the manufacturer's processing experience can help you understand.

(4) Quality management

Basic inspection instruments such as vernier calipers, micrometers, microscopes, two-dimensional, three-dimensional, etc. are essential for general agriculture plastic injection molding factories, but if functional products are produced, it is necessary to test whether the finished products meet the airtight pressure standards according to product requirements. Different products have different airtight pressure standards. For example, the airtight pressure standard of gas bottles is higher, because if the bottle body breaks, it will cause the risk of product explosion, which greatly affects the function and safety of the product. Therefore, if the agriculture injection molding factory you find does not have testing equipment and cannot do functional testing, you can only do airtight inspection after the goods are delivered to you. When the quality is wrong, the entire batch of goods may need to be returned, and the time and cost of going back and forth are quite large, so the best situation is to "cooperate with an agriculture injection molding factory with relevant inspection machines". When production problems occur, the agriculture plastic injection molding factory can immediately eliminate the problem. KRMOLD has many well-known domestic and foreign brands of inspection equipment, which can well guarantee this.

(5) Environmental equipment

If you want to produce medical-grade products, you need to choose a plastic injection molding factory with a clean room or dust-free room. The presence or absence of this environment has become the basic standard for selecting manufacturers. There are also differences in the level of clean rooms, depending on which country's standards are adopted; in terms of equipment, injection molding machines are also divided into hydraulic and all-electric types. All-electric machines rely on servo motors and electricity to operate, which are less likely to cause oil pollution and meet the conditions of medical products. Machines with higher hydraulic power are suitable for producing large molds.

(6) Subsequent service

If the product is developed for the first time, there may be subsequent design changes, mold parts maintenance after mass production, etc., so you should also consider whether the agriculture plastic injection molding factory you are looking for has a mold warranty, the cost of each maintenance, and whether the price is reasonable. If you refer to the previous suggestions and directly find an integrated manufacturer, the agricultural machinery injection mold can be repaired directly in the factory, which is convenient for you and saves costs. Moreover, this type of manufacturer will do a better job in the first production because they also do the subsequent repairs themselves. KRMOLD can provide agriculture plastic injection molding trial services. After the agricultural machinery injection mold is produced, it will be tested with multiple devices and put into the injection molding machine for testing. If it cannot meet the customer's requirements, KRMOLD will modify the parameters again. And it will be completed and shipped within the specified construction period.