KINGREAL UNIVERSAL IND., LTD

Phone

+86-13702855825| 1 | Overview of Plastic Chair Injection Mold Production and Processing |

| 2 | FAQ about Plastic Chair Injection Mold |

High-quality plastic chair injection molds can produce strong, smooth chairs in the shortest possible time.

So, how are these plastic chair injection mould actually made? This article will provide a detailed explanation of the production and processing techniques for plastic injection chair molds.

1. Overview of Plastic Chair Injection Mold Production and Processing

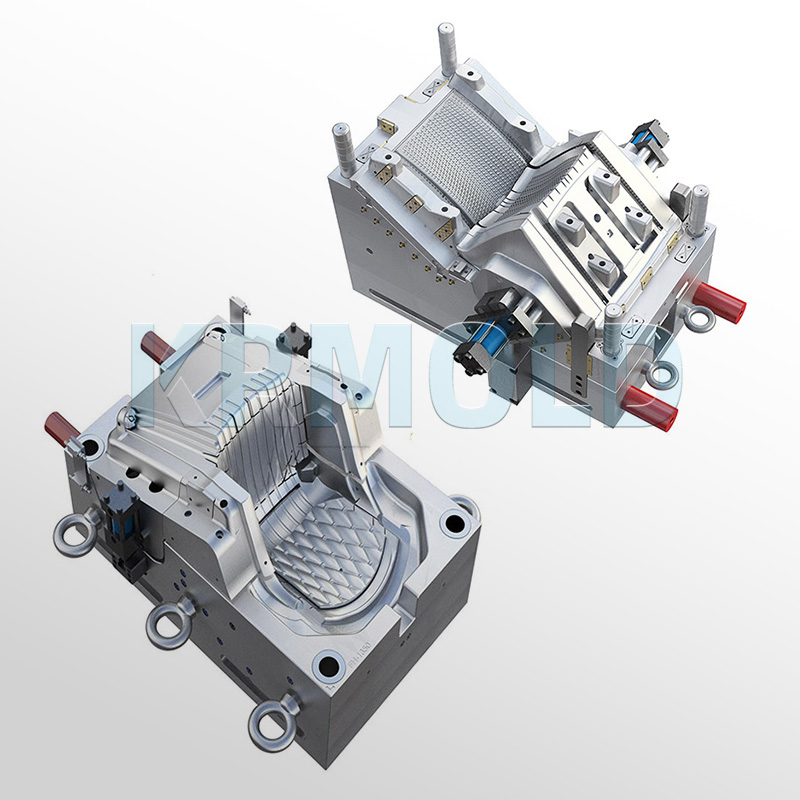

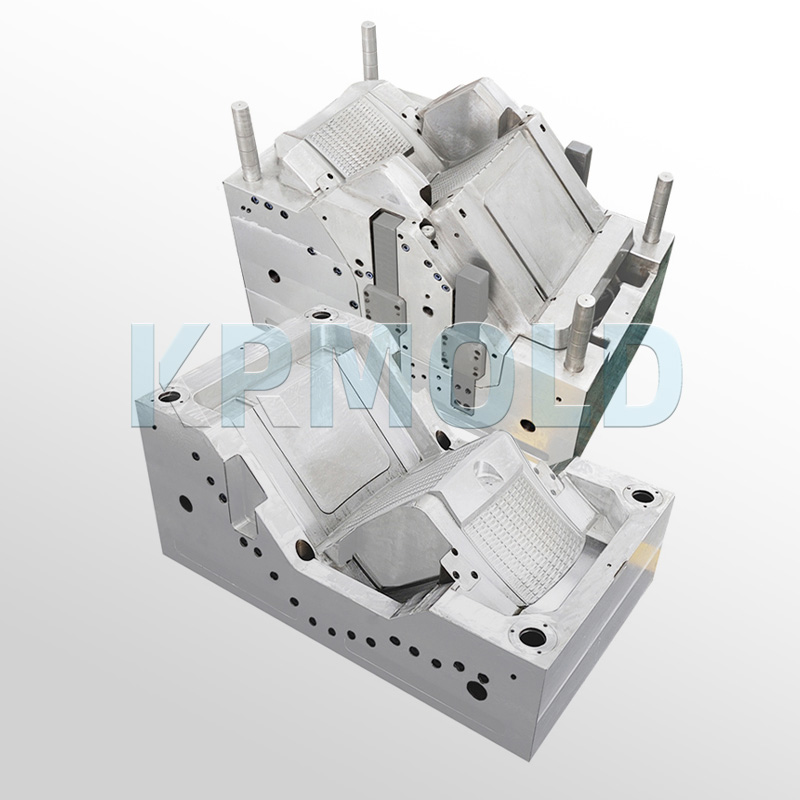

An important stage in the manufacturing process, plastic chair injection mould directly affect the finished quality of the chair. Principally encompassing mold design, manufacture, commissioning, operation, and maintenance, the creation and processing of plastic chair injection molds include mold construction.

1.1Mold Design

Mold design is the first step in the production and processing of plastic chair injection mould. Manufacturing, commissioning, and operational performance of the plastic injection chair mold all depend on design quality.The following features need close attention during plastic chair injection mould development:

Suitable plastic injection chair mold architecture is created depending on the structural properties of the plastic chair to guarantee aesthetic quality and dimensional accuracy.Good structural design helps to cut down material waste and boost production efficiency.

Understanding the characteristics of various plastic materials—melting point, fluidity, shrinkage, and so on—gives a scientific basis for mold design.Performance of the material throughout plastic chair injection moulding depends straightly on these properties.

Choose the right mold shape and sizes based on the injection molding machine's performance to guarantee a seamless fit between the plastic injection chair mold and the equipment, so preventing pointless production failures.

Production Cost: While ensuring product performance, minimize mold design costs. By optimizing the design and reducing unnecessary complexity, production costs can be effectively reduced.

1.2 Plastic Chair Injection Mold Manufacturing

Mold manufacturing primarily involves the following aspects:

To guarantee the wear resistance, corrosion resistance, and longevity of the plastic chair injection mould, choose high-quality plastic chair injection mould materials like steel and alloys.Commonly used mold materials include P20 and H13, which provide great mechanical and processability.

To guarantee mold accuracy and surface finish, use modern machining techniques like CNC machining and EDM. EDM is appropriate for the production of complex forms, while CNC machining allows for high-precision component processing.

To guarantee total plastic chair injection mould performance, exactly fit all mold parts. Particular care must be taken with component fit during assembly to prevent issues throughout the plastic injection chair molding process.

1.3 Mold Adjustment

An essential phase in the manufacture of plastic chair injection molds, plastic chair injection mold correction mostly coverages:

Installing the plastic chair injection mold onto the injection molding machine guarantees exact fit between the mold and the apparatus. Ensure smooth manufacturing by meticulously inspecting the mold's securement during installation.

Injection molding of plastic chairs parameters—temperature, pressure, speed—based on the plastic material's properties and production needs is the modification. Proper adjustment of these parameters is crucial to ensuring uniform filling of the plastic chair injection mold with the plastic material.

Product Inspection: Inspecting finished products after adjustment to ensure that each chair meets quality standards. This step allows for timely identification and resolution of issues, ensuring smooth production.

1.4 Mold Use and Maintenance

Mold Use: Proper use of the plastic chair injection mould is crucial in the production of plastic chairs. Operators must be familiar with plastic chair injection mold handling to avoid damage caused by improper operation.

Mold Maintenance: Regularly inspect, clean, and lubricate the plastic chair injection mould to extend its lifespan. Proper maintenance can effectively reduce mold wear and keep it in good working condition.

2. FAQ about Plastic Chair Injection Mold

(1)How do I choose the appropriate mold material when designing plastic injection chair mould?

Selecting a mold material calls for careful consideration of thermal stability, corrosion resistance, wear resistance, and processing performance.Steel, alloys, copper, and aluminum are among typical mold materials. Selecting the proper material can enhance the lifespan of the plastic injection chair mold and the quality of the final result.

(2)How do I ensure plastic chair injection mould processing accuracy?

Advanced processing techniques like EDM and CNC machining can significantly increase plastic chair injection mould processing accuracy.Regular plastic injection chair mold examination and calibration are also necessary to guarantee precision.

(3)How do I adjust injection molding parameters when trialing a plastic chair injection mould?

Depending on the features of the plastic substance and production needs, change injection molding parameters including temperature, pressure, and injection speed.Correct parameter settings guarantee even filling of the plastic material inside the plastic chair injection mold, hence boosting product quality.

(4)How do I maintain the plastic chair injection mold during use?

Ensure perfect performance by frequently inspecting, cleaning, and lubricating the plastic chair injection mould. Keeping the plastic chair injection mould clean and lubricated properly prolongs its life and lowers the chance of failure.

(5)How can I reduce the production cost of plastic chair injection mould?

Reducing manufacturing costs can be achieved by simplifying the plastic injection chair mold structure, perfecting the design, and choosing suitable materials while also guaranteeing product performance.Reducing expenses also depends on reasonable production process and improved efficiency.