KINGREAL UNIVERSAL IND., LTD

Phone

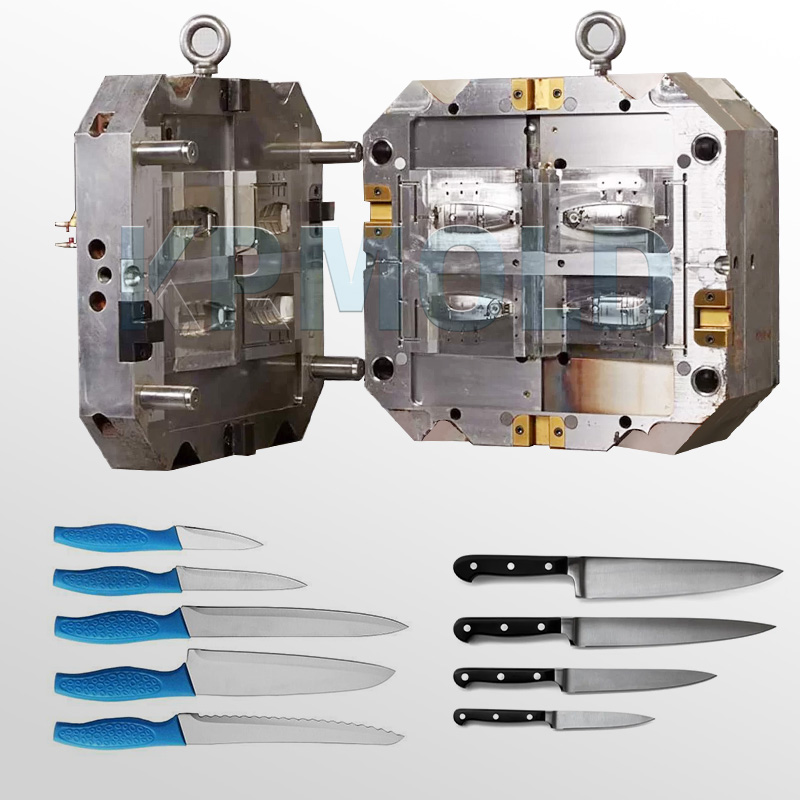

+86-13702855825Knife handle injection molds are used to produce knife handles, which, when combined with blades, form a complete knife. The handle plays a crucial role in these tools, not only providing a comfortable grip for the user but also ensuring safety and stability during use. Knives have widespread applications in daily life, being an important component in kitchens, tools, and many other fields. Therefore, the demand for plastic knife handle mould is increasing year by year, becoming a focus of attention for many related industries.

Many customers preparing to purchase knife handle injection molds are most concerned about the question, "How much do plastic knife handle mould cost?" Next, KRMOLD will discuss in detail several major factors affecting the price of knife handle injection molds and analyze the reasons behind them.

Factors Affecting the Price of Knife Handle Injection Molds

Plastic Knife Handle Mould Material Costs

The cost of materials for plastic knife handle mould is one of the key factors affecting the price. Material costs can be divided into several categories: main materials, auxiliary materials, and heat treatment materials.

Main material costs: The main materials for knife handle injection molds usually use specialized mold steel. These materials have very high requirements for wear resistance and heat resistance, so their price is relatively high. The main components of the plastic knife handle mould, such as the mold base, moving mold core, fixed mold core, and electrodes, are all important parts of the main materials. High-quality mold steel ensures the stability and durability of the knife handle injection mold during long-term use.

Auxiliary material costs: Compared with the main materials, the cost of auxiliary materials is relatively low. Auxiliary materials include ejector pins, bushings, and other assembly materials, as well as water jackets and standard parts. Although these materials are not expensive, they still account for a certain proportion of the overall cost.

Heat treatment materials and process costs: Heat treatments such as quenching and nitriding may seem inexpensive, but they are crucial steps in ensuring the performance and durability of the plastic knife handle mould. In the long run, the accumulated costs should not be underestimated.

Knife Handle Injection Mold Design Costs

The design cost of plastic knife handle mould is also an important factor affecting the overall price. This mainly includes scanning and measurement, structural design, and CAE analysis costs:

Plastic knife handle mould scanning and measurement costs: In the absence of complete drawings, using scanning and measurement technology to model existing products is a necessary step. The specific amount of this cost varies depending on the complexity of the product.

Knife handle injection mold structural design fee: Plastic knife handle mould structural design is an indispensable part. Designers need to design each structure according to the actual needs of the knife handle, forming a complete knife handle injection mold drawing. The higher the complexity, the higher the design cost will be.

Plastic knife handle mould CAE analysis fee: Although CAE analysis is not a mandatory step, performing a reasonable analysis is very valuable because it ensures the rationality and manufacturability of the knife handle injection mold design. If this step is neglected, the final manufactured plastic knife handle mould may have problems, resulting in extremely high repair costs and unnecessary waste.

Knife Handle Injection Mold Processing Costs

Processing costs are the most important part of the knife handle injection mold manufacturing process, usually including:

Machine tool processing for plastic knife handle mould: Large machine tools and CNC machine tools are used for preliminary processing to ensure the basic contour of the knife handle injection mold.

Precision machining for plastic knife handle mould: EDM, wire cutting, and other precision machining processes ensure the detail accuracy of the knife handle injection mold. Fitter and polishing processes ensure the smoothness and appearance of the plastic knife handle mould.

Other costs

In addition to material, design, and processing costs, other aspects will also incur certain costs, such as:

Management fees: Enterprises inevitably incur management-related costs during their operation. This part of the cost indirectly reflects the enterprise's management level.

Transportation costs: After the mold is manufactured, transportation to the customer or other locations also incurs costs.

Mold trial costs: After production is completed, mold trial is an important step to ensure plastic knife handle mould performance, and knife handle injection mold trial costs are unavoidable.

The high manufacturing cost of knife handle injection molds is fundamentally due to their highly customized nature. Each set of knife handle injection molds is "tailor-made" for a specific tool, making mass production difficult. The shape, size, and precision requirements of different tools vary, and the design and processing of the plastic knife handle mould must be adjusted specifically according to the specific requirements, therefore, costs cannot be reduced through large-scale production.

At the same time, plastic knife handle mould production is a technology-intensive and capital-intensive industry. Enterprises must continuously invest in R&D, equipment, and talent to adapt to the ever-changing market demands. This is also one of the reasons why the price of knife handle injection molds is relatively high. As the saying goes, "you get what you pay for." The higher price of knife handle injection molds is justified. The cost of manufacturing a high-performance knife handle injection mold is truly insignificant compared to the value it brings.

If you need more information about plastic knife handle mould or have any questions, please feel free to contact KRMOLD. KRMOLD will be happy to provide you with professional consultation and services. KRMOLD hope this article has helped you gain a preliminary understanding of the pricing of knife handle injection molds.