KINGREAL UNIVERSAL IND., LTD

Phone

+86-137028558251/Definition of turbocharger housing mold

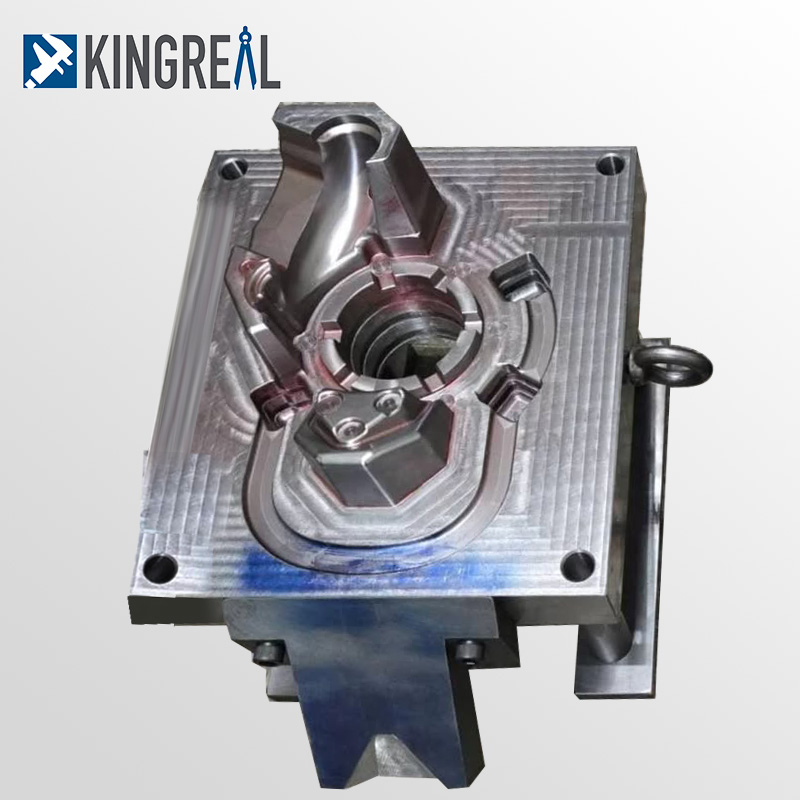

The mold used for plastic turbocharger housing molding is called turbocharger compressor housing mold. Turbocharger houcompressorsing molds can form plastic products with complex shapes, high dimensional accuracy or with inserts in one go.

"70% mold, 30% process". For turbocharger houcompressorsing molding, the turbocharger compressor housing mold has a great influence on the quality of the molded product, just like the plastic turbocharger housing molding machine. It can even be said that the turbocharger housing mold plays a greater role than the turbocharger houcompressorsing molding machine. If you do not fully understand the turbocharger housing mold during plastic turbocharger housing molding, it is difficult to get a good molded product.

2/Structure of turbocharger housing mold

The structure of the turbocharger compressor housing mold is determined by the type of plastic turbocharger housing molding machine and the structural characteristics of the plastic part. Each mold consists of a movable mold and a fixed mold. The movable mold is installed on the movable plate of the turbocharger houcompressorsing molding machine, while the fixed mold is installed on the fixed plate of the plastic turbocharger housing molding machine. During turbocharger compressor housing molding, the movable mold and the fixed mold are closed to form a pouring system and a cavity. When the turbocharger compressor housing molds are separated, the plastic part or beer part remains on the movable mold side, and then the demolding mechanism set in the movable mold ejects the plastic part. According to the different functions of each component in the turbocharger housing mold, a set of turbocharger compressor housing molds can be divided into the following parts:

1. Molding parts

Parts that give the turbocharger houcompressorsing molding material shape, structure, and size, usually composed of cores (convex molds), concave mold cavities, threaded cores, inserts, etc.

2. Casting system

It is a channel that guides the molten plastic from the turbocharger houcompressorsing molding machine nozzle to the closed mold cavity, usually composed of main channels, branch channels, gates, and cold wells.

3. Guide components

In order to ensure that the movable mold and the fixed mold can be accurately aligned when closed, the guide components are set to play a guiding and positioning role. It is composed of guide pins and guide sleeves. Some turbocharger compressor housing molds also have guide components on the ejector plate to ensure that the demoulding mechanism moves smoothly and reliably.

4. Demolding mechanism

The device that realizes the demoulding of plastic parts and casting systems has many structural forms. The most commonly used demoulding mechanisms include ejector pins, ejector tubes, ejector plates, and pneumatic ejectors. They are generally composed of ejector pins, reset rods, slingshots, ejector pin fixing plates, ejector plates (ejector rings), and ejector plate guide pins/guide sleeves.

5. Mold temperature adjustment system

In order to meet the turbocharger compressor housing mold temperature requirements of the plastic turbocharger housing molding process, a mold temperature adjustment system heating rod is required to adjust the mold temperature.

6. Exhaust system

In order to smoothly discharge the gas in the turbocharger housing mold cavity, exhaust grooves are often opened on the turbocharger housing mold parting surface and the matching place of the insert sleeve.

7. Other structural parts

Refers to the parts set to meet the requirements of the turbocharger compressor housing mold structure (such as: fixed plate, movable/fixed template, support column, support plate and connecting screws, etc.).

3/Composition and function of turbocharger housing mold

1. Upper fixed plate: an indispensable part for the machine table to open and close the mold and fix the mold and the front mold part of the turbocharger housing mold.

2. Stripper plate: fix the pull gate plate.

3. Magnet: control the turbocharger housing mold opening and closing through magnetism.

4. Square iron: cooperate with magnets to control the turbocharger housing mold opening and closing.

5. Male mold plate: fix the male mold core and mold core support plate.

6. Template support plate: fix the male mold plate and insert the heating rod at the same time.

7. Guide pin: fix the material belt.

8. Limiting column: limit the ejection height of the guide pin.

9. Mold angle: fixed function, and at the same time give the ejector plate enough height movement stroke

10. Upper ejector plate: fix the ejector.

11. Lower ejector plate: fix the upper ejector plate.

12. Lower fixed plate: fix the mold foot and garbage nail, and at the same time give the lower mold a basic fixation and use it to fix the mold on the machine table when opening and closing the turbocharger housing mold.

13. Garbage nail: limit the height, so that the lower ejector plate and the lower fixed plate can cooperate smoothly, and prevent debris from flowing into the two plates, so that the ejector and the guide pin are ejected unevenly.

14. Ejector column (K.O column): used for the machine to eject the ejector and guide pin.

15. Small ejector plate: fix the guide pin.

16. Small ejector plate: fix the guide pin.

17. Ejector: eject the material belt to separate the material belt from the turbocharger housing mold.

18. External pull rod: used to pull the cavity open and limit the cavity opening distance.

19. Heating rod: to heat the turbocharger houcompressorsing mold.

20. Mold core support plate: to fix the rear mold core and the rear mold insert.

21. Male mold core, fixed insert needle insert, mainly used for dry product turbocharger houcompressorsing molding.

22. Runner: part of turbocharger houcompressorsing molding.

23. Female mold core: fixed front mold insert, mainly used for product plastic turbocharger housing molding.

24. Female mold plate: fixed female mold core.

25. Small pull rod: fixed the mold opening stroke of the upper fixed plate and the stripper plate.

26. Mold core pad: fixed the female mold core and inserted the heating rod at the same time.

27. Pulling material fixing plate: fixed the pulling material needle to prevent the turbocharger housing mold from pushing the pulling material needle out during the turbocharger houcompressorsing molding process.

28. Nozzle: the main entrance for machine nozzle plastic turbocharger housing molding.

29. Pulling material plate: pull up the pulling material needle.

30. Pulling nozzle plate: fix the pulling needle.

31. Front mold insert: fix the runner plate and the mother mold core.

32. Back mold insert needle and sleeve: mainly used for product cup mouth turbocharger houcompressorsing molding.

33. Pulling needle: pull the nozzle.

4/Structural classification of injection molds

1. Classification by molding method:

(1) Injection mold: a mold used on an plastic turbocharger housing molding machine. Mainly used for molding thermoplastics, and a few types of thermosetting plastics are suitable for this plastic turbocharger housing molding.

(2) Compression mold: a mold that uses a compression process on a hydraulic press to mold plastic parts. It is mainly used to mold thermosetting plastics.

(3) Injection mold: a turbocharger housing mold that uses an injection process on a hydraulic press to mold plastic parts. It is suitable for plastic turbocharger housing molding thermosetting plastics.

2. Classification by the number of cavities:

It is a turbocharger houcompressorsing mold with only one cavity, and one plastic part is molded each time.

It is a turbocharger houcompressorsing mold with two or more cavities, which can mold multiple plastic parts.

3. Selection method of standard mold frame

1) Determine the combination form of the turbocharger housing mold frame according to the structure required for plastic part molding.

2) Determine the cavity wall thickness size.

3) Calculate the perimeter of the cavity template.

4) Select the standard perimeter size of the cavity template.

5) Determine the template thickness.

6) Select the turbocharger houcompressorsing mold frame.

7) Check the relationship between the mold frame and the turbocharger houcompressorsing molding machine.