KINGREAL UNIVERSAL IND., LTD

Phone

+86-137028558251/A Brief Introduction To The Car Door Mold

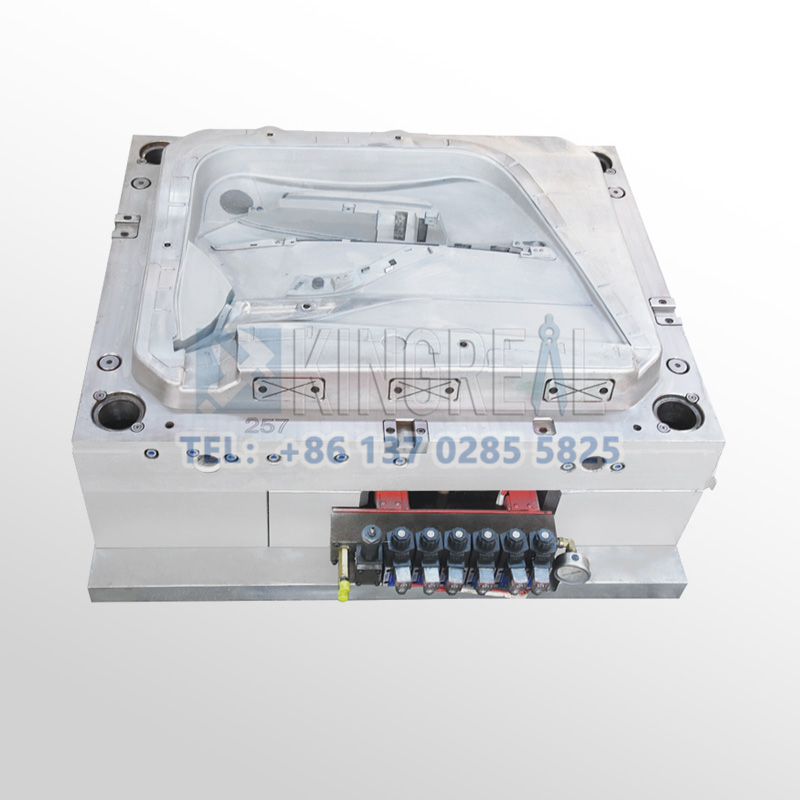

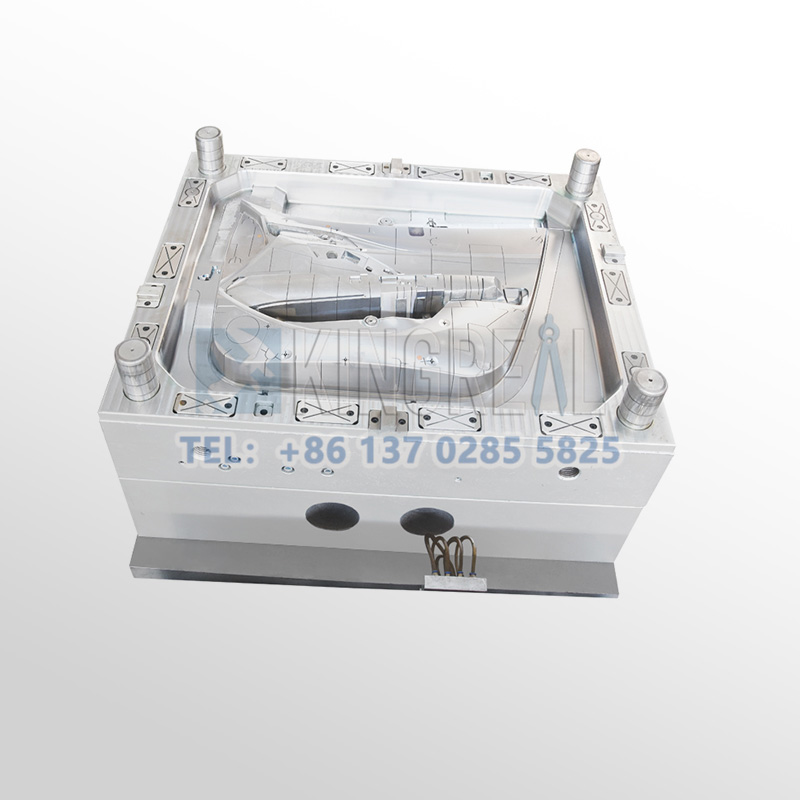

Automotive door panel molds are precision tools used to mold molten plastic into specific shapes. They are at the heart of the auto car interior door panel molding process, a manufacturing technology that has revolutionized the production of plastic products. The automotive door panel mold consists of two main parts: the cavity (which forms the outside of the plastic part) and the core (which forms the inside).

Auto car interior door panel molds vary greatly in complexity, from simple single-cavity designs to complex multi-cavity systems that can produce multiple parts at the same time. The precision of these car door molds directly affects the quality, consistency, and efficiency of the production process. Well-designed and well-maintained auto car interior door panel molds can produce thousands or even millions of identical parts with amazing precision.

As the core equipment for the production of plastic products, the service life of car door molds directly affects the production cost and production efficiency of enterprises. The automotive door panel mold life is restricted by many factors such as material properties, design structure, processing technology, use and maintenance, and needs to be systematically analyzed from the perspective of the entire life cycle.

The choice of auto car interior door panel mold material directly affects its wear resistance and fatigue strength. P20 pre-hardened steel is suitable for small and medium-sized batch production scenarios, with a hardness range of HRC28-32 and good machinability. H13 hot working die steel performs well in high temperature environments. After vacuum heat treatment, the surface hardness can reach HRC48-52, which is suitable for the production of high-temperature plastics such as PC and PMMA. The automotive door panel mold life of cemented carbide materials such as tungsten steel can reach millions of car door molds, but the processing cost increases by about 40%. In surface treatment technology, TD coating treatment can increase the automotive door panel mold surface hardness to above HV2800, and the resistance is increased by 3-5 times when the nitriding layer is 0.2-0.3mm deep.

2/Factors Affecting Car Door Mold Life

The life of auto car interior door panel molds is affected by a variety of complex factors:

1. Material selection: The material of the automotive door panel mold plays a key role in the durability of the car door mold. Compared with softer materials such as aluminum, hardened steel has better wear resistance. However, the choice of material must be balanced with factors such as cost, thermal conductivity and ease of processing.

2. Design complexity: Complex automotive door panel mold design is sometimes necessary for complex parts, but it will lead to increased wear and maintenance requirements. Features such as thin walls, deep ribs or complex cooling channels will create stress points, thereby shortening the life of the auto car interior door panel mold.

3. Environmental conditions: The production environment has a significant impact on car door mold life. Factors such as temperature fluctuations, humidity levels, and the presence of corrosive elements can accelerate wear and degradation. Maintaining a controlled environment is essential to maximizing automotive door panel mold life.

4. Frequency of use: The intensity and frequency of use directly affect the life of the auto car interior door panel mold. Continuous operation without adequate cooling time can cause thermal stress and premature wear. Implementing a proper production schedule to allow automotive door panel mold cooling and maintenance can extend its life.

5. Maintenance practices: Regular and thorough maintenance is perhaps the most critical factor in extending car door mold life. This includes daily cleaning, lubrication, and inspection for wear or damage. Proactive maintenance can prevent small problems from escalating into major problems that can shorten the life of the auto car interior door panel mold.

6. Machine quality: The condition and precision of the automotive door panel molding machine itself plays a major role in car door mold life. A well-maintained machine with precise clamping force and consistent operating parameters reduces excessive stress on the auto car interior door panel mold.

3/ Tips For Maintaining And Servicing Car Door Molds

(1) Preparation before mold operation

Before the automotive door panel mold is operated, the car door mold needs to be inspected and cleaned. Check the automotive door panel mold surface for damage or deformation to ensure that the mold works in normal condition. Clean the oil and dust on the car door mold surface to avoid affecting the use of the mold.

(2) Precautions when installing and removing the mold

When installing and removing the automotive door panel mold, it is necessary to keep it gently and stably installed to prevent damage to the mold. At the same time, pay attention to protecting the outer surface of the car door mold during the installation and removal of the mold to avoid damage.

(3) Mold heating and cooling control

During the automotive door panel molding process, the mold needs to be heated and cooled. During the heating process, the heating temperature and heating time should be controlled to avoid deformation or damage to the auto car interior door panel mold caused by excessive temperature. During the cooling process, the flow rate and temperature of the cooling water should be appropriate to avoid uneven cooling or frosting of the car door mold caused by excessive temperature.

(4) Regular inspection and maintenance of the mold

Regular inspection and maintenance of the auto car interior door panel mold is the key to ensuring the performance of the mold. First, it is necessary to regularly check the surface condition of the car door mold to see if there is any damage or deformation. Secondly, it is necessary to check the automotive door panel molding system and cooling system of the mold to ensure that the system is unobstructed. At the same time, the wear-resistant parts of the mold, such as nozzles and syringes, should be checked and replaced to avoid product quality problems caused by wear of wear-resistant parts.

(5) Precautions during car door molding During the injection molding process, the following points should be noted. First, the injection pressure and injection speed should be controlled to avoid damage to the mold due to excessive pressure and excessive speed. Second, the lubricant should be evenly applied to the surface of the automotive door panel mold to reduce the friction resistance during the auto car interior door panel molding process. In addition, the protective devices around the mold should be cleaned and replaced in time to avoid safety accidents caused by damage to the protective devices.

(6) Storage and maintenance of automotive door panel molds When the mold is not in use temporarily, it should be properly stored and maintained. First, the car door mold needs to be cleaned and coated with anti-rust lubricant to prevent rust on the mold surface. Second, a suitable storage location should be selected to avoid moisture and direct sunlight. In addition, for larger molds, a support frame should be used to support them to avoid deformation of the automotive door panel mold.