KINGREAL UNIVERSAL IND., LTD

Phone

+86-13702855825| 1 | Eliminating Impact of the Injection Molding Machine and Single Cavity Mold |

| 2 | Eliminating Influence of Raw Material Resins and Masterbatches |

| 3 | Eliminate Impact of Uneven Mixing of Color Masterbatch and Base Material |

| 4 | Reduce Impact of Barrel Temperature on Color Variation |

| 5 | Reduce Impact of Single Cavity Injection Molding Process Adjustments |

| 6 | Understand Impact of Barrel Temperature and Masterbatch Quantity on Product Color Variation |

Color control is crucial in the plastic injection molding industry, especially in single cavity injection molding. Product color variation is a common defect in single cavity injection molding plants, and batches of injection molding machines are often scrapped due to color differences in supporting parts. Numerous factors influence color variation, including the raw material resin, masterbatch, the blend of masterbatch and raw material, the molded product, the injection molding machine, and the single cavity mold. Due to this wide range of issues, color variation control technology is generally considered one of the most challenging techniques in single cavity molding. This article will focus on single cavity molds and single cavity injection molding, exploring in detail how to effectively control color variation and ensure production quality. |  |

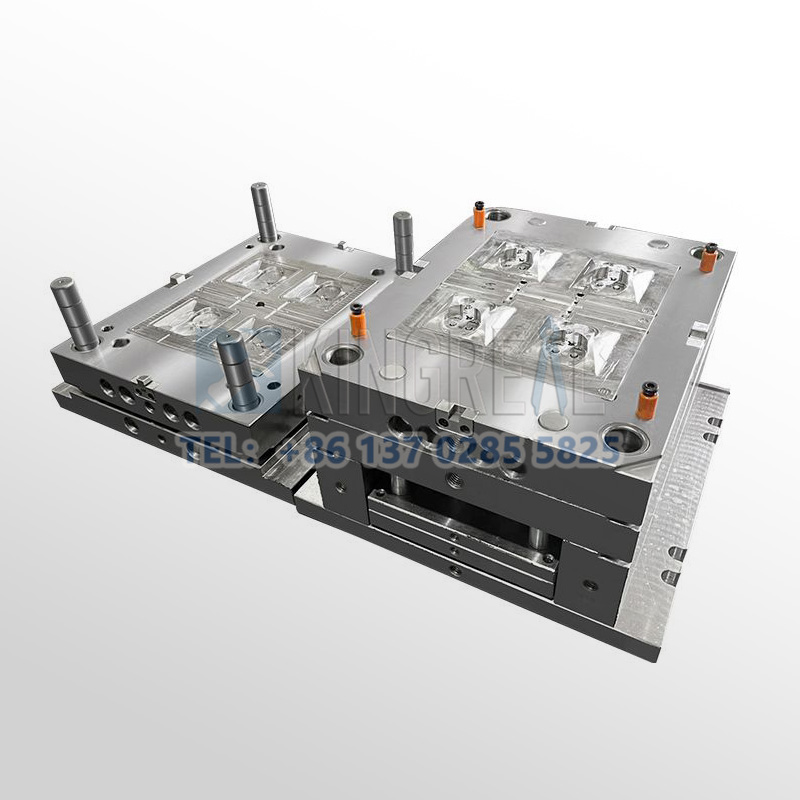

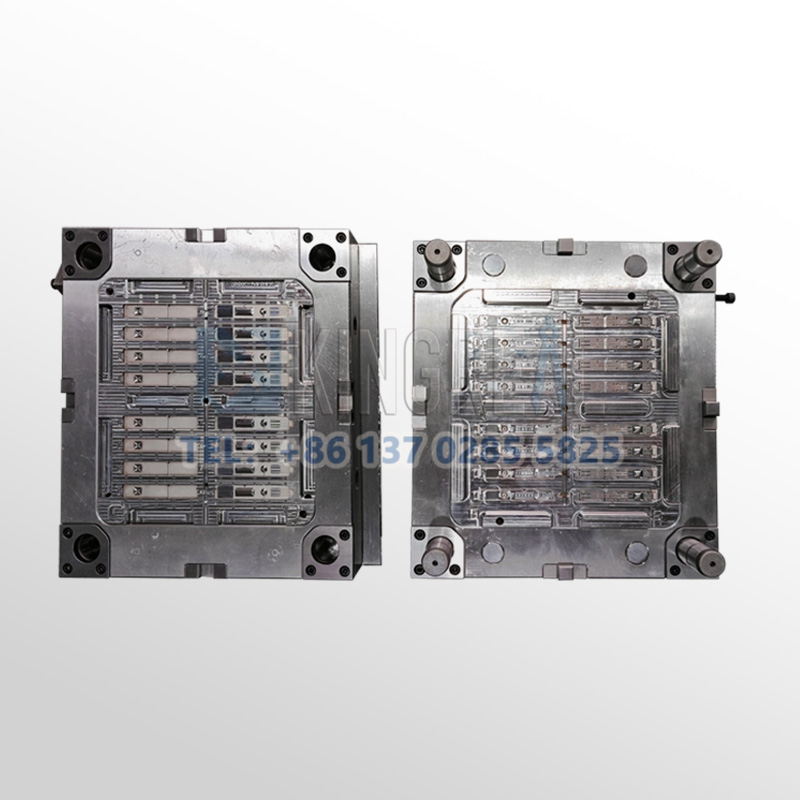

1. Eliminating Impact of the Injection Molding Machine and Single Cavity Mold

In the single cavity injection molding process, the selection and maintenance of the injection molding machine and single cavity mold are crucial. First, it is crucial to select an injection molding machine with a capacity comparable to the main product being molded. If the machine exhibits issues such as dead zones, it is best to replace the machine. The stability of the injection molding machine directly impacts product color consistency and yield. Color variations caused by issues like the gating system and venting grooves in single cavity molds can be corrected by repairing the corresponding mold components. Resolving issues with the injection molding machine and single cavity mold is a prerequisite for organizing production and reducing the complexity of subsequent issues.

2. Eliminating Influence of Raw Material Resins and Masterbatches

Controlling raw materials is key to completely resolving color variations. Especially when producing light-colored products, variations in the thermal stability of raw material resins can lead to color fluctuations. Since most single cavity injection molding manufacturers do not manufacture plastic masterbatches or masterbatches themselves, they must focus on production management and raw material inspection. This includes strengthening incoming raw material inspections and ensuring that masterbatches and masterbatches from the same manufacturer and brand are used throughout the production of the same product.

Prior to mass production, random color tests must be conducted to ensure consistency with the previous calibration. If there are slight color variations within the same batch of masterbatches, remix the masterbatches before use to minimize color variations caused by uneven mixing. Furthermore, the thermal stability of the raw material resin and masterbatches must be carefully inspected. Manufacturers are advised to replace materials with poor thermal stability.

3. Eliminate Impact of Uneven Mixing of Color Masterbatch and Base Material

The uniformity of mixing between color masterbatch and base material directly affects the color stability of products in single cavity injection molding. After mechanical mixing, when the material is drawn into the feed hopper, static electricity may cause the color masterbatch and base material to separate, leading to the masterbatch adhering to the walls of the hopper. This can result in variations in the amount of masterbatch during the injection cycle, causing color differences. To address this issue, manual stirring can be performed after the raw materials are drawn into the hopper.

Nowadays, many companies use feeders to add color masterbatch, which saves labor and greatly facilitates color difference control. However, due to improper use, the effectiveness of feeders is often unsatisfactory. At a fixed speed, the amount of masterbatch added by the feeder depends on the plastification time, which can fluctuate significantly. Therefore, the feeding time of the feeder should be set to be less than the minimum plastification time to ensure a constant feeding amount. Additionally, regular cleaning of the feeder is necessary to prevent material powder accumulation that could lead to inaccurate feeding and even feeder stoppage.

4. Reduce Impact of Barrel Temperature on Color Variation

During the single cavity injection molding process, color variation often occurs due to drastic changes in barrel temperature caused by damaged heater coils or out-of-control heating elements. This type of color variation is easy to detect and is often accompanied by uneven plasticization. Therefore, regular inspection of the heating system and prompt replacement of damaged or out-of-control heating elements are necessary to reduce the likelihood of color variation.

5. Reduce Impact of Single Cavity Injection Molding Process Adjustments

When adjusting single cavity injection molding process parameters for reasons other than color variation, the injection temperature, back pressure, injection cycle, and masterbatch dosage should be maintained as constant as possible. While making adjustments, observe the impact of these process parameter changes on color. If color variation is detected, adjust immediately. Avoid processes that induce strong shear, such as high injection speeds and high back pressures, to prevent localized overheating or thermal decomposition that can lead to color variation. Furthermore, strictly control the temperature of each barrel heating section, especially the nozzle and the heating elements immediately surrounding the nozzle, to ensure color consistency.

6. Understand Impact of Barrel Temperature and Masterbatch Quantity on Product Color Variation

Before adjusting color variations, it is essential to understand how product color changes with temperature and masterbatch quantity. Different masterbatches may exhibit different color variation patterns during the production process. Therefore, color trials are essential to determine these patterns. Only by understanding these patterns can color variations be adjusted quickly, especially when using new masterbatches.

Color control in single cavity injection molding is a complex and systematic process, involving the coordination and management of multiple links. By eliminating the influence of the injection molding machine and single cavity mold, controlling raw material stability, ensuring uniform mixing of masterbatches and base material, monitoring barrel temperature, and rationally adjusting single cavity molding process parameters, color variations can be effectively reduced and product quality consistency improved.

KRMOLD hopes that the control measures described in this article will provide valuable reference for practitioners in the single cavity molding industry and promote the further development of single cavity molding technology.