KINGREAL UNIVERSAL IND., LTD

Phone

+86-13702855825| 1 | What is Automotive Injection Molding? |

| 2 | How Automotive Injection Molding Works? |

| 3 | Advantages of Automotive Injection Molding |

| 4 | Material Selection for Automotive Injection Molding |

| 5 | Ready to try automotive injection molding? |

Car ownership is on an ongoing rising path with the growing popularity of vehicles. Not only do conventional production processes need expensive costs and protracted manufacturing times, they also fail to satisfy the increasing demand. Therefore, mass manufacture of plastic components has found a dependable and affordable approach in automotive injection molding.

Automotive parts injection molding enables accurate control of component size and performance in addition to fulfilling the automotive industry's demand for uniform, high-volume manufacture.

KRMOLD will offer a thorough introduction to automotive injection molding and serve as a reference for industry professionals. Contact KRMOLD for expert assistance if you have further personalization needs or technical questions concerning automotive parts injection molding.

1.What is Automotive Injection Molding?

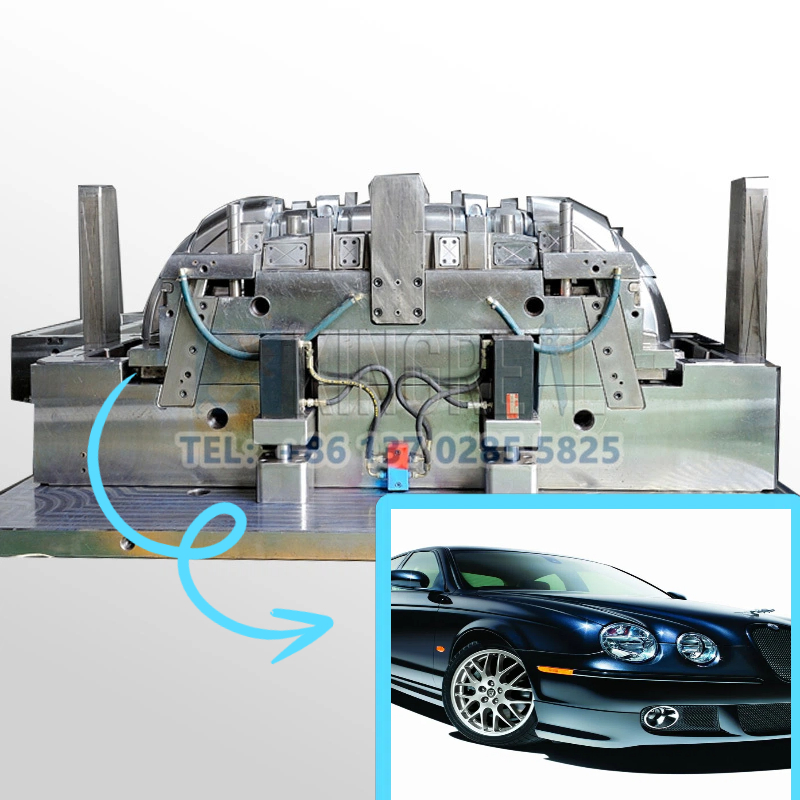

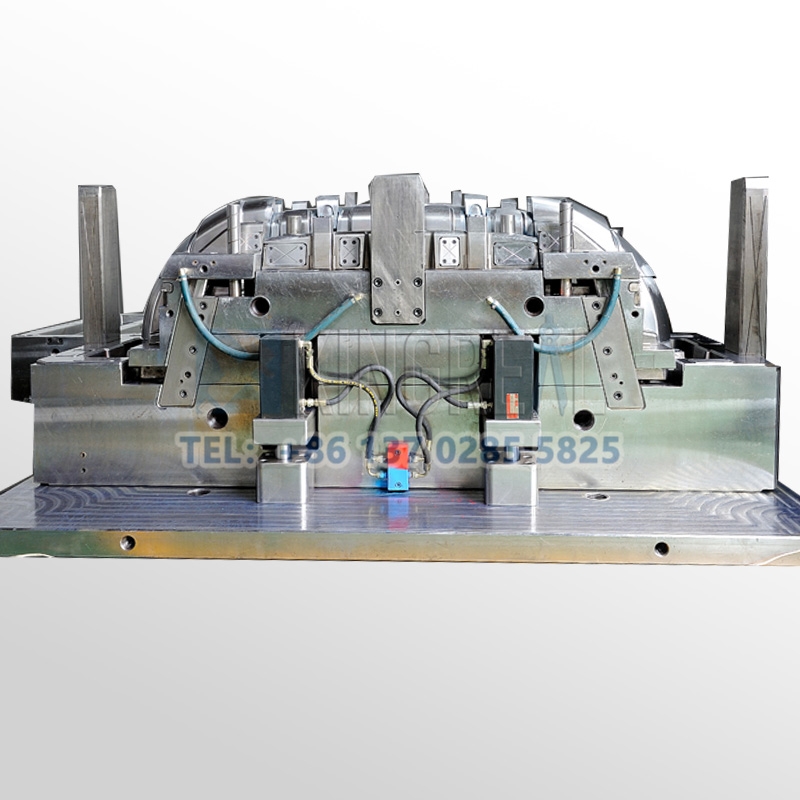

Automotive parts injection molding can create a range of automotive plastic components for the automotive industry. From external parts like bumpers, headlight casings, fenders, mirror housings, and grilles to everything made possible by contemporary car manufacturing via automotive injection molding Interior parts include the instrument panel, center console frame, door handles, seat adjustment buckles, and decorative interior panels. This automotive parts injection molding lets for flexible adjustment of process variables according on component functional requirements, thereby guaranteeing components satisfy the automotive industry's demanding guidelines for architectural strength, dimensional accuracy, and visual appeal.

2.How Automotive Injection Molding Works?

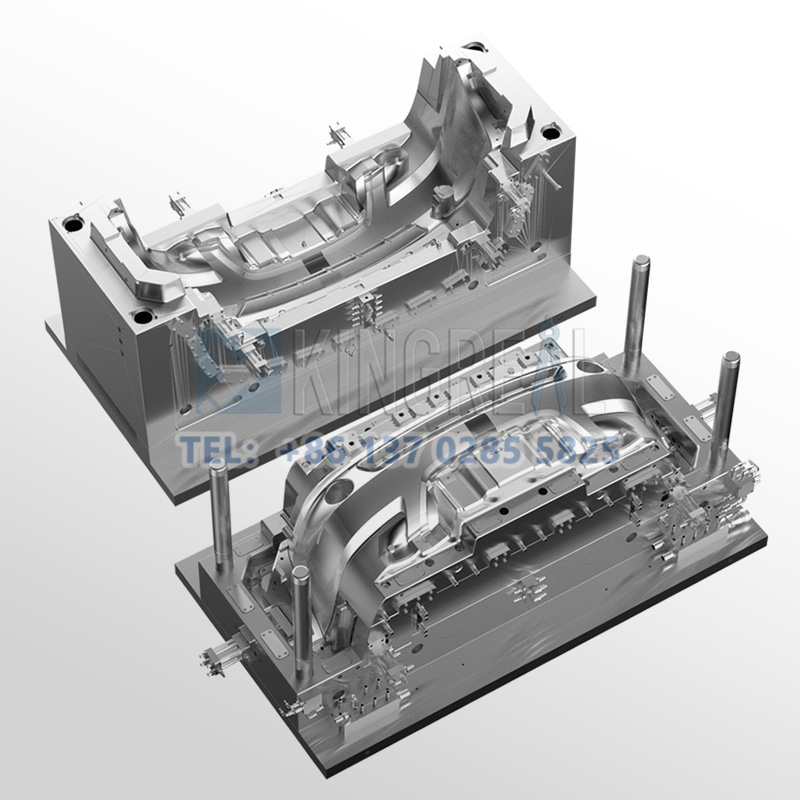

-Mold Design and Manufacturing: Based on automotive component drawings, technicians use CAD software to construct a 3D virtual model, defining dimensional tolerances, structural details, and assembly interfaces. Using CAM technology, these models are converted into machining data. CNC machines are then used to cut and polish mold steel (such as P20 or H13) to create the matching injection mold. The mold cavity surface roughness must be controlled within Ra 0.025-0.8μm to ensure component surface finish. During the injection molding stage, plastic pellets are placed in the injection molding machine's hopper and heated by a heating cylinder (180-300°C, depending on the material) to melt and form a fluidized plastic. The screw, driven hydraulically, advances at a speed of 10-50 mm/s, injecting the molten plastic into the mold cavity at a high pressure of 30-150 MPa, ensuring that the plastic fills the complex structural areas.

-Cooling and Curing: Circulating water (20-50°C) flows through the mold's built-in cooling channels to remove heat from the molten plastic, allowing it to solidify within 5-30 minutes (depending on part thickness). This cooling time must be precisely controlled to avoid defects such as sink marks and deformation.

-Demolding and Post-Processing: After the mold is opened, an ejector mechanism smoothly ejects the part, which is then collected manually or robotically. Acceptable parts are sent to the assembly line or undergo finishing processes such as deburring and drilling, completing the entire automotive injection molding process.

3.Advantages of Automotive Injection Molding

1)Precision and repeatability for automotive parts injection molding

Meeting the precise fitting requirements of automotive components (e.g., engine parts exactly fitting with metal parts), automotive injection molding can provide dimensional tolerances of ±0.01–±0.1mm. Moreover, molds made of high-strength mold steel can continuously produce 50,000–500,000 parts with a dimensional stability error of ≤0.02mm, ensuring consistent parts from batch to batch. batches and dimensional deviation avoidance of assembly issues.

2)Design adaptability for complex shapes for automotive injection molding

Through the "screw-forward" injection molding process, molten plastic under high pressure can fill the mold cavity with fine ribs (minimum thickness 0.5mm), hollow structures, and irregular curves, allowing complex parts to be formed in one go. For example, the internal air duct of an automotive engine intake manifold can be produced in one piece through automotive parts injection molding without requiring any splicing, ensuring air duct sealing and airflow stability.

3)Fast and efficient production capacity for automotive injection molding

A single injection molding machine completes a molding cycle in just 30 seconds to 5 minutes (e.g., 30 seconds/part for a small clip, 5 minutes/part for an instrument panel), supporting 24/7 continuous operation. Combined with automated production lines (such as robotic part removal and visual inspection), a single production line can achieve an average daily output of 5,000-20,000 parts, significantly improving the efficiency of automotive parts supply.

4)High surface finish for automotive parts injection molding

Fine polishing of the mold cavity offers a surface finish of Ra 0.04–0.4 μm, satisfying surface finish demands without extra painting. Additionally, mold surface treatment (sandblasting, etching) enables direct application of rough, matt, and textured coatings, therefore lowering labor and material costs.

4.Material Selection for Automotive Injection Molding

1) Polypropylene (PP) for automotive parts injection molding

Comprising over 30% of automotive plastics, it offers chemical resistance (to motor oil and antifreeze) and UV aging resistance, and is commonly used in bumpers, fenders, and cable insulation. Its density is only 0.9g/cm³, enabling lightweight components.

2) Polyvinyl Chloride (PVC) for automotive parts injection molding

Accounting for 16% of automotive plastic components, it comes in two forms: stiff (very stiff) and soft (flexible). Door panels are made of rigid PVC. Soft PVC is used for weather stripping and interior trim; it is flame-retardant (conforms with GB 8410 automotive interior combustion criteria). It is used for instrument panel frames also.

3) Polyurethane (PU) for automotive parts injection molding

Soft PU foam is used for seat padding (breathable and cushioning); rigid PU is used for sound insulation and heat shields, and engine heat shields; and flexible PU is used for oil seals and suspension bushings, offering wear resistance and strong sealing properties.

4) Polycarbonate (PC) for automotive parts injection molding

With a light transmittance of 90%, it is heat-resistant (long-term operating temperature of 120°C) and impact-resistant. It is used in headlight covers and sunroof glass (compounded with ABS). It weighs only half as much as glass, helping to reduce vehicle weight.

5)Polyamide (Nylon, PA) for automotive parts injection molding

Wear-resistant and oil-resistant, PA66 is commonly used in bushings and bearings; PA6 is used in fuel lines and oil filter housings and can withstand high engine temperatures (short-term heat resistance of 150°C).

6) Acrylonitrile Butadiene Styrene (ABS) for automotive injection molding

It has high rigidity and a bright surface. It is used in instrument panels and center console housings. It is also easy to electroplate (such as a metallic finish on steering wheels), enhancing the interior's quality.

7) Acrylic (PMMA) for automotive parts injection molding

With a light transmittance of 92% and strong weather resistance, it is used in headlight covers and in-vehicle display panels, replacing traditional glass. Its impact resistance is six times that of glass.

8) Polyethylene (PE) for automotive parts injection molding

With a density of 0.94g/cm³, it is impact-resistant and moisture-resistant. It's used in fuel tanks (HDPE) and water pipes (LDPE). It offers low cost and excellent processing fluidity.

5.Ready to try automotive injection molding?

With its great accuracy, efficiency, and wide material compatibility, automotive injection molding has become a central tool for the mass manufacture of automobile plastic components.

KRMOLD deeply engaged in the automotive injection molding field, provides comprehensive services from mold design and material selection to mass production, and offers free customized quotes. If you need to advance your automotive plastic parts mass production project, contact KRMOLD today to help you quickly implement your technology and increase production capacity.