KINGREAL UNIVERSAL IND., LTD

Phone

+86-13702855825| 1 | Applications of Electronic Housing Injection Molds |

| 2 | Key Elements of Precision Electronic Plastic Housing Injection Molding |

| 3 | Electronic Housing Injection Molding Parameter Settings |

| 4 | Electronic Housing Injection Molding Control |

Electronic housing injection molding is a key technology in the consumer electronics sector, a subcategory within the consumer electronics injection mold category. Mostly employed to create high-precision, premium electronic device casings, this process is Because of the strict standards for both appearance and usability of electronic devices, every factor in the electronic plastic housing injection molding process must be exactly managed to Make sure the finished product satisfies the greatest requirements for dimensional accuracy, shape precision, and surface quality of the sector.

1.Applications of Electronic Housing Injection Molds

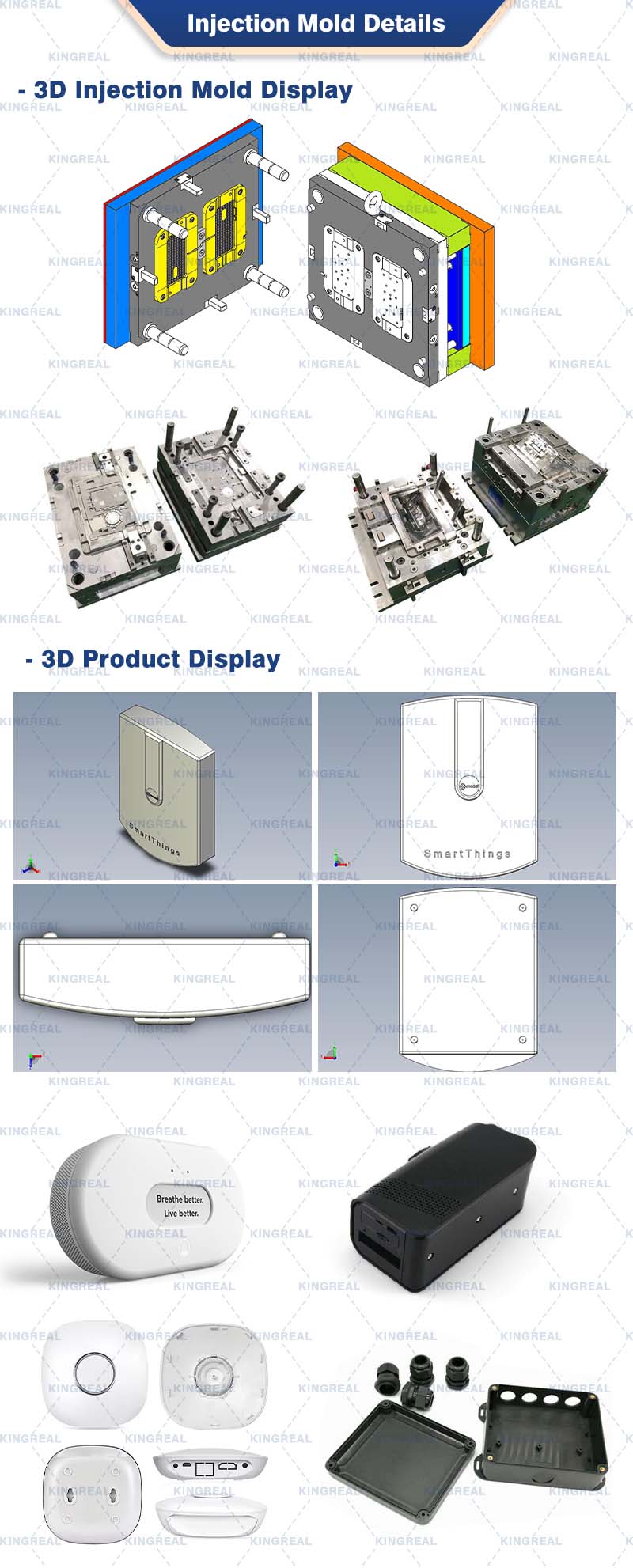

KRMOLD specializes in providing customized electronic housing injection molds. These electronic plastic housing injection molds are widely used in a variety of consumer electronics products, such as laptops, headphones, smart speakers, mobile phones, and tablets. Leveraging its extensive experience and technical expertise, KRMOLD is able to design electronic housing injection molds tailored to meet specific customer needs.

2.Key Elements of Precision Electronic Plastic Housing Injection Molding

-Electronic housing injection mold design and manufacturing

The rationality of electronic plastic housing injection mold design directly impacts the quality and production stability of electronic plastic housing injection molding. When designing the electronic plastic housing injection mold, consideration must be given to the product's demolding method and the layout of the cooling system. For example, for complex-shaped injection molded products, specialized ejection mechanisms such as sliders and beveled ejectors may be required to ensure smooth and damage-free removal.

During the housing design process, detailed optimization is crucial. For example, for housings with button holes and interface slots, the parting surface should be avoided in functional areas to prevent flash that could affect assembly quality. Furthermore, for thin-walled housings (thickness less than 1.5 mm), the gate size should be appropriately increased to avoid underfill, and conformal cooling should be employed to reduce warping caused by uneven cooling.

-Electronic housing injection mold material selection

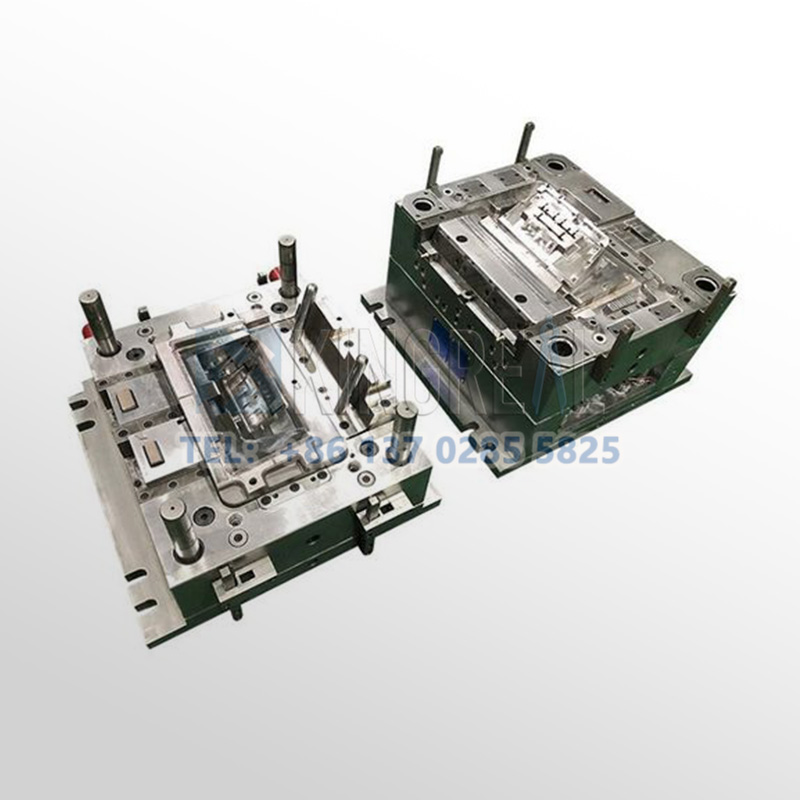

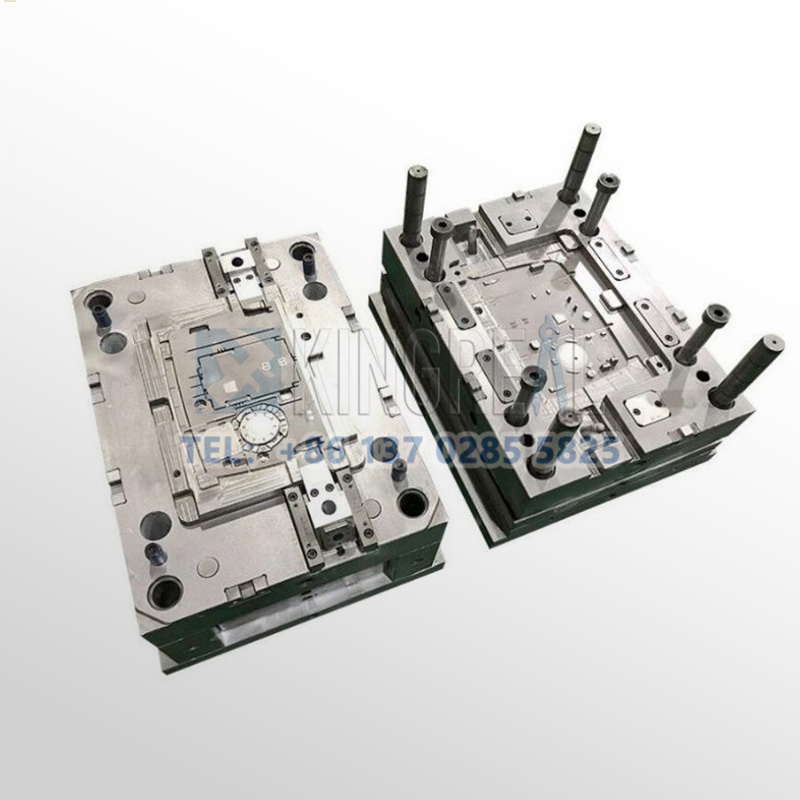

The material selected for the electronic plastic housing injection mold is crucial to its performance and service life. Electronic housing injection molds usually use high-quality mold steels like P20 and H13. With good thermal stability, corrosion resistance, and wear resistance, these steels help to maintain mold cavity accuracy throughout the long injection process.

For small to medium-sized production runs (less than 100,000 pieces), P20 pre-hardened steel can be used. This substance has great polishing characteristics and comparatively inexpensive processing costs. To improve surface hardness and lower cavity wear, H13 hot-work steel, nitrided, is advised for big production runs (over 500,000 units). Regarding regular maintenance, the mold cavity's residual material ought to be cleaned weekly, and the ejector pins should be checked monthly for wear so as to Avoid mold damage that might cause faults like dents or missing housing material.

-Processing precision control for electronic plastic housing injection molding

Mold processing precision is a crucial factor in ensuring the quality of electronic housing injection molding. During manufacturing, high-precision equipment including EDM devices and CNC machining centers must be used. Strict regulation of dimensions and accuracy is required; surface roughness must be obtained through careful programming and tool path planning.

3.Electronic Housing Injection Molding Parameter Settings

During the electronic plastic housing injection molding process, slight variations in molding parameters can lead to defects in batches of finished products, making precise optimization of these parameters crucial. First, regarding temperature control, the barrel temperature must match the melting point of the material being used. For example, the set temperature for polypropylene (PP) is 180-220°C, while for polycarbonate (PC), it should be 260-300°C. Too low a temperature can lead to uneven plasticization, while too high a temperature can cause material decomposition. Mold temperature settings also need to be adjusted based on appearance requirements. For high-gloss housings, the mold temperature should be between 80-100°C, while for standard housings, the temperature can be lowered to 50-60°C to shorten the cooling cycle.

Injection pressure and speed settings should be based on the principle of "full cavity filling without flash." Generally, injection pressure for thin-walled parts is set between 80-120 MPa, and for thick-walled parts, between 50-80 MPa. The injection speed should be controlled using a "staged control" strategy: a slow speed during the initial filling phase to prevent injection marks; a fast speed during the middle filling phase to minimize underfill; and a slow speed during the final phase to prevent flash. During the holding phase, the pressure should be set to 60%-80% of the injection pressure. The holding time should be adjusted based on the housing wall thickness. For example, a 2mm thick housing can hold for 3-5 seconds to effectively minimize surface shrinkage.

4.Electronic Housing Injection Molding Control

Real-time monitoring of injection pressure, holding time, and other data for every mold during the electronic plastic housing injection molding process by the machine's integrated parameter monitoring system. If parameter fluctuations exceed ±5%, the system automatically issues an alarm, allowing prompt investigation into issues such as raw material impurities or mold blockage. Additionally, hourly sampling inspections are conducted to monitor the filling status of the outer shell. The transparent cavity allows for clear observation of the melt flow path, enabling timely adjustments to the gate temperature and injection speed.

For cosmetic quality inspection, a high-intensity light inspection table is used to detect scratches and bubbles (a diameter exceeding 0.3 mm is considered unacceptable). For dimensional inspection, a 2D measuring instrument is used to inspect key dimensions (such as mounting hole spacing) with a tolerance of ±0.1 mm. For performance testing, each batch of samples undergoes a drop test (free drop from a height of 1.2 meters onto a concrete floor; no cracking of the outer shell is considered acceptable) and a sweat resistance test (immersion in artificial sweat for 48 hours, with no discoloration of the surface) to ensure the product meets actual usage requirements.