KINGREAL UNIVERSAL IND., LTD

Phone

+86-13702855825General Contents:

1. Introduction to Washing Machine Plastic Injection Mold

2. Washing Machine Plastic Injection Mold Repair

3. Washing Machine Plastic Injection Mold Maintenance

4. Safety Issues in Washing Machine Plastic Mould Repair and Maintenance

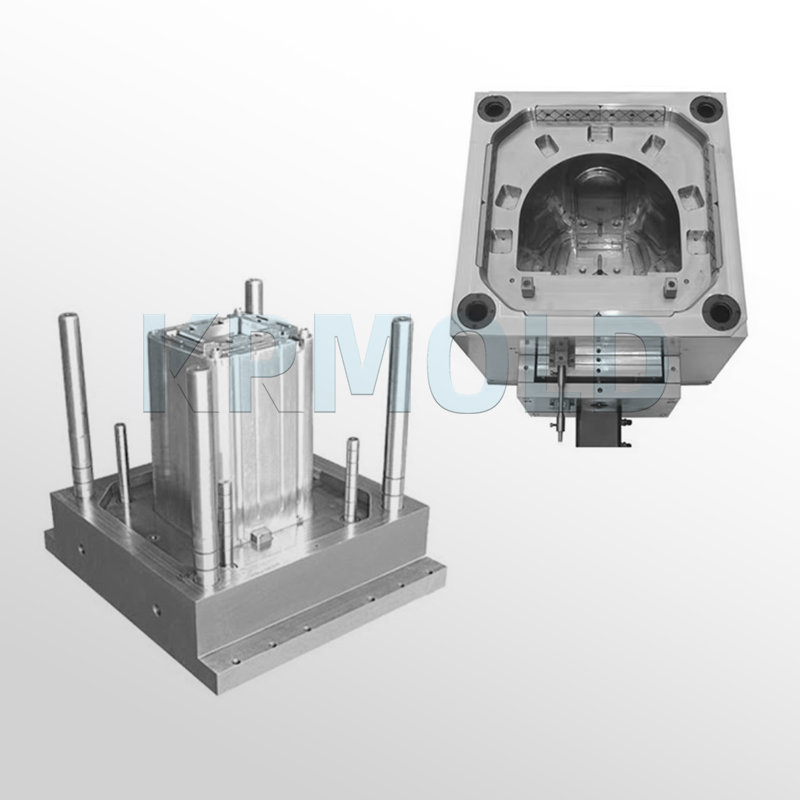

As a crucial production tool for washing machines, washing machine plastic mould are responsible for manufacturing the internal plastic parts. Once molded through the injection molding process, these parts not only have complete structures and precise dimensions but also enable large-scale production. The injection molding process involves injecting heated and molten plastic under high pressure into the mold cavity, where it cools and solidifies to obtain the desired plastic part. Therefore, proper maintenance and upkeep of washing machine plastic injection molds are particularly important. Today, KRMOLD will focus on the key points of maintenance and upkeep for washing machine injection mould.

1. Introduction to Washing Machine Plastic Injection Mold

1.1 Application of Washing Machine Plastic Mould

Washing machine plastic injection molds are widely used for thermoplastic plastics such as ABS, PP, PC, and POM, while thermosetting plastics such as phenolic and epoxy plastics use rubber molds.

1.2 Classification of Washing Machine Plastic Injection Molds

Based on structure, they can be divided into two-plate molds and three-plate molds; based on gate design, they can be divided into large gate, single-point gate, and hot-point gate.

1.3 Washing Machine Plastic Injection Mould Structure

The structure of a washing machine plastic mould mainly includes the following parts:

Molding Components: These are the front and rear mold cores, which are in direct contact with the product.

Gating System: Molten plastic flows into the cavity through the main runner, branch runners, and gate.

Guiding System: Ensures the relative position of the front and rear molds when they are closed, typically including guide pillars and guide bushings.

Ejection Structure: Uses ejector pins, ejector plates, etc., to remove the plastic part from the washing machine plastic injection mold.

Temperature Control System: Regulates the mold temperature by adding cooling channels to meet the injection molding process requirements.

Side Parting and Core Pulling: Handles structures that do not conform to the ejection direction, using slide blocks or angled ejectors.

Ventilation Structure: Located at the parting surface, used to expel air from the cavity and gases generated during the molding process; common forms include venting grooves.

2. Washing Machine Plastic Injection Mold Repair

During use, washing machine plastic mould inevitably experience wear or damage. Timely mold repair is crucial to prevent defective products.

2.1 Mold Repair Plan Inspection and Development

When washing machine plastic injection mold damage is discovered, first inspect the extent of the damage, then refer to the condition of a normal washing machine plastic mould to develop a corresponding repair plan.

2.2 Mold Repair Principles

The repair process must adhere to the principle of "not affecting the structure and dimensions of the plastic part," especially when making dimensional adjustments. Accurate dimensional data must be recorded before proceeding to the next step.

2.3 Assembly and Disassembly Precautions

Marking: When disassembling parts, carefully read the markings on the washing machine plastic mould to ensure accurate reassembly.

Mistake-proof Design: For parts prone to misassembly, establish structures to prevent errors.

Neat Placement: Disassembled parts must be neatly placed to prevent confusion.

Protective Measures: For precision parts such as cores and cavities, protective measures must be taken to avoid damage.

2.4 Precautions for Repairing Textured Surfaces

When repairing textured surfaces, the following points require special attention:

Mold Protection: Protecting the textured surface before repair is crucial to avoid smoothing.

Welding Process: Use welding rods consistent with the mold core material during welding and perform tempering treatment.

Texturing Notes: When texturing, ensure the texturing material is consistent with the original material and provide a sample for confirmation.

3. Washing Machine Plastic Injection Mold Maintenance

The frequency and quality of daily maintenance directly affect the service life of the washing machine plastic mould. Regular maintenance can effectively reduce the frequency of subsequent repairs.

3.1 Importance of Maintenance

-Maintaining Normal Operation: Reduce unnecessary wear on moving parts.

-Extending Service Life: Ensure the washing machine plastic injection mold is used in optimal condition.

-Reducing Oil Stains: Keep the production environment clean.

3.2 Maintenance Categories

-Daily Maintenance: Clean and lubricate commonly used parts and washing machine plastic mould surfaces.

-Regular Maintenance: Regularly check washing machine plastic injection mold venting channels and repair worn areas.

-Appearance Maintenance: Apply paint and rust-preventive oil to prevent rust.

3.3 Maintenance Content

●Daily Maintenance:

-Lubricate all moving parts.

-Clean the washing machine plastic mould surface.

-Ensure unobstructed water channels.

●Regular Maintenance:

-Same as daily maintenance items.

-Clean the venting channels thoroughly, ensuring no blind spots.

-Treate damaged and worn areas.

●Appearance Maintenance:

-Regularly paint the exterior of the washing machine plastic injection mold to prevent oxidation.

-Apply anti-rust oil when removing the washing machine plastic mould.

-Store in a sealed container to prevent dust intrusion.

3.4 Maintenance Precautions

Lubricate moving parts daily to ensure normal operation.

Cleaning the washing machine plastic injection mold surface is crucial; never affix labels to the P/L surface.

Immediately repair any abnormalities.

4. Safety Issues in Washing Machine Plastic Mould Repair and Maintenance

Safety is paramount in any operation, especially in the repair and maintenance of washing machine plastic injection molds:

-Lifting Ring Inspection: Ensure lifting rings are intact before use.

-Protective Equipment: Wear safety glasses while operating the equipment.

-Welding Safety: Wear protective clothing and goggles when welding.

-Operating Procedures: Do not work at the bottom of the washing machine plastic mould; ensure the injection molding machine is stopped.

During the operation of the washing machine plastic injection mold, it is imperative to follow safety regulations, regularly check the washing machine plastic mould' condition, and perform timely maintenance to extend its service life. Always adhere to the principle of "maintenance before repair" to continuously improve the washing machine plastic injection mold's working efficiency and safety.