KINGREAL UNIVERSAL IND., LTD

Phone

+86-13702855825General Contents

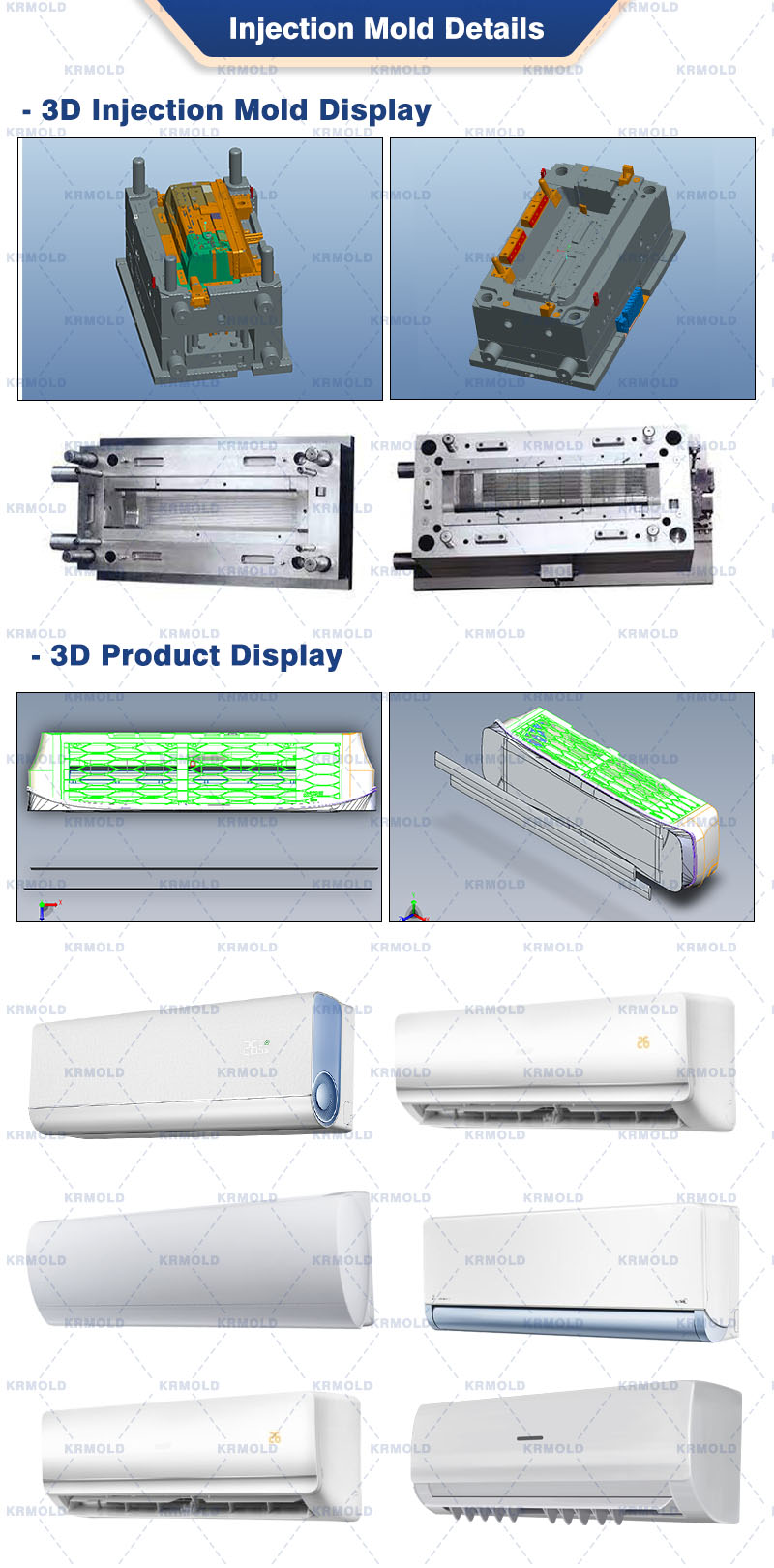

1/Introduction to Air Conditioning Panel Injection Mold

2/Design Process of Air Conditioning Panel Injection Mold

3/Key Design Considerations for Air Conditioning Panel Injection Mold

Air conditioning panel injection molds are specifically designed for producing high-volume, precision-engineered plastic air conditioner panels, widely used in air conditioner installation. Plastic air conditioner shell mould design is crucial, as it directly determines the air conditioning panel injection mold's lifespan and the quality of the plastic products. This article by KRMOLD will discuss the design process and key aspects of plastic air conditioner shell mould in detail, aiming to provide practical guidance for professionals in related industries.

1/Introduction to Air Conditioning Panel Injection Mold

Plastic air conditioner shell mould are specifically designed for manufacturing plastic components for air conditioners. Typically, these air conditioning panel injection molds are made of high-quality materials such as steel or aluminum and are precisely designed to ensure consistency in the dimensions, shape, and quality of the plastic parts. The plastic air conditioner shell mould manufacturing process for air conditioner plastic parts mainly involves the following steps: -Design Stage: Creating the part design using Computer-Aided Design software. -Rapid Prototyping: Creating prototypes using rapid prototyping technologies (such as 3D printing or CNC machining). -Plastic air conditioner shell mould Making: After the prototype is approved, the actual air conditioning panel injection mold is made using metal injection molding or investment casting. After the plastic air conditioner shell mould is completed, it is placed into the injection molding machine. The machine heats plastic material and injects it into the mold cavity, then cools and solidifies it into the desired shape. Finally, the finished part is removed from the air conditioning panel injection mold and undergoes quality inspection; if it passes inspection, it is sent to the customer. |  |

2/Design Process of Air Conditioning Panel Injection Mold

Plastic air conditioner shell mould design is a complex and lengthy process, mainly including the following steps:

2.1 3D modeling for air conditioning panel injection mold

To ensure design accuracy, a 3D model of the air conditioner panel is first required. The outer surface of this plastic product must be glossy and free of defects such as cold marks or clouding. Furthermore, considering the large length, width, and height of the plastic part and its complex shape, special attention is needed during the design process.

2.2 Plastic part analysis for plastic air conditioner shell mould

After completing the 3D model, the next step is to analyze the plastic part. At this stage, the key point is to determine the parting surface of the plastic air conditioner shell mould. The selection of the parting surface directly affects the ease of demolding and the structural complexity of the air conditioning panel injection mold. Therefore, the simplicity of the mold structure and the machining accuracy of the plastic part should be comprehensively considered during the design.

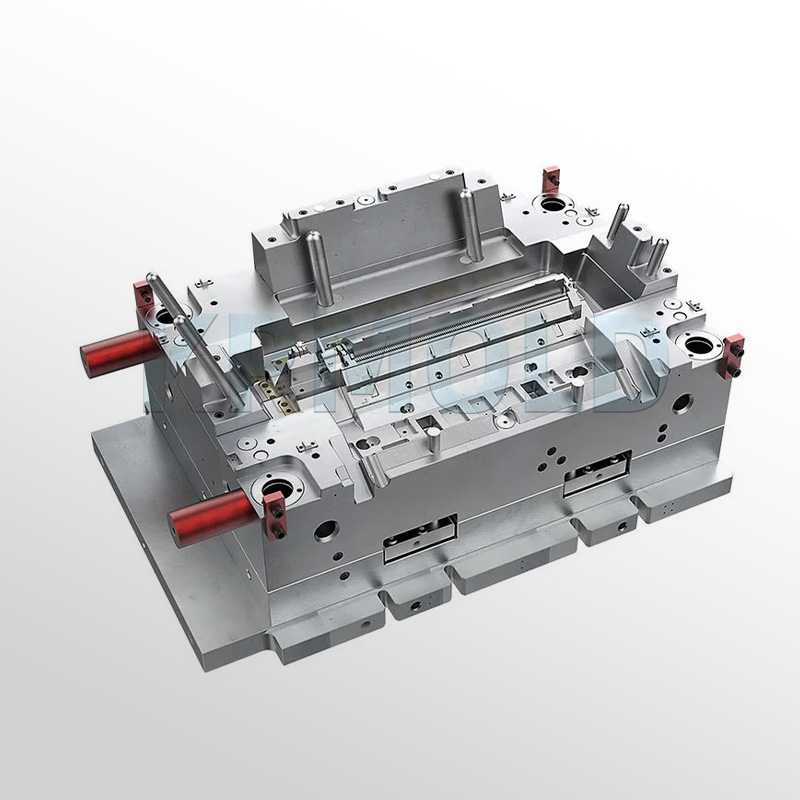

2.3 Parting surface design for plastic air conditioner shell mould

When selecting the parting surface, it is necessary to ensure smooth demolding, simplify the air conditioning panel injection mold structure, and guarantee the surface accuracy of the plastic part. The mold cavity should be able to accommodate the outer surface of the plastic part. The parting line needs to be designed in areas where molding is difficult, such as the grille at the top of the plastic part, to utilize the gap between the moving mold block and the parting line for venting.

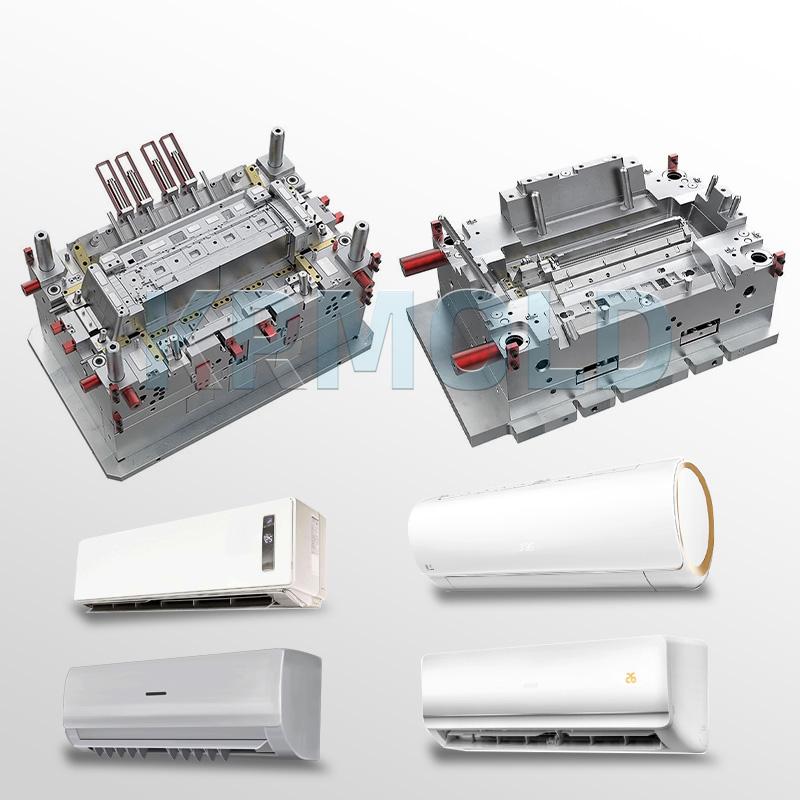

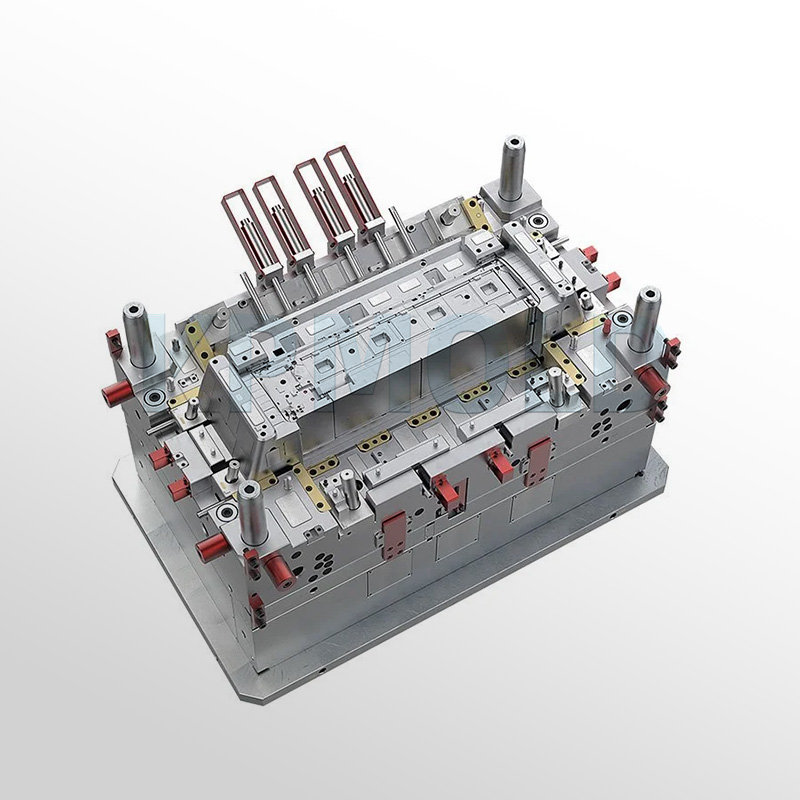

2.4. Core and cavity design for plastic air conditioner shell mould

Due to the large volume of the mold, designing the core and cavity as a single unit would result in material waste and may lead to reduced precision and processing deformation. Therefore, the design of air conditioner panel injection molds typically adopts an interlocking structure, which can effectively remove gas from the cavity.

2.5 Core pulling mechanism design for air conditioning panel injection mold

A core pulling mechanism is essential for air conditioning panel injection molds. The design of the side core pull should be integrated with the parting line, making it part of the moving mold. During mold opening, the plastic part is tightly attached to the core and moves together with the moving mold part. The side core pull slider also moves accordingly to complete the core pulling process.

2.6 Gating system design for air conditioning panel injection mold

The gating system is the general term for the flow path of the molten plastic from the nozzle into the mold cavity. A well-designed gating system can ensure the smooth flow of the melt. Therefore, special attention should be paid to the form and dimensions of the gating system during design to ensure smooth injection and pressure holding.

2.7 Cooling system design for air conditioning panel injection mold

Since high temperatures are generated at the center of the plastic air conditioner shell mould during injection molding, the cooling system design should ensure uniform temperature distribution within the air conditioning panel injection mold and meet the requirements for the economical number of cycles during molding. The cooling of the fixed mold section should include a cooling circuit in the cavity fixing plate that resembles the shape of the plastic part.

3/Key Design Considerations for Air Conditioning Panel Injection Mold

Several key considerations deserve special attention when designing plastic air conditioner shell mould:

3.1 Material selection for air conditioning panel injection mold

The mold material directly affects the plastic air conditioner shell mould' lifespan and the quality of the molded product. Generally, the material selection for air conditioning panel injection molds should prioritize high-hardness, wear-resistant materials, such as high-quality steel or aluminum alloys, to withstand the high temperatures and pressures during injection molding.

3.2 Precise machining process for plastic air conditioner shell mould

The machining precision of the air conditioning panel injection mold determines the quality of the plastic product. Therefore, high-precision CNC machining equipment should be used for air conditioning panel injection mold manufacturing. Furthermore, post-processing polishing is also an important step to ensure a smooth, flawless product surface.

3.3 A sound venting system for air conditioning panel injection mold

A good venting system is crucial for the proper operation of the plastic air conditioner shell mould. During plastic injection, gases may be generated inside the air conditioning panel injection mold. If these gases are not removed in time, they will affect the quality of the finished product and lead to injection failure. Therefore, the layout of the venting channels must be fully considered in the design.

3.4 A balance between efficiency and cost

In plastic air conditioner shell mould design, efforts should be made to improve production efficiency and reduce costs while ensuring quality. For example, this can be achieved by simplifying the air conditioning panel injection mold structure and selecting appropriate processing technology and materials to achieve the best balance between cost and performance.