Are you curious about how plastic products are manufactured using plastic injection molds? Are you curious about how KRMOLD guarantees plastic injection mold quality? Do you have doubts about KRMOLD plastic-injection-mold-making capabilities? Do you want to know what tests the plastic injection molds undergo before being shipped to you? If you have any of these questions, this page can answer them for you!

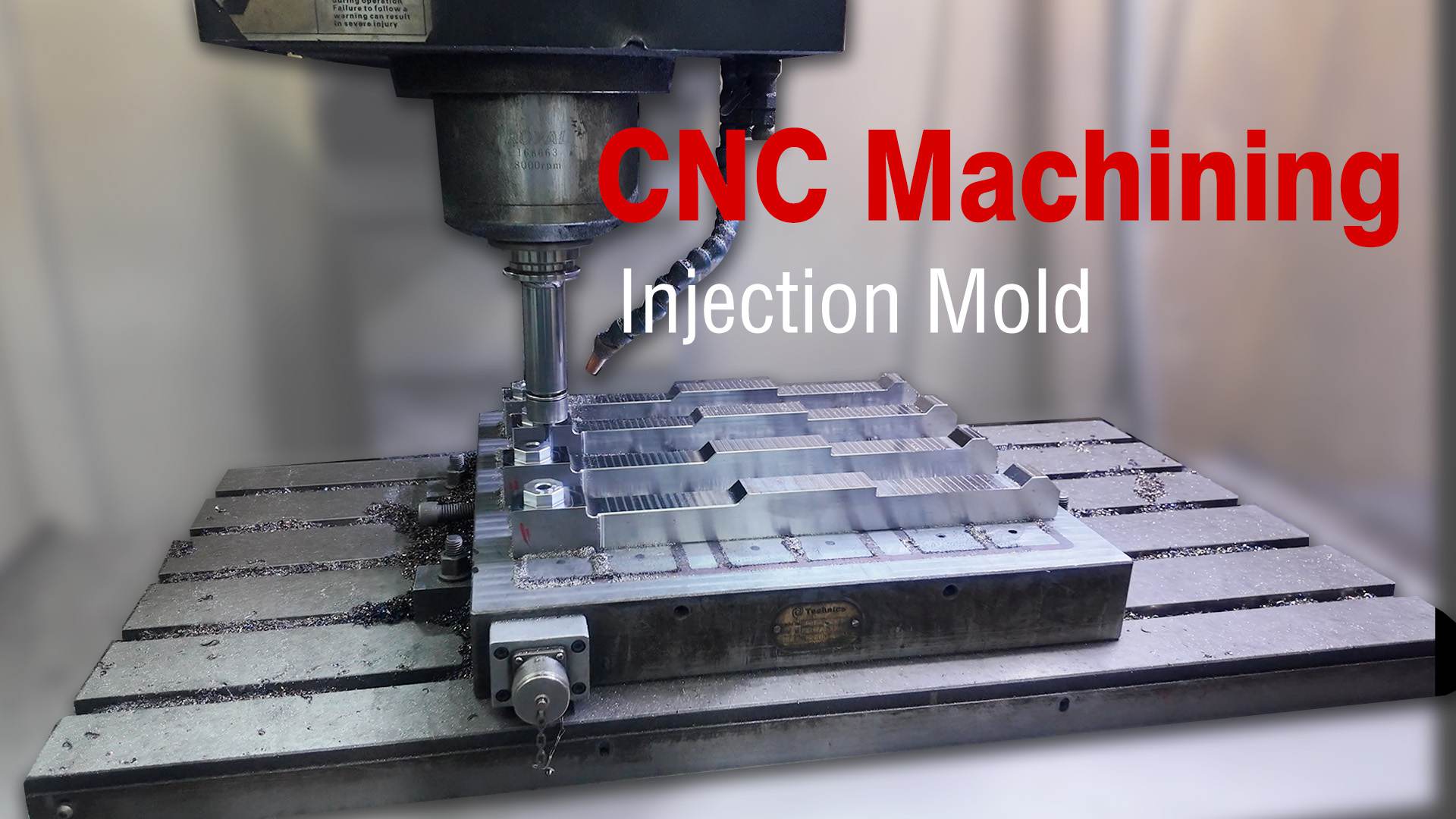

Here, you will learn about KRMOLD rigorous process for comprehensive plastic injection mold inspection. KRMOLD ensures that mold quality meets customers' high standards through multiple inspection methods, including dimensional inspection, shape inspection, material inspection, surface quality inspection, and precision inspection. First, KRMOLD conducts strict dimensional inspections on the completed plastic injection molds. KRMOLD engineers use high-precision measuring instruments to measure every detail of the plastic injection mold. This process aims to ensure that every dimension of the plastic injection mold accurately meets design requirements. Next, the plastic injection mold enters the shape inspection stage. At this stage, KRMOLD ensures that the plastic injection mold's geometry conforms to the design. Furthermore, KRMOLD places great emphasis on material inspection. KRMOLD uses mold steel that undergoes rigorous compositional analysis and physical property testing to ensure excellent durability, wear resistance, and pressure resistance.

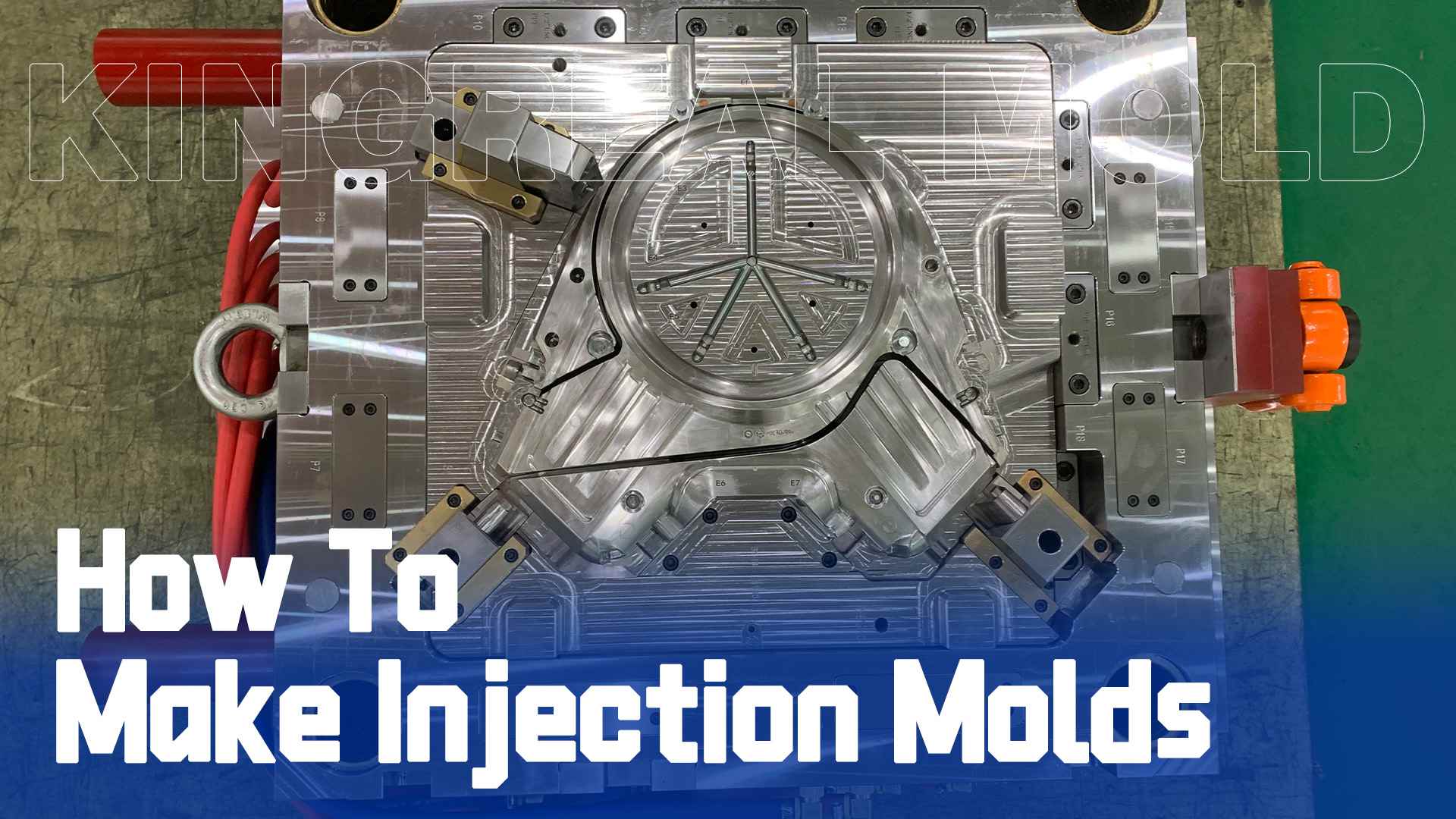

Here, you will witness KRMOLD strict control over plastic injection mold surface quality. Mold surface treatment directly affects the appearance and feel of plastic products. KRMOLD employs advanced surface treatment technology to ensure a smooth, flawless mold surface. This not only facilitates smooth demolding of plastic parts but also improves the visual appeal and performance of the finished product. Furthermore, KRMOLD conducts a trial molding process, which is the final verification of plastic injection mold quality. During this process, KRMOLD injects actual plastic material and observes the plastic injection mold's actual performance through multiple trial moldings. Samples produced here undergo rigorous quality testing, including dimensions, appearance, and functionality. This ensures that the final product not only meets design requirements but also demonstrates high performance and aesthetic appeal in actual use.

Here, you'll also see KRMOLD comprehensive testing of different types of plastic injection molds, such as automotive trim strip injection mold, washing machine plastic injection mold, plastic pallet injection mold, and waste bin injection mold. These plastic injection molds are meticulously designed and manufactured to deliver superior performance in their respective applications.

If you'd like to learn more about the plastic injection mold manufacturing process or watch related videos, please feel free to contact KRMOLD. KRMOLD continuously updates you with updates on our factory staff inspecting and manufacturing plastic injection molds, showcasing KRMOLD professionalism and rigor.