KINGREAL UNIVERSAL IND., LTD

Phone

+86-13702855825| 1 | Key Points in Plastic Bottle Cap Injection Mould Design |

| 2 | Process of Bottle Cap Plastic Injection Molding |

| 3 | Bottle Cap plastic Injection Mold Maintenance |

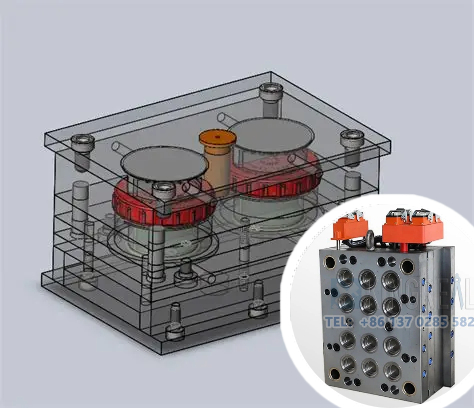

Designed expressly for mass manufacturing of plastic bottle lids, plastic bottle cap injection mould are crucial instruments. Extreme accuracy and dependability are needed in bottle cap plastic injection mold design to guarantee that the caps' dimensions, threads, and sealing qualities satisfy all requirements. Usually constructed of wear-resistant, high-hardness steel, these bottle cap plastic injection molds enable sophisticated thread forms and small injection passages to guarantee exact shaping and quick manufacture. Moreover, hot runner systems included in many bottle cap plastic injection molds help to minimize material waste and enable quick cycle times, hence boosting production efficiency. Precise cooling systems are also essential to ensure quality while reducing molding time.

KRMOLD offers a variety of plastic bottle cap injection mould, including screw cap injection molds, flip cap injection molds, 5-gallon cap injection molds, water bottle cap injection molds, and shampoo bottle cap injection molds. KRMOLD provides comprehensive services, from bottle cap plastic injection mold design and mold flow analysis to plastic bottle cap injection mould manufacturing, testing, and packaging. This article will provide a detailed introduction to bottle cap plastic injection molds to help readers better understand their importance and applications in production.

1.Key Points in Plastic Bottle Cap Injection Mould Design

1)Designing the product's appearance

One must remember that plastic molding techniques enable complicated shapes before creating a bottle cap plastic injection mold. This implies that the cap design of the bottle can be updated with details as necessary. Branding elements are, for instance, also crucial component of the design; several businesses want to show their brand logos on their bottle lids to boost their market competitiveness. To guarantee a tight seal and simplicity of usage, the bottle cap's internal and external thread systems should complement the external threads of the bottle body.

2)Plastic bottle cap injection mould processing

KRMOLD engineers will prepare a bottle cap plastic injection mold based on the bottle cap design drawings provided by the customer. The plastic bottle cap injection mould will contain the cavity used to shape the plastic raw material into the desired bottle cap shape. Depending on the complexity of the bottle cap design, the plastic bottle cap injection mould processing of the bottle cap could be quite lengthy. Complex designs call for more processing steps and high-precision equipment to guarantee every detail is flawlessly reproduced.

3)Plastic bottle cap injection mould material selection

Choosing the right bottle cap plastic injection mold material is crucial for achieving optimal cycle performance. Different mold materials offer different cycle efficiencies. For example, steel molds are more durable than aluminum molds. Although steel molds are more expensive, their long-term advantages are not negligible. During this process, KRMOLD engineers will consider the customer's injection molding costs and production goals to determine the optimal mold material selection.

4)Reusability of bottle cap plastic injection mold

For one-off projects, it's worth considering using relatively inexpensive mold materials with shorter lifecycles. However, for continuous production projects, using more expensive mold materials will benefit long-term development and reduce costs. Reusable plastic bottle cap injection mould maintain high production efficiency over time and reduce downtime due to bottle cap plastic injection mold wear.

2. Process of Bottle Cap Plastic Injection Molding

1) Clamping the bottle cap plastic injection mold

Link the feed system to the bottle cap plastic injection mold by clamp the plastic bottle cap injection mould based on the tonnage needs of the machine. Following tonnage restrictions guarantees the plastic bottle cap injection mould keeps a steady posture during manufacturing, hence avoiding displacement or deformation during the injection molding process. process that could influence the quality of the bottle top.

2) Feeding the plastic material

The plastic material must be fed into the bottle cap plastic injection mold before the injection molding process starts so guaranteeing readiness for production. Pre-dried plastic pellets are usually fed into the plastic bottle cap injection mould via the feed port. High-quality bottle lids depend on making sure the material is dry and pure.

3) Using an extrusion mechanism

Extrusion is used when producing plastic bottle caps and is the best choice for producing tubular products. The extrusion mechanism creates the optimally designed plastic bottle cap, incorporating the internal thread system. The extrusion mechanism ensures that the plastic material is evenly heated and smoothly injected into the bottle cap plastic injection mold.

4) Cooling process of injection molded plastic

Before it may be ejected from the plastic bottle cap injection mould, the bottle cap has to cool following injection moulding. The cooling time relies on several variables including the kind of plastic material used, bottle cap plastic injection molding, and temperature outside. A well-designed cooling system is crucial to effectively reduce the temperature of the bottle cap and ensure that it maintains the desired shape and dimensions.

5) Ejecting the cap from the plastic bottle cap injection mould

After cooling is complete, the molded bottle cap can be removed from the mold cavity. The bottle cap plastic injection mold is capable of handling thousands of production cycles, so this process can be repeated as needed. After removal, simple post-processing, such as trimming or cleaning, may be required to ensure the quality of the finished product.

3. Bottle Cap plastic Injection Mold Maintenance

Regular maintenance is essential to keep your plastic bottle cap injection mould in good working condition. Here are some key maintenance recommendations:

-Regular inspections for bottle cap plastic injection mold: Perform a comprehensive plastic bottle cap injection mould inspection regularly to ensure that all components are functioning properly and address any issues promptly.

-Bottle cap plastic injection mold cleaning: After each production run, the plastic bottle cap injection mould are cleaned to remove residual plastic and impurities to prevent them from affecting the next run.

-Lubrication for bottle cap plastic injection mold: Regularly lubricate moving parts to ensure smooth plastic bottle cap injection mould operation.

-Temperature monitoring for bottle cap plastic injection mold: Monitor plastic bottle cap injection mould temperature to ensure it remains within a reasonable range during production to prevent deformation caused by overheating.

-Replace worn parts for bottle cap plastic injection mold: Replace severely worn parts promptly to prevent impacting overall mold performance.