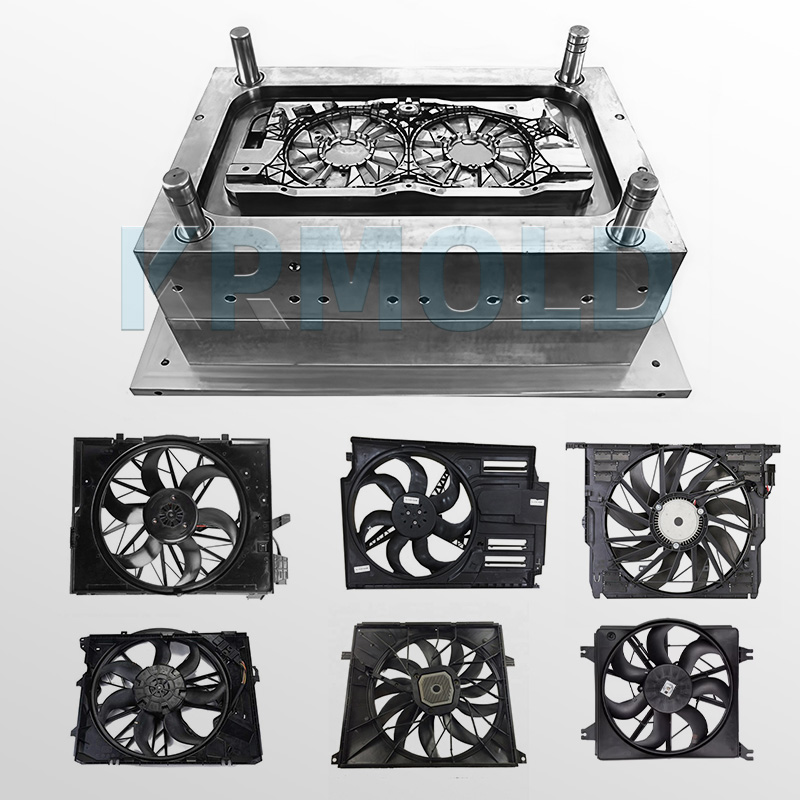

Definition of Automotive Fan Radiator Mould

——

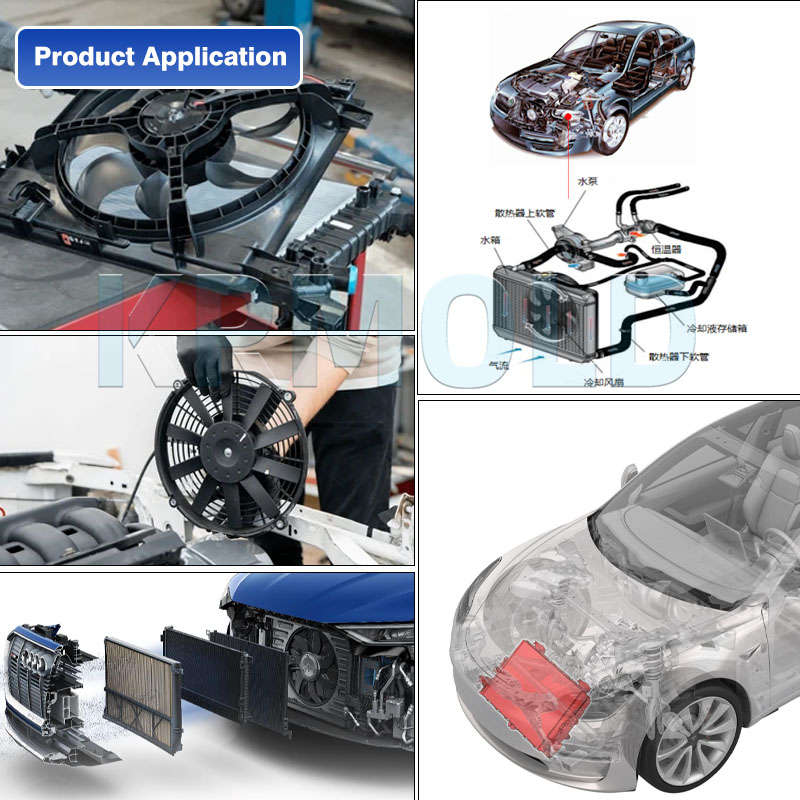

Automotive fan radiator mould enable the mass production of high-quality fans installed in automobiles. Their primary function is to help cool the engine, maintaining it at an optimal operating temperature to prevent overheating and potential malfunctions. KRMOLD provides high-quality car radiator fan shroud mould due to its extremely stringent requirements for mold materials and processing.

Because fan blades require high levels of balance and concentricity during high-speed operation, even minor errors can have serious consequences. Therefore, KRMOLD rigorously controls every step of the automotive fan radiator mould manufacturing process. Particular attention is paid to blade thickness, requiring absolute precision. All car radiator fan shroud mould processing is performed using high-precision, high-speed milling machines to ensure the quality of each component. After machining, all parts undergo rigorous dimensional inspection and verification to ensure compliance with design standards.

With over twenty years of experience, KRMOLD provides complete automotive fan radiator mould manufacturing solutions to numerous well-known automotive manufacturers. If you are working on a project and need to develop car radiator fan shroud mould or related products, please feel free to contact KRMOLD.

Features of Automotive Fan Radiator Mould

——

Generally, car radiator fan shroud mould and injection processes face several challenges, such as complex shapes and structures, material selection, and processing. Reasonable car radiator fan shroud mould design and manufacture as well as accurate control of injection parameters and cooling system help to surmount these problems to produce high-quality automotive fan radiator mould. Email kingreal2004@gmail.com for any questions; the KRMOLD team will respond in 12 hours.

Automotive Fan Radiator Mould Parameters:

| Core & Cavity Steel: | 2738 |

| Steel hardness: | HRC35-38 |

| Injection System: | SIDE GATE |

| Ejector System: | EJECTOR PIN |

| Cycle Time: | 45S |

| Tooling lead time: | 60 DAYS |

| Mold life: | 1,000,000 SHOTS |

Advantages of Car Radiator Fan Shroud Mould

——

1) High-quality materials for automotive fan radiator mould

The selection of materials for car radiator fan shroud mould is crucial. Carefully chosen materials not only improve the durability of the automotive fan radiator mould but also enhance the performance of the final product. Here are some commonly used mold materials and their performance characteristics:

Glass Fiber Reinforced Nylon (PA66-GF30): This material is widely used in car radiator fan shroud mould due to its excellent heat resistance and mechanical strength, making it particularly suitable for applications requiring high temperatures and high strength. Glass fiber reinforced nylon also has good corrosion resistance and rigidity, ensuring the durability and reliability of automotive parts. Its excellent performance allows automotive fan radiator mould to operate stably even under extreme conditions.

Polypropylene (PP): Polypropylene is a lightweight material with good heat resistance and chemical stability, as well as high impact resistance and rigidity. It is widely used in car radiator fan shroud mould because its excellent corrosion resistance allows it to withstand the challenges of various working environments, making it an ideal choice for producing durable automotive parts.

Polyphenylene Sulfide (PPS): Polyphenylene sulfide, with its excellent heat resistance, corrosion resistance, and mechanical properties, is an ideal material for manufacturing automotive parts in high-temperature environments. It is suitable for applications where automotive fan radiator mould need to withstand high temperatures and various pressures inside the engine compartment.

Polystyrene (PS) : This material excels in mold making, offering excellent molding properties and surface quality, making it suitable for automotive parts with high aesthetic requirements. For car radiator fan shroud mould, a good surface finish enhances the appearance and performance of the finished product.

Aluminum Alloys: For applications requiring higher strength and corrosion resistance, aluminum alloys offer an excellent choice. Aluminum alloys not only have low density and good thermal conductivity but also help reduce the overall weight of the vehicle, enabling lightweight design and improved fuel economy.

To guarantee that the final product possesses excellent physical characteristics and is affordable, one must thoroughly consider elements including the operating environment of the car radiator fan shroud mould, material cost, and processing efficiency when choosing the proper material.

2) Quality assurance for car radiator fan shroud mould

KRMOLD automotive fan radiator mould benefit from the combined effect of several key factors, ensuring that KRMOLD can provide high-performance car radiator fan shroud mould that meet diverse customer needs.

Advanced equipment for automotive fan radiator mould manufacturing: KRMOLD is equipped with comprehensive equipment, including state-of-the-art CNC machine tools, injection molding machines, and testing instruments. These machines not only meet customers' diverse needs in terms of production volume and complexity, but also strictly adhere to international standards, ensuring that the production process of each car radiator fan shroud mould is efficient and controllable. By introducing advanced technology and equipment, KRMOLD can guarantee the stability and reliability of quality at every stage of automotive fan radiator mould manufacturing.

Reduced wear for car radiator fan shroud mould: In the design and manufacturing process of automotive fan radiator mould, KRMOLD places particular emphasis on reducing the possibility of wear and damage. This includes careful selection of mold materials, and rational structural design and load distribution. KRMOLD strives to guarantee that during usage automotive fan radiator mould yield a smooth, flawless, and scratch-free surface, and this surface quality has a major influence on the look and operation of the finished product. Moreover completely ensured is the consistency of mold finish and texture, hence enhancing the general quality of automobile fan radiators.

Close collaboration: KRMOLD engineers work closely with customers from the early design stages, providing professional advice on material selection, feasibility studies, product geometry, cost-effectiveness, and car radiator fan shroud mould life through communication and collaboration. This close collaboration not only ensures that customer needs are fully understood but also identifies potential problems during the automotive fan radiator mould design phase, thereby reducing subsequent downtime, defects, and costs. Customer involvement at every step of the design process significantly improves car radiator fan shroud mould reliability and operability.

Preventative automotive fan radiator mould maintenance: KRMOLD preventative maintenance program also plays a crucial role. This includes regular car radiator fan shroud mould inspections, professional cleaning, refurbishment, steel replacement, and performance optimization. All maintenance work is meticulously documented and tracked to ensure consistent car radiator fan shroud mould quality throughout long-term production. Through continuous maintenance and monitoring, KRMOLD not only extends automotive fan radiator mould lifespan but also significantly reduces production failure rates, ensuring efficient and stable operation of customer production lines.

KRMOLD Advantages

——

1. High-quality car radiator fan shroud mould

2. Affordably priced automotive fan radiator mould

3. On-time delivery car radiator fan shroud mould

4. Comprehensive after-sales service for car radiator fan shroud mould

5. Strict quality control for automotive fan radiator mould

6. All car radiator fan shroud mould are produced using automated processes.

For more information, please contact KRMOLD.

1. Provide certificates for mold core and cavity steel.

2. Provide automotive fan radiator mould trial videos.

3. Mold process reports: Weekly reports, car radiator fan shroud mould trial videos, and samples are provided for your review.

4. Spare parts: Consumable parts are provided.

Why Choose KRMOLD?

——

1. KRMOLD offers a one-stop service from automotive fan radiator mould design to distribution.

2. Car radiator fan shroud mould have dual ISO certifications (ISO 9001:2015 and ISO 14001:2015).

3. Automotive fan radiator mould manufacturing includes precision technologies such as CNC machining, milling, and turning.

4. KRMOLD expertise covers everything from conceptual design to warp control in car radiator fan shroud mould design, and flexible production assembly.

5. KRMOLD can manufacture automotive fan radiator mould for a variety of materials used by customers, such as PVC, polyethylene, and polycarbonate.

Specify the type of plastic (e.g. PP, ABS) and post-processing requirements (e.g. spraying, silk-screen printing), and provide 2D or 3D plastic part drawings should be provided. At the same time, provide the production volume, appearance requirements, tolerance standards, etc.

Generally speaking, our engineers will start to prepare the quotation immediately after the customer provides the complete production requirements. Usually it takes about 1-3 days.

The lead time for regular injection molds is usually 30-60 days, and may be longer for complex molds. For example, the typical lead time for liquid silicone molds is around 60 days, covering design, manufacturing, mold testing, etc.

High-precision processing technology: High-precision equipment such as CNC machining centers (CNC) and electric discharge machining (EDM) are used to optimize the design process in combination with CAD/CAM software. Quality control: Inspection of key dimensions of the mold by Coordinate Measuring Machine (CMM) and verification of multiple sample batches during the trial molding stage. Material Selection: Use die steel with high wear resistance (e.g. H13, S136) and surface treatment (e.g. nitriding, chrome plating) for die nuts to extend the life.

After every 50,000 molds, check the guide pillar, ejector pin and other wear parts, and clean up the residual plastic and rust on the mold surface. Use high temperature grease for sliding parts (e.g. tilt top, slider) to reduce friction loss. Ensure that the water circuit is smooth and the temperature difference is ≤5℃ to avoid cracking of the mold due to thermal stress.

Mould cost of materials accounted for about 30-40% (such as 1 ton of P20 steel price of about 20,000 yuan), processing costs accounted for more than 50% (CNC labor hourly rate of about 80-150 yuan / hour). Small batch production can choose aluminum mold or simplify the structural design; more than 100,000 pieces is recommended to use carbide inserts to enhance life!

Mould injection products need to fully meet the design requirements (such as size, appearance), and can be continuous and stable production. Mold marking, inspection reports (such as material hardness test) and engineering drawings should be complete.

Mould steel (such as S136H, NAK80 and other imported materials cost more) and the type of mold embryo (aluminum mold short-term cost is low but short life) directly affect the cost, the use of CAD/CAE/CAM design technology, hot runner system, etc. will increase the upfront investment, but can enhance the long-term benefits (such as reducing the sprues, increase production capacity).