KINGREAL UNIVERSAL IND., LTD

Phone

+86-13702855825| In modern architectural electrical engineering, socket panels, as the terminal interface for power transmission, directly affect electrical safety and user experience. Especially in homes, offices, and public facilities, the stability and safety of sockets are crucial. The quality of socket panels is often inextricably linked to the switch socket plastic injection molds used in the manufacturing process. Therefore, designing efficient plastic plug socket injection mold becomes critical. This article will delve into the design requirements, core challenges, and considerations for customized switch socket plastic injection molds. |  |

1/Design Requirements for Switch Socket Plastic Injection Molds

1.1

High Precision Requirements

The hole spacing tolerance of the socket panel must be controlled within ±0.02mm to ensure perfect contact with the plug. Only by ensuring precise dimensions can electrical hazards such as poor contact and short circuits be effectively prevented. Therefore, the use of high-precision processing equipment and processes is necessary in the design of plastic plug socket injection mold.

1.2

Fast Production Cycle

In today's competitive market, rapid production is a crucial factor for the survival and development of enterprises. Mainstream switch socket plastic injection mold designs require an injection molding life of 800,000 to 1,000,000 cycles, and the molding cycle should be compressed to less than 20 seconds. This requires that in the design of switch socket plastic injection mold, we not only pursue the durability of the mold but also optimize the injection molding process to achieve high efficiency.

1.3

Safety Redundancy Design

Safety is paramount in socket design. The plastic plug socket injection mold design must comply with local national standards for anti-vibration structures to prevent external environmental damage to the socket panel. At the same time, in material selection, flame retardancy and high-temperature resistance should be prioritized to ensure safe use under extreme conditions.

1.4

Surface Treatment Standards

The surface treatment of the socket panel directly affects its appearance and user experience. A matte textured surface with an Ra value controlled within the range of 0.8-1.6μm can effectively prevent scratches and dirt accumulation, improving user satisfaction. Therefore, surface treatment processes are equally important in the design of plastic plug socket injection mold.

2/Core Design Challenges of Switch Socket Plastic Injection Molds

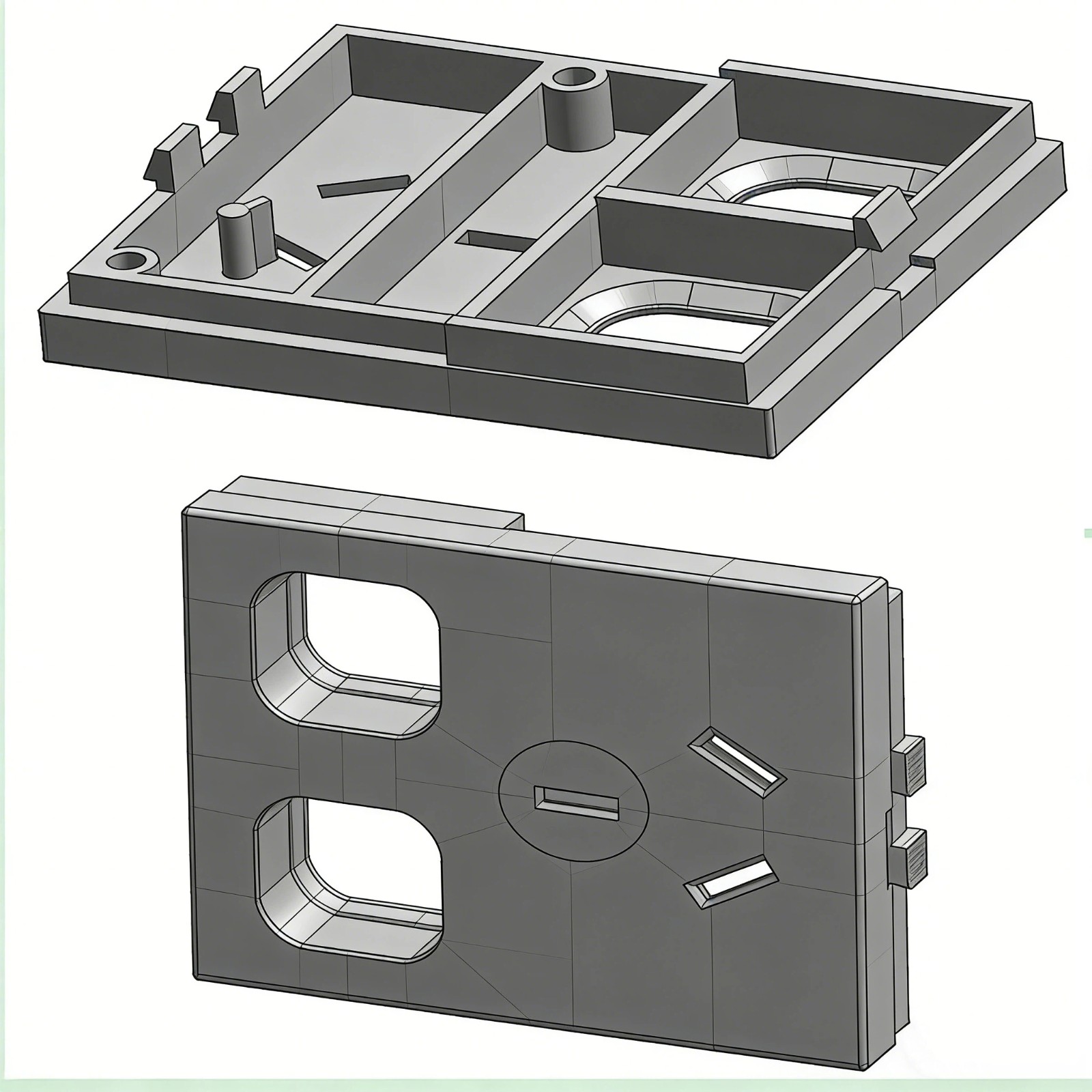

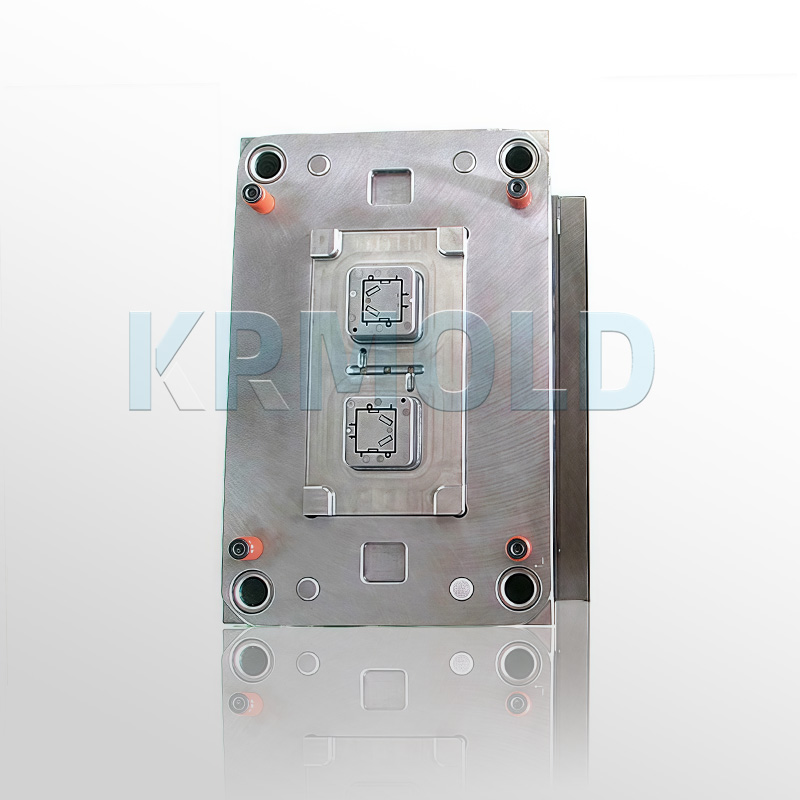

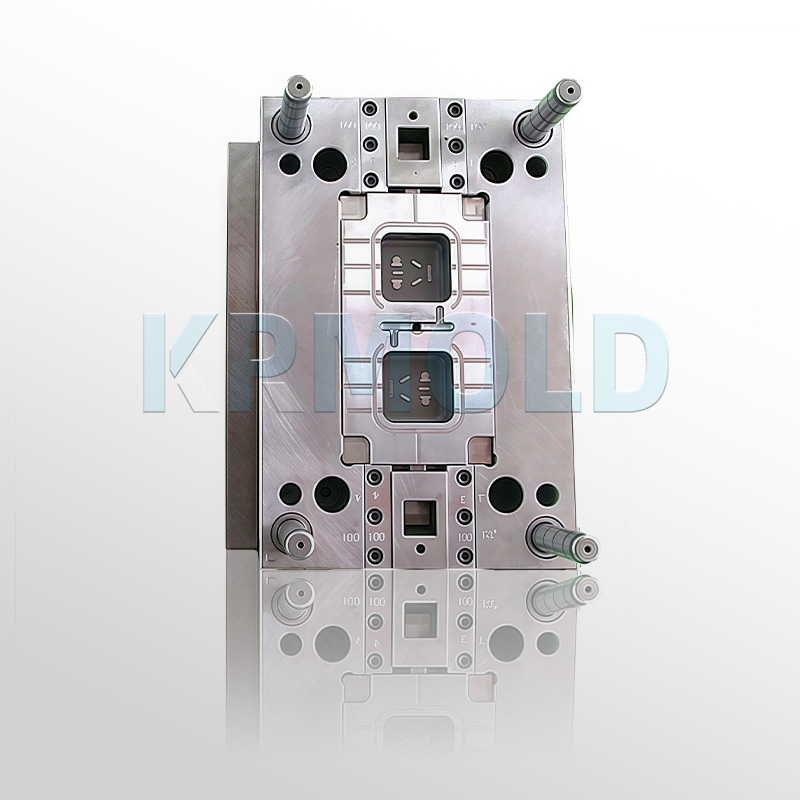

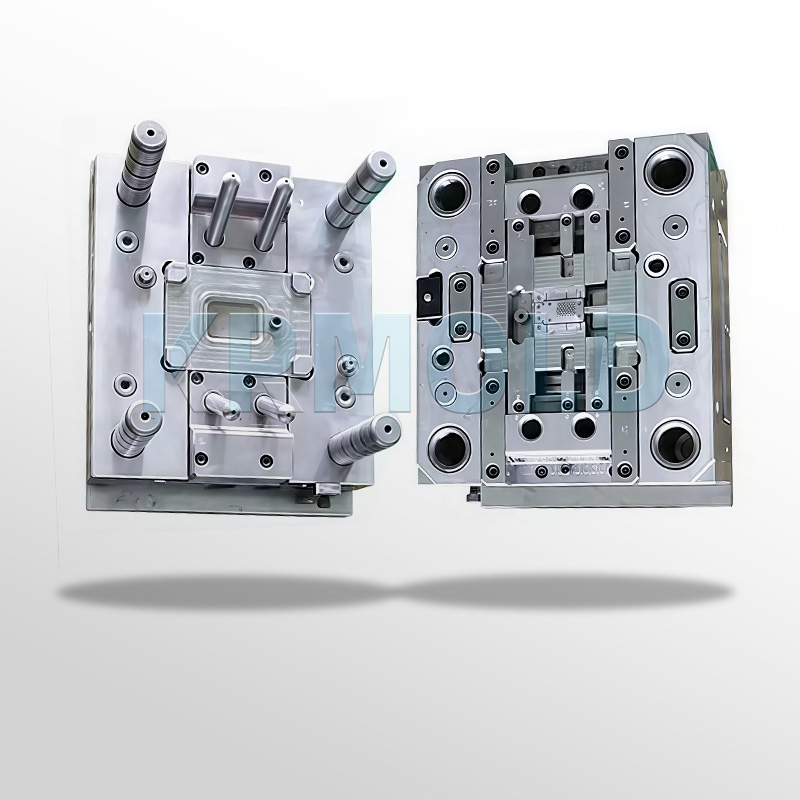

2.1 Complex Geometric Control Socket panel designs often involve complex geometric shapes, such as multi-port configurations (e.g., 5-hole sockets), undercut structures (snap-fit features), and thin walls (1-2 mm). Taking a 5-hole socket mold as an example, it requires achieving an accuracy of ±86 mm across five ports within a 0.2 × 86 mm area. This complexity places high demands on switch socket plastic injection mold design. To address this issue, the KRMOLD team frequently employs angled ejector pin mechanisms, typically set at an angle of 15°-25°, enabling damage-free demolding. Optimizing the parting line design, prioritizing the bottom surface of the panel to minimize visible seams, is also an effective means of improving mold design quality.

2.2 Material-Process Synergy Polycarbonate (PC) dominates due to its high strength (Vicat softening point ≥145°C) and flame retardancy (UL94 V-0). However, its high melt viscosity (307-317°C) and low shrinkage rate (0.5%-0.7%) present challenges for thermal control. Case studies show that a dual-loop temperature control system (with an accuracy of ±0.5°C) can significantly improve product quality, reducing warpage from 0.744 mm to less than 0.25 mm. Furthermore, the application of hybrid hot/cold runner systems, such as runners embedded with graphene, can limit melt temperature fluctuations to within ±3°C, greatly increasing the yield of 98.6-cavity molds. These are indispensable advanced technologies in plastic plug socket injection mold design. |  |

3/Switch Socket Plastic Injection Mold Materials and Surface Treatment Technology

Material selection directly affects plastic plug socket injection mold life and product quality. The following are commonly used materials and their processing techniques:

| Component | Preferred Material | Heat Treatment | Surface Treatment |

| Cavity/Core | S136 Mirror Steel | Vacuum Quenching HRC48-52 | Nano PVD Coating |

| Slide Rail | 8407 Hot Work Steel | Nitriding (0.1mm layer) | TD Treatment |

| Ejector Pin | SKD61 | Low-Temperature Treatment | DLC Coating |

4/Considerations for Customized Switch Socket Plastic Injection Mold Design

4.1 Shape and Size

Customized plastic plug socket injection mold design requires communication with the client to confirm the shape and size of the switch and socket housing to ensure product safety and durability. By injecting the appropriate materials into the switch socket plastic injection mold and processing with parameters such as pressure and temperature, the KRMOLD team can manufacture wall switches and sockets that meet user needs.

4.2 Regional Standards

Different countries and regions have different standard requirements for sockets to accommodate different types and specifications of power equipment. For example, the EU models common in European countries and the US models in the American market all need to be designed and manufactured according to the corresponding standards. This makes the development of plastic plug socket injection mold more complex, but also increases its market competitiveness.

4.3 Other Special Requirements

Switches and sockets with special functions such as fire resistance and waterproofing can be achieved by customizing corresponding switch socket plastic injection molds. This is important for meeting safety requirements and user convenience in different environments. Therefore, when designing plastic plug socket injection mold, the KRMOLD team will flexibly respond to various customer needs and tailor solutions.

KRMOLD specializes in plastic injection mold manufacturing and can provide various types of switch socket plastic injection molds. From high-precision requirements and safety design to material selection and surface treatment, KRMOLD takes every step seriously. Contact KRMOLD for more mold-related information.