KINGREAL UNIVERSAL IND., LTD

Phone

+86-13702855825| 1 | Design Requirements of Surgical Instrument Injection Molds |

| 2 | Design Process of Surgical Instrument Injection Mold |

Surgical instrument injection molds can process plastic products of different types and specifications, which has the characteristics of rapid prototyping and mass production and meets the standardization requirements of medical industry. Among them, the production of medical device injection mold is highly precise, which directly determines the quality and safety of medical equipment. Therefore, this article introduces the design basis of surgical instrument injection molds from the perspective of KRMOLD engineers.

1.Design Requirements of Surgical Instrument Injection Molds

(1) High precision requirements for surgical instrument injection molds

The size and shape accuracy of medical devices produced by medical device injection mold need to reach extremely high standards. Taking the surgical instrument injection molds as a n example, the matching accuracy between the piston and the syringe directly affects the accuracy of injection dosage, and the dimensional deviation usually needs to be controlled within ±0.05mm, which is more stringent in some scenes. At the same time, the medical device injection mold needs to accurately shape the complex three-dimensional structure of the instrument, whether it is a fine groove, a hole or a special curved surface, and the shape must be accurate and consistent, so as to ensure that the fit and effectiveness of the instrument can meet the standards in clinical use.

(2) High cleanliness requirements for surgical instrument injection molds

In the selection of medical device injection mold materials, it is necessary to select high-quality, non-toxic and corrosion-resistant mold materials (such as stainless steel) to avoid releasing harmful substances during injection molding and to ensure that the surgical instrument injection molds will not rust and deform after long-term use and cleaning and disinfection. In the environment of medical device injection mold manufacturing, mold manufacturing and use need to be carried out in clean workshops of 10 thousand level and above.

(3) Good surface quality requirements for surgical instrument injection molds

The surface roughness of the medical device injection mold should be controlled at Ra0.2-Ra0.4μm to make the surface of the instruments smooth, easy to clean and disinfect, and avoid adsorbing bacteria and viruses. At the same time, there must be no defects such as scratches, sand holes and air holes on the surface of the medical device injection mold.

(4) Compliance with regulations and standards for surgical instrument injection molds

Medical device injection mold manufacturing should strictly follow ISO 13485 medical device quality management system standards, FDA regulations and other relevant laws and regulations to ensure compliance in the whole process of design, manufacture and use. At the same time, the surgical instrument injection molds should have good traceability, and keep design drawings, manufacturing process records, raw material procurement information, use and maintenance records, etc., so as to facilitate traceability analysis when there are problems with the equipment.

2.Design Process of Surgical Instrument Injection Mold

(1) Medical device injection mold design preparation

-Product design confirmation: KRMOLD engineers will determine the appearance, size and internal structure of medical equipment according to its functional requirements, and at the same time consider practicality, durability and production convenience to ensure that the product design meets the use and production requirements.

-Material selection: KRMOLD engineers will choose materials that meet the standards of medical industry, such as medical stainless steel and specific polymer materials.

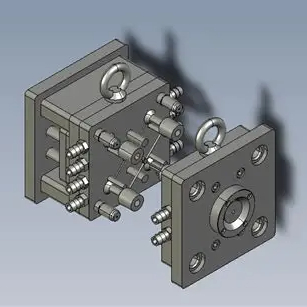

-Mold structure planning: KRMOLD engineer will carefully plan the basic structure of the medical device injection mold, including parting surface, gating system and cooling system, so as to lay the foundation for efficient production and product quality.

(2) Surgical instrument injection molds processing and manufacturing

-Mould parts processing: According to the design drawings, KRMOLD staff use CNC machine tools, spark machines and other equipment to process parts. During the process, they use CMM and micrometer to monitor the dimensional accuracy and surface roughness to ensure that they meet the design requirements.

-Assembly and debugging: the parts are assembled in a clean and dust-free environment, and the cavity, core and guide mechanism are assembled accurately. After assembly, the medical device injection mold is opened and closed manually or by equipment to check whether the movement is smooth and there is no jamming.

-Verification of mold trial: Before formal production, KRMOLD engineer will conduct surgical instrument injection molds trial to simulate the actual injection conditions, check the rationality of surgical instrument injection molds structure, machining accuracy and demoulding, and provide a basis for subsequent debugging.

(3) Surgical instrument injection molds debugging and correction

-Performance debugging: KRMOLD engineers will adjust the surgical instrument injection molds performance according to the test results. If the cooling is uneven, the cooling channel will be optimized, and if the filling is not smooth, the gating system will be adjusted to improve the production efficiency and product quality.

-Dimension correction: Measure the dimension deviation of the trial medical device injection mold products with precision instruments, and fine-tune the parts with appropriate processing methods in combination with the mold structure to ensure the accuracy of the instrument dimensions.

-Surface treatment: polish and electroplate the surgical instrument injection molds to improve the product appearance and medical device injection mold performance.

If you are interested in medical device injection mold and want to get more relevant information, please feel free to contact KRMOLD!