Injection Mold for Steering Wheel

● ● ● ● ●

Injection mold for steering wheels are specifically designed to produce durable and high-precision plastic steering wheel parts, a crucial component for steering control during vehicle operation. Ensuring a safe and effective driving experience, these car steering wheel injection molds work for all car models.While also taking into account durability and dependability, KRMOLD injection mold for steering wheel designs give equal weight to both the appearance and comfort of the steering wheel to guarantee great performance even after extended usage.

KRMOLD injection mold for steering wheel offer flexibility in complex geometric designs and are compatible with a variety of materials. These car steering wheel injection molds satisfy customers' varied needs as well as the changing trends of the current automotive sector thanks to their great accuracy, extended lifetime, and adaptability. If you have any queries, please email kingreal2004@gmail.com. Giving prompt and superior service, the KRMOLD team will make sure a response is given within 12 hours.

Parameters of Injection Mold for Steering Wheel

● ● ● ● ●

| Mold Type | Car Steering Wheel Injection Mold |

| Mold Material | P20/718/738/NAK80/S136 |

| Mold Base | HASCO, DME, MISUMI, JIS, LKM, etc. |

| Runner | Cold Runner/Hot Runner |

| Gate | Sliding Gate/Sub-Gate/Pin Point Gate |

| Cavity | Single Cavity/Multi-Cavity |

| Design Software | UG/PROE/CAD/SOLIDWORKS |

| Molding Equipment | CNC, Wire Cutting, Milling, EDM |

| Raw Materials | ABS, PP, PC, PA6, PA66, PVC, POM, PMMA, PS, etc. |

| Packaging | Wooden Pallet, Carton |

| OEM/ODM | Welcome, please provide 2D/3D files or samples |

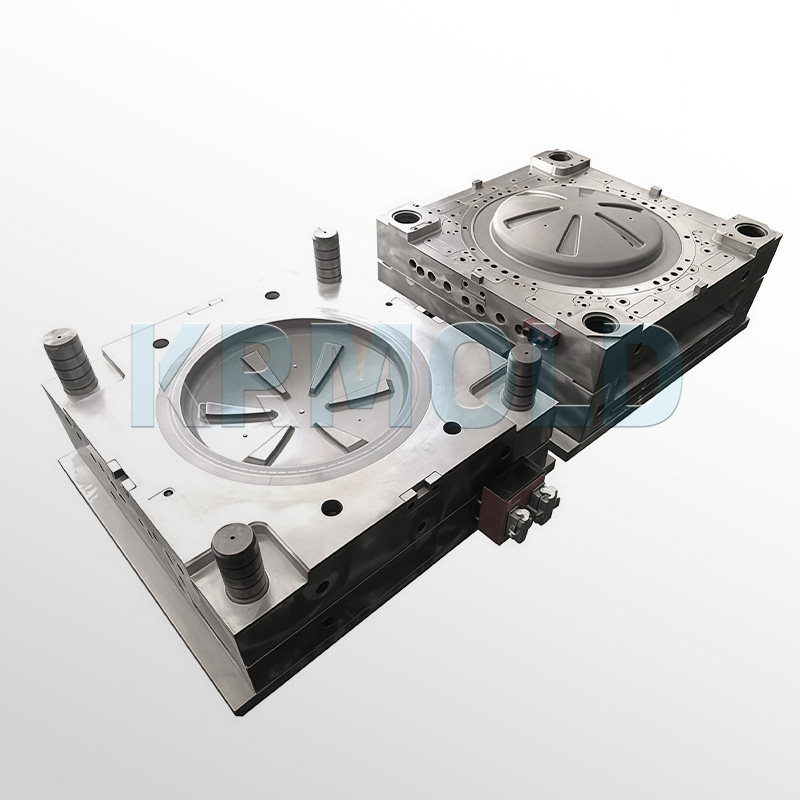

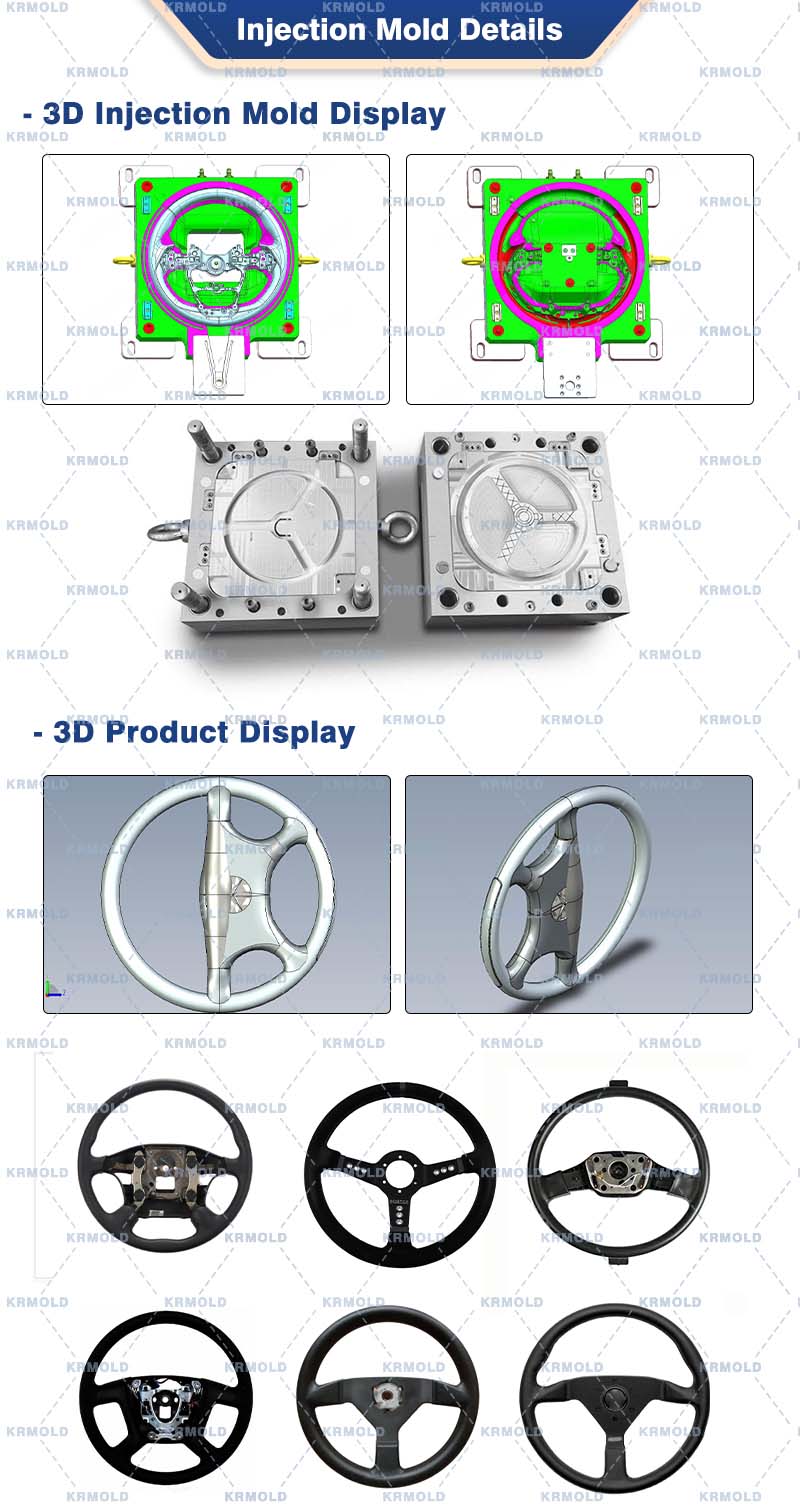

Injection Mold for Steering Wheel Design

● ● ● ● ●

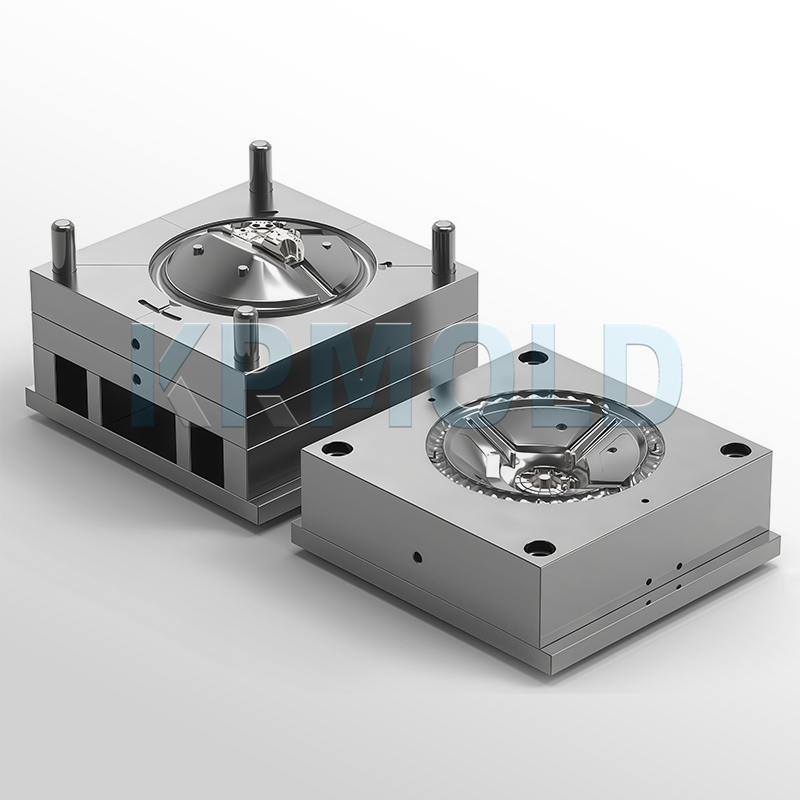

Mold flow analysis and mold design for car steering wheel injection mold are crucial steps in automotive interior manufacturing. Scientific mold flow analysis and meticulous mold design directly impact the quality, appearance, and production efficiency of injection-molded products.

(1)Mold flow analysis of car steering wheel injection mold 1/ Mold flow analysis import: When conducting mold flow analysis for an automotive steering wheel, the first step is to import the steering wheel's CAD model using mold flow analysis software. Simultaneously, injection molding process parameters, such as injection speed, temperature, and pressure, must be set for subsequent analysis. 2/ Injection molding process simulation: Through mold flow analysis, the system simulates key steps in the injection molding process, including melt flow, filling, and cooling. The simulation results can be used to evaluate the steering wheel's filling performance, identify potential defects such as bubbles and short shots, and optimize injection molding process parameters accordingly, ensuring that every detail of the steering wheel meets the expected standards.

The following key points require special attention in mold flow analysis: - Filling performance guarantee: Optimizing injection molding process parameters to ensure excellent filling performance and avoid similar defects is a prerequisite for obtaining a high-quality automotive steering wheel. - Cooling system design: A well-designed cooling system provides excellent cooling during injection molding, improving production efficiency and product quality, and ensuring the integrity of the molded steering wheel. - Demolding system design: Designing a suitable demolding system based on the shape and requirements of the steering wheel is crucial. This not only ensures smooth demolding but also effectively prevents damage and deformation, improving injection mold for steering wheel versatility and lifespan. - Injection sequence and position: Determining the appropriate injection sequence and injection point positions is a key design consideration to ensure the plastic material fully fills the mold cavity, avoiding voids and defects. |  |

| (2)Car steering wheel injection mold design 1/ Car steering wheel injection mold design principles: When designing a injection mold for steering wheel, all design requirements of the steering wheel must be fully considered—including the mold cavity, mold core, demolding system, and cooling system. 2/ Precision and dimensional control: Precision and dimensions are core factors affecting the quality and stability of the automotive steering wheel. Ensuring injection mold for steering wheel accuracy directly affects the final quality and performance of the steering wheel. 3/ Car steering wheel injection mold design using CAD software: CAD programs helps to produce three-dimensional models and engineering drawings of the injection mold for steering wheel throughout the design process, which makes the design more intuitive and simpler to maximize.This method builds a solid base for later component processing and verification as well as design precision improvement.

The following tasks also need to be completed during car steering wheel injection mold design: - Machining accuracy and dimensional control: Ensure the machining accuracy of mold parts meets requirements to guarantee injection molding quality. - Mold surface treatment: To improve the surface quality and smoothness of the steering wheel, appropriate surface treatments such as grinding and polishing are usually required. - Durability and maintainability considerations: By rationally designing the car steering wheel injection mold structure and components, the durability and maintainability of the injection mold for steering wheel are improved, thereby reducing downtime and maintenance costs. This allows the car steering wheel injection mold to maintain a high-efficiency production state. |

Application of Car Steering Wheel Injection Mold

● ● ● ● ●

Why Choose KRMOLD?

● ● ● ● ●

1)Strength of the R&D team: KRMOLD boasts a strong R&D team. From plastic parts to car steering wheel injection mold design, the KRMOLD crew performs thorough analysis, research, and quality control at every level. KRMOLD continuously optimizes its design and processes to achieve the highest industry standards, ensuring that customers receive leading-edge injection mold for steering wheel in terms of quality and performance.

2)High-precision measurement equipment: To guarantee the precision of injection mold for steering wheels, KRMOLD is equipped with advanced coordinate measuring machines and projection measuring instruments. These devices are used to meticulously inspect the dimensions of all parts, including the mold blank, core, and inserts, ensuring that each meets qualified standards to guarantee the quality and stability of the final product.

3)Multi-tonance injection molding machine support: KRMOLD possesses injection molding machines of various tonnages, sufficient to meet the manufacturing needs of various injection mold for steering wheel. This ensures that new car steering wheel injection molds can undergo T1 trial molding promptly after completion, allowing for rapid identification of problems and the development of improvement solutions. KRMOLD values every detail, thus providing customers with continuously optimized injection mold for steering wheel production services.

FAQ About Car Steering Wheel Injection Mold Manufacturing

● ● ● ● ●

Q1: What type of steel do you use to manufacture car steering wheel injection molds?

A1: KRMOLD can use any type of steel specified by the customer or commonly used in the market, such as P20, 718, 8407, NAK80, H13, S136, DIN 1.2738, DIN 1.2344, etc.

Q2: Can you provide steel certificates and heat treatment certificates?

A2: Yes, KRMOLD can provide steel certificates or hardness certificates as proof to ensure that the materials used by KRMOLD meet relevant standards.

Q3: What is the delivery time for injection mold for steering wheel?

A3: The delivery time depends on the size and complexity of the car steering wheel injection mold. Normally, the delivery time is 25-45 days. If the car steering wheel injection mold is relatively simple and small in size, the KRMOLD team can complete it within 15 days.

Q4: Do you provide spare parts for customers?

A4: If the customer needs them, KRMOLD will offer spare components for the car steering wheel injection mold to guarantee that customers can get quick solutions for any problems noticed during subsequent usage.

Specify the type of plastic (e.g. PP, ABS) and post-processing requirements (e.g. spraying, silk-screen printing), and provide 2D or 3D plastic part drawings should be provided. At the same time, provide the production volume, appearance requirements, tolerance standards, etc.

Generally speaking, our engineers will start to prepare the quotation immediately after the customer provides the complete production requirements. Usually it takes about 1-3 days.

The lead time for regular injection molds is usually 30-60 days, and may be longer for complex molds. For example, the typical lead time for liquid silicone molds is around 60 days, covering design, manufacturing, mold testing, etc.

High-precision processing technology: High-precision equipment such as CNC machining centers (CNC) and electric discharge machining (EDM) are used to optimize the design process in combination with CAD/CAM software. Quality control: Inspection of key dimensions of the mold by Coordinate Measuring Machine (CMM) and verification of multiple sample batches during the trial molding stage. Material Selection: Use die steel with high wear resistance (e.g. H13, S136) and surface treatment (e.g. nitriding, chrome plating) for die nuts to extend the life.

After every 50,000 molds, check the guide pillar, ejector pin and other wear parts, and clean up the residual plastic and rust on the mold surface. Use high temperature grease for sliding parts (e.g. tilt top, slider) to reduce friction loss. Ensure that the water circuit is smooth and the temperature difference is ≤5℃ to avoid cracking of the mold due to thermal stress.

Mould cost of materials accounted for about 30-40% (such as 1 ton of P20 steel price of about 20,000 yuan), processing costs accounted for more than 50% (CNC labor hourly rate of about 80-150 yuan / hour). Small batch production can choose aluminum mold or simplify the structural design; more than 100,000 pieces is recommended to use carbide inserts to enhance life!

Mould injection products need to fully meet the design requirements (such as size, appearance), and can be continuous and stable production. Mold marking, inspection reports (such as material hardness test) and engineering drawings should be complete.

Mould steel (such as S136H, NAK80 and other imported materials cost more) and the type of mold embryo (aluminum mold short-term cost is low but short life) directly affect the cost, the use of CAD/CAE/CAM design technology, hot runner system, etc. will increase the upfront investment, but can enhance the long-term benefits (such as reducing the sprues, increase production capacity).