KINGREAL UNIVERSAL IND., LTD

Phone

+86-13702855825| 1 | Working Principle of Smart Device Housing Injection Molding |

| 2 | Advantages of Smart Device Housing Injection Mold |

| 3 | Why Choose KRMOLD Smart Device Housing Injection Molds? |

| With the rapid rise of fashionable smart devices, innovative solutions for smart device housing injection molds have become increasingly important. These solutions not only focus on the aesthetic appeal of the equipment, but also need to ensure its durability and efficiency. The shells produced by smart device shell injection molds have become leading solutions with significant advantages in sustainability and functionality. This article will delve into the working principle, advantages of smart device housing injection mold, and why KRMOLD is chosen as the preferred choice for smart device shell injection mold production. |  |

1.Working Principle of Smart Device Housing Injection Molding

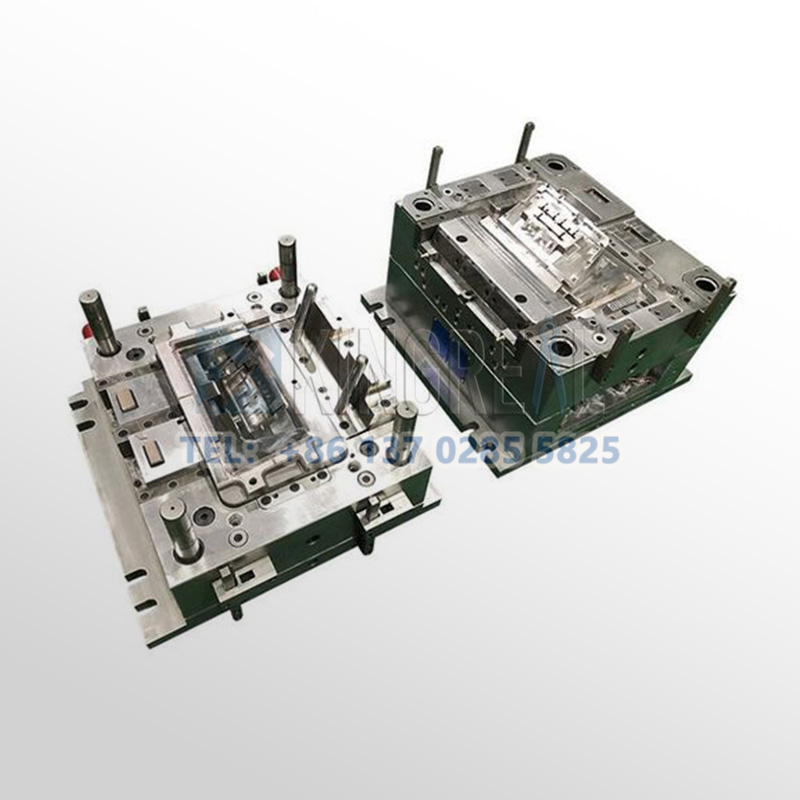

Smart device shell injection molding is a production process in which raw materials are plasticized and injected into smart device housing injection molds to form specific shapes. Its working principle mainly consists of several steps:

-Heating material: First, heat the plastic particles to a viscous and malleable state. This process involves high temperature and pressure to bring the material to a molten state.

-Injection into the smart device shell injection mold: The molten material is then injected into a precisely designed mold cavity, the shape and size of which determine the appearance and functionality of the final product.

-Cooling and solidification: After filling is completed, the mold will be cooled. The molten material solidifies during the cooling process to form the final shell product.

-Demolding: Finally, the mold is opened and the product is removed, completing the entire smart device housing injection molding process.

2.Advantages of Smart Device Housing Injection Mold

2.1 Mass production for smart device shell injection mold The smart device housing injection molds support mass production, enabling manufacturers to respond quickly to changes in market demand. The advantage of this production method lies in that manufacturers can produce a large number of shells in a short period of time to meet the market demand for smart phones, tablet computers and various smart home devices. Through smart device shell injection molds, the production process can be automated, significantly enhancing production efficiency. Compared with traditional production methods, smart device housing injection molding not only saves labor costs but also shortens the production cycle.

2.2 High precision for smart device shell injection mold The smart device housing injection molds can ensure the strict tolerances required for the shells of the devices, reducing quality problems caused by deviations. Through high-precision production processes, the smart device shell injection molds can reproduce known detailed features, thereby enhancing the appearance and functionality of the devices. |  |

2.3 Reduce weight of the casing The casing produced by KRMOLD smart device housing injection molds helps to reduce the overall weight of the equipment, making it more lightweight and portable. This feature is particularly important in today's highly competitive consumer electronics market. Consumers usually prefer lightweight products because it makes them more convenient to use. The lightweight design not only enhances the user experience but also reduces transportation costs, further strengthening the market competitiveness of the product. 2.4 Improve heat dissipation performance KRMOLD engineers carry out personalized design for the smart device shell injection molds to enhance heat dissipation. This is crucial for maintaining the performance of the equipment and extending its service life. As the functions of smart devices improve, the heat generated inside the devices also increases. Heat dissipation issues have become an important factor affecting the performance of the devices.

2.5 Enhance aesthetic value The smart device housing injection molds can meet consumers' high demands for appearance. When consumers choose products, they are often attracted by the appearance of the products. Therefore, attractive design can effectively enhance the brand image and increase market share. KRMOLD smart device shell injection mold design team closely integrates with market trends and is capable of providing customers with design solutions that meet today's aesthetic standards. Through meticulous selection of materials, colors and shapes, KRMOLD helps customers achieve personalized expression of their brands, making their products more recognizable in the market. |  |

3.Why Choose KRMOLD Smart Device Housing Injection Molds?

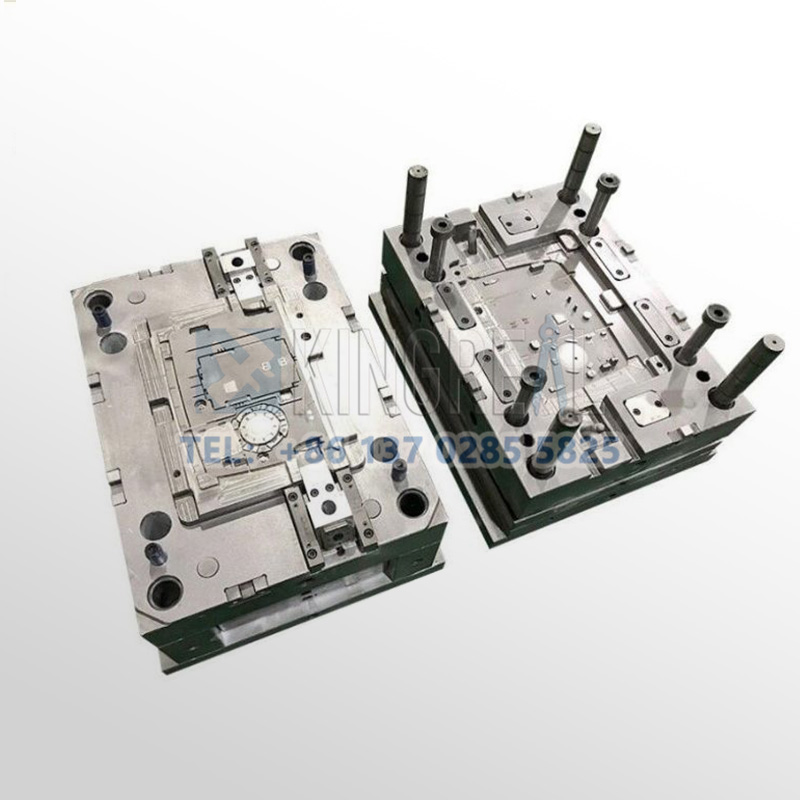

3.1 Professional smart device shell injection mold design KRMOLD has over 500 plastic injection mold design project experiences and is capable of comprehensively understanding the product characteristics of various industries. No matter what the customers' demands are, KRMOLD can provide tailor-made smart device housing injection mold solutions. KRMOLD engineers combine market trends with customer demands to ensure that each smart device shell injection mold has the best performance.

3.2 Excellent lifespan for smart device housing injection mold KRMOLD carefully selects smart device shell injection mold materials and employs advanced processes to ensure its plastic molds have a lifespan of over 300,000 cycles. This durability means customers receive a higher return on their investment during production. The smart device housing injection mold's durability not only reduces production costs but also reduces the frequency of smart device shell injection mold changes, further improving production continuity. |  |

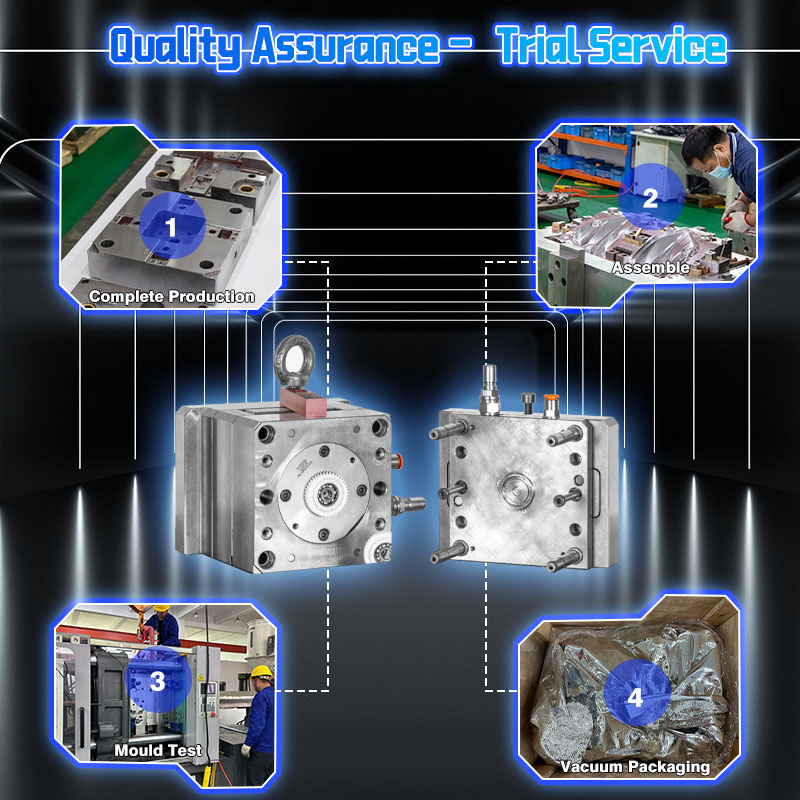

3.3 Strict quality control for smart device housing injection mold KRMOLD implements a variety of advanced smart device shell injection molding testing equipment and a rigorous 12-step quality control process to ensure consistent mold quality. KRMOLD team of professional quality engineers uses high-precision testing equipment to rigorously control every step, guaranteeing 99% smart device housing injection mold quality. This quality assurance provides customers with peace of mind when using KRMOLD products and reduces after-sales issues caused by quality issues.

3.4 Fast volume delivery for smart device shell injection mold KRMOLD provides one-stop services for smart device housing injection mold development, smart device shell injection mold manufacturing, and plastic injection molding, ensuring fast mold turnaround and timely delivery. From order acceptance and design to production, we provide comprehensive support to ensure customers receive their desired products in the shortest possible time. The ability to quickly deliver enables manufacturers to seize opportunities in the market and quickly meet customer needs. |  |